Nipper Gripper Repair

thingiverse

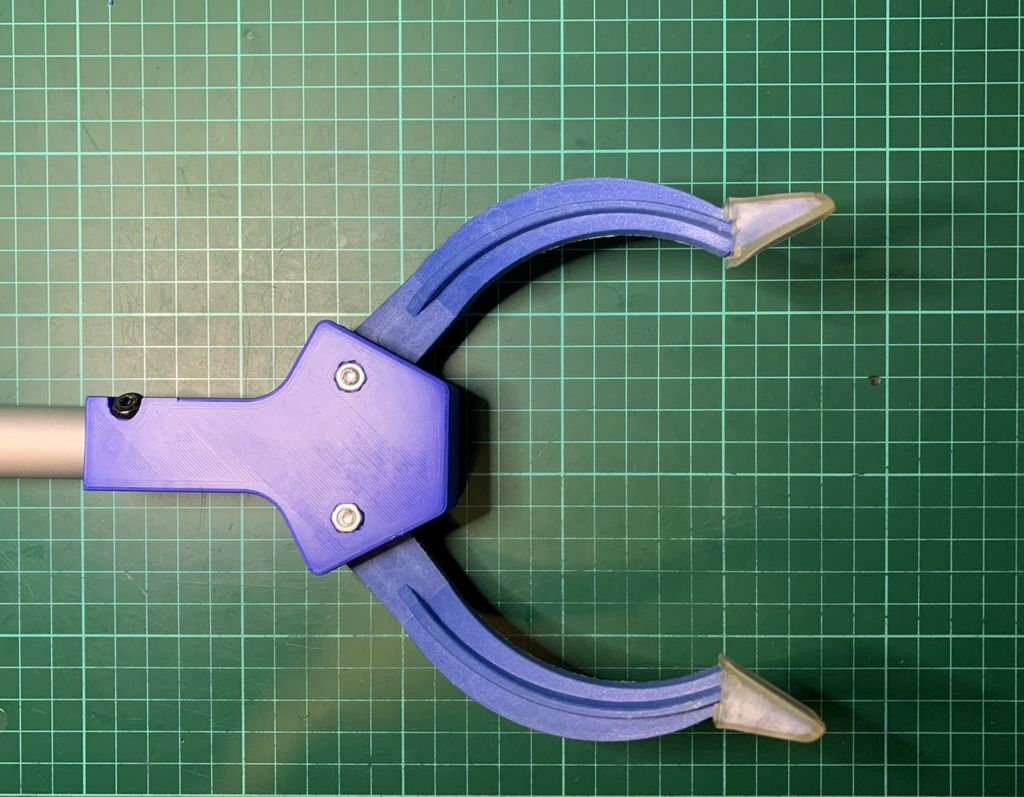

My Oates Nipper Gripper started to show areas of failure. A part at the top had visible cracks and the claws were no longer meeting. Effectively, the gripper was mostly unusable. When working, the gripper served the purpose of reaching distant leaves when I was up a ladder clearing the gutters. The 1 metre length gave me the extra reach I needed. Most of the gripper assembly parts were still in good condition. I identified 3 parts that needed replacing, the cracked top part near the handle and the box surrounding the claws (2 parts). By bringing the claws slightly closer in the box, I would slightly increase the mechanical advantage and need even less handle movement for the claws to meet. The parts will be made in PETG for weather resistance and solid infill for added strength. Here are my 3D designed parts. The shaft is 22mm (OD) aluminium tubing to give a working length of 1 metre. The inside metal strip is steel and about 10mm wide with a cut-out (see photo) for the claws. Functionally, the gripper movement gets a movement mechanical advantage. A 10mm movement in the steel strip translates to about a 150mm movement of the claw jaws. Quite a neat design! My print is made in PETG 1.75mm 3DFillies Blue filament, with 0.2mm layer height and 100% infill on a PRUSA I3 MK3S printer. I hope that you can find this print useful, too. Remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

With this file you will be able to print Nipper Gripper Repair with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nipper Gripper Repair.