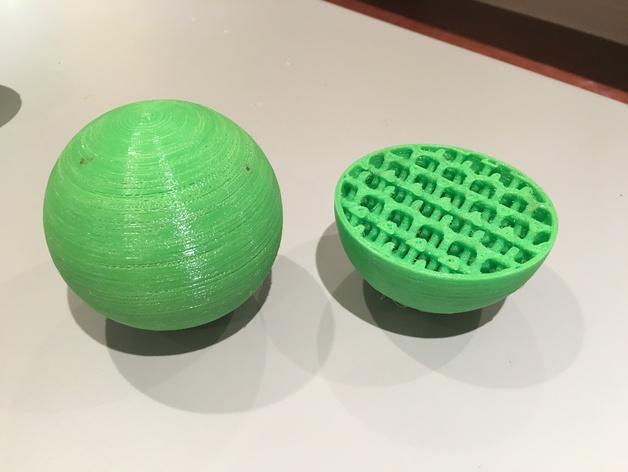

NinjaFlex Bouncy Balls with Internal Lattice

thingiverse

When I got NinjaFlex working on my 3D printer, my first goal was was to make a bouncy ball. I was disappointed when due to the 2D infill provided by my slicer, the ball was not consistent in how high or where it bounced. By using Maker Muse's method for creating even, 3D infill, I was able to engineer a better bouncy ball. Video: https://youtu.be/JWwllOorjUw Here is a list of the different versions you can download and how they are different: Version 0: This was the first attempt at making a NinjaFlex bouncy ball. It is just a plain sphere and does not bounce well or consistently. It bounced anywhere from 1' 10" to 2' 8" Version 1: This was the first attempt at using a 3D cubic lattice to improve bounciness. It was very dense and too hard. It had a wall thickness of 2mm, a tube thickness of 3mm, and a density of 7.5mm. Version 2: This was the second try using the cubic lattice. It produced great results. It was not too dense, bounced very well, and bounced consistently. It had 4mm wall thickness, 4mm tube thickness, and 10mm density. On average, it bounces 3' 9". Version 3: The third attempt yielded worse results than the previous one. It bounced less, (averaging 3' 4") and less consistently. It had a 3mm wall thickness, a 3mm tube thickness, and a 18mm density. Print Settings Rafts: Yes Supports: Yes Resolution: .2-.4 Infill: 4 shells Notes: If you want to make your own, I suggest you print Version 2. I heavily recommend printing with a raft and minor supports in order to hold up the print since it has no flat surface. Future Expansion and Applications Upon further investigation, I found that there is a fundamental limit to how "consistently bouncy" a 3D printed structure can be. This is a result of 3D printed flexible materials being more elastic in parallel with the layer lines. This results in the ball bouncing best when it's layers are parallel with the surface it is bouncing off of. Paradoxically, 3D printing is the only manufacturing technology that can make this geometry, making this limit unavoidable. This knowledge, along with the designs and information of the project itself could have many applications in controlled compliancy and metamaterials. If the density of the lattice were to be different throughout a 3D object, the finished print would have varying compliancy, i.e., different levels of softness. This is a vital function to mechanical metamaterials. Most compliant metamaterials are based on 2-dimensional structures. This is great for mimicking simple and linear mechanisms, but is not as suitable for more complex systems. A 3D metamaterial structure could potentially solve this bottleneck. Although this is mostly hypothetical right now, I am researching the concept.

With this file you will be able to print NinjaFlex Bouncy Balls with Internal Lattice with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on NinjaFlex Bouncy Balls with Internal Lattice.