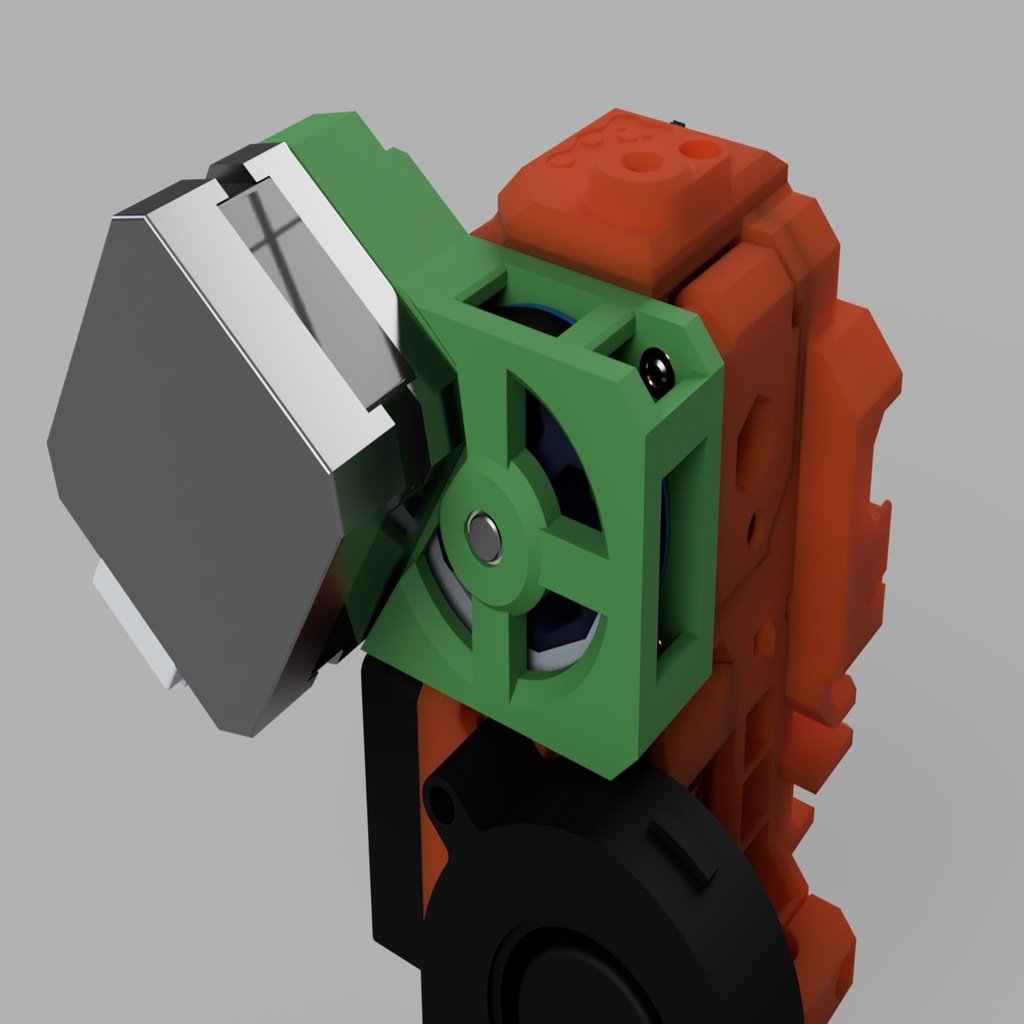

Nema 17 Gearbox "Pulleybox" Mod for Extruder

thingiverse

4/27/2020: Latest versions have been updated, can consider these a "Release Candidate", fixed the hex nut version holes (they were 4.2mm instead of 3.3mm for screw), 4.2 is the sized for the heatserts and I missed that when remaking this derive, oops? Slight redesign of screw pockets for motor, a little more plastic and squared it off. Added draft to the "spokes" to help bridging. Adjusted outside bearing pocket by .1mm, now matches the inside bearing pocket of 4mm deep. Spacer is a little larger for a tighter wheel fit (in addition to the bearing pocket adjustment), the v3 spacer is also easier to slip onto the shaft as the ID is bigger (5.5mm), and added more surface area to the part that touches the wheel. Spacer is here to stay, I didn't like the compromises of no spacer design. Many thanks to Grégoire and Florian for testing and providing critical feedback to these changes. STLs included for now only, will share updated STEP and fusion later. Soon hope to create, BOM, print settings, and assembly guide. Stay tuned for that. 4/19/2020: Another update to the single piece, older version would not allow you to tighten fully depending on how deep the flat is on your shaft. 4/18/2020: Updated the single piece to b2 release, made the wheel tread thicker (6.6mm instead of the 6.1mm that skele wheel and Zaribo wheel use), added a new spacer which has a little larger ID and larger OD as well to make it easier to install. Still a PITA, so I'll continue to investigate a design that requires no spacer (fingers crossed) 4/16/2020: So there is a new gearbox design on the block, it's the Zaribo geared extruder https://www.thingiverse.com/thing:4211132, I really like some of the things done here, especially the single piece wheel with the M3x8 screw pocket on the back! So of course, I made my own. Uploaded new part Single_Piece_Wheel_b1.stl, but I have not been able to test this in a gearbox yet. It should work though, still need a spacer, but I might look into some of the other things that Zaribo gearbox has done as well. Nice job 7/19/2019: I had a situation where my 870 PLA Skelestruder wheel broke, I'm sure it's because I over tightened it but I decided to remix it to beef it up a little. I also recommend printing this part in PETG now as well. 12/10/2019: I have ordered some shafts from misumi, this is the part https://us.misumi-ec.com/vona2/detail/110302634310/?HissuCode=SSFJ5-45-A6-E6-WFC11, this shaft should be compatible with the gearbox and is also compatible with skelestruder. The flats are just longer to allow more universal usage. I'll update once I have tested. 10/5/2019 Update: The gearbox has been redone from the ground up, now supports motors with longer shafts like the LDO .9 degree pancake stepper without having to cut the end of the motor shaft off. 9/3/2019 Update: Made a few optimizations to strengthen a few areas, especially for the hex nut version as a tester had the edge crack. For hex nut version I have made the hex nut cavity a little larger and added some additional plastic to reinforce the hext nut pockets. I recommend using the heatsert version (it's what I use), but if you decide to use hex nuts this new update should be better for you. I really loved the "Bunny Science Extruder Motor Gearbox" by BunnyScience. I used it for a while with a few minor modifications but BunnyScience moved on to making complete extruders so I wanted to make some additional refinements. This mod works effectively the same way but there are some changes in the design to slightly improve (per my opinion). I also really liked the look of knoopx's design but on my extruder the gearbox interfered with the hotend fan. Changes from Bunny Science Extruder Motor Gearbox * Better optimized for 3d printing, prints with no supports and the geometry should print using bridges instead of sloped overhangs. * Less plastic making it 30% lighter (19 grams vs 27 grams) * I'm using this on a bear extruder, and a bear extruder is happier with chamfers instead of fillets :D * The BunnyScience design belt was a little too tight for me and the 16T pulley had to be almost right on the motor to prevent the belt from rubbing, I moved the motor out a little to allow more room here. * I just think it looks better, but this is just my opinion. ---- Materials (This is basically the same as the BunnyScience gearbox) * 1 x 5 mm shaft rod shaft with two flats ground 0.35 to 0.4 mm deep (STL for Jig is provided) Length 45 mm * 2 x 105ZZ bearings * 1 x continuous loop 140-2GT-6 Timing Belt * 4 x M3 hex nuts * OR 4 x M3 Heatserts https://www.aliexpress.com/item/32685038721.html?spm=a2g0o.productlist.0.0.512757deHEsNqO OR https://www.aliexpress.com/item/32803818118.html? * 1 x M3 square nut * M3 * 6mm screw (set screw for wheel) (JLTX Wheel, see skelestrruder guide for more details on this step) * 3 x M3*18mm Screws * 3 x M3 washers * 1x16T drive pulley Assembly is basically the same as the Bunny Science gearbox. Prusa FW Settings For 1.8 degree stepper you will want to use 1/16 microstepping on the E axis, for a .9 degree stepper motor use 1/8 microstepping. And with both you would want to use 490 esteps Example M350 E16 ; sets microstepping to 1/16 M92 E490 ; sets esteps to 490 M500 ; save to eeprom You can verify your current settings by issuing M503

With this file you will be able to print Nema 17 Gearbox "Pulleybox" Mod for Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nema 17 Gearbox "Pulleybox" Mod for Extruder.