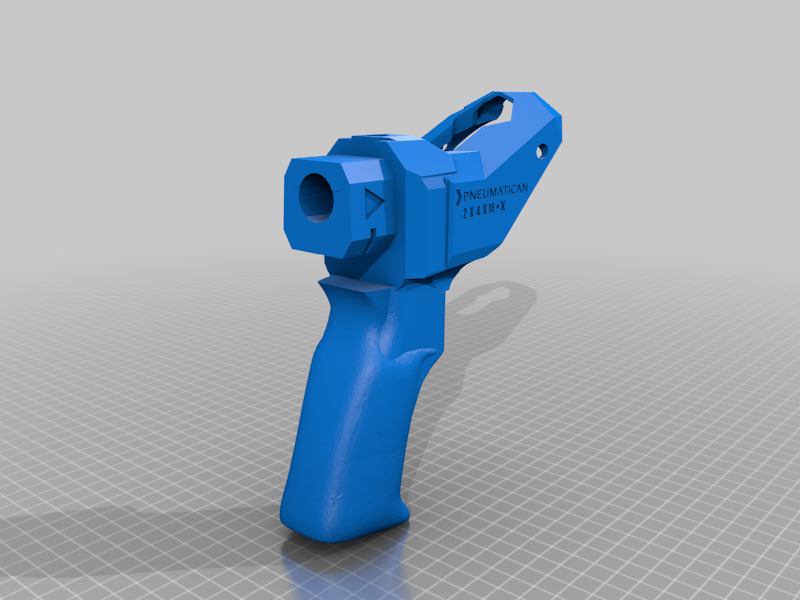

NERF 2x4x16 X ROUGHCUT

thingiverse

The 2x4x16 X ROUGHCUT is a 2.0 version of the original found here https://www.thingiverse.com/thing:2927669 Photo of printed 2x4x16 X ROUGHCUT in the wild below... https://www.instagram.com/p/B8Ffuush189/ You must permanently cut your Rough Cut handle off. We used a hand miter saw with a fine blade = fast work. No disassembly, or other modifications of the blaster required. You will need two - SET SCREW SOCKETS 6mm x 12mm #6 PLAIN STEEL- I picked up a set at Home Depot, - CROWN BOLT INC - brand. These screws will self thread & mate beautifully into the original screw holes, while maintaining the original blaster screws in place. This model is tight, creating a very ridged platform with no wiggle. You will need the proper sized hex key to install the set screw sockets. You will need to apply pressure to the stock system to line up the screw holes & install the set screws. Take caution not to over tighten the set screws and strip the plastic. If your holes will not align, you may have to cut more handle material off the blaster. Install the set screw closest to the handle first. Second, install the set screw that is near the top rail of the model. There is a third hole that will accommodate older versions of the Rough Cut as they changed the design at some point and moved the second screw. (Note: There are two ovals, one on each side. these ports are for viewing the priming indicators. These ovals are not screw holes.) A single piece of (19mm x 24.6mm) length of aluminum tubing inserts into the stock attachment point & dramatically increases the structural integrity of the stock system. There are some points at the top of the grip that I decided to smooth out with a razor and some fine grit sand paper. All our prototyping was flushed out on a MB Z18 using PLA. The final models were outsourced and printed on a very precise machine in ABS. I found that the Makerbot printing in PLA was adequate but required a good bit of fiddling to establish a good fit & finish. PLA MODEL PRINTS OF THE 2X4x16 X ROUGHCUT STOCK SYSTEM REQUIRE REINFORCEMENT. The aluminum reinforcement noted above is instrumental in the stock system's ability to defend against cracking. If a 3D printer is not calibrated or printing poorly, the prints may not be accurate and the hole for the aluminum support might be to tight. If your aluminum support does not fit, make sure your aluminum cuts are free from burs. Sanding the model to assist with assembly may be necessary. & as always, calibrate and fine tune your machine before printing. The ABS model proved to be a bit more durable on this build and the higher end printer delivers a superior product with precision dimensions. With everything put together the 2x4x16 X ROUGHCUT stock system is very tight and very rigid. Printed with the grip facing up. If your trigger is sticky after the install, smooth out the inside of the model where the trigger guard meets the model. Smooth out any high spots with a razor until the trigger returns completely on its own. Its a tight fit and we like it that way. Nerf stocks fit perfectly and our stocks are a very tight fit, as expected. A shout out to Kittka https://www.thingiverse.com/thing:53823 for the stock attachment point

With this file you will be able to print NERF 2x4x16 X ROUGHCUT with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on NERF 2x4x16 X ROUGHCUT.