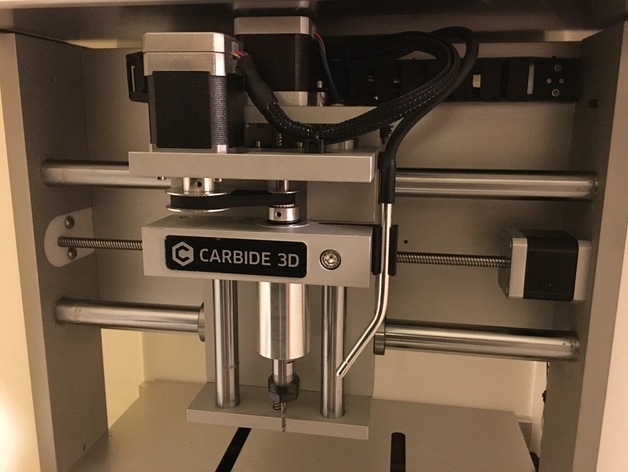

Nomad 883 Pro Air Mod

thingiverse

The idea originally posted by Danny Harper for the SO3 Modified for the Nomad, the Air-Holder is a simple tube grip which holds the custom air nozzle and mounts to the existing Nomad spindle clamp. Learn the process of creating cool, high-tech projects in my micro-fab lab! *If you would like to support the videos, please visit: http://www.diy.engineering/sponsor Parts I Used for this mod: Air-Pump:Apollo Horticulture 35 Watt 40-LPM Commercial Air Pump with 6 Outlet Plastic Divider (Although I tested pumps with volume up-to 3200 GPH, back pressure from the 1/4" tube negated most benefits making this pump fine for most cases. also considering the feeds, speeds and chip size of the nomad 883) Air Nozzle:Campbell Hausfeld MP5143 Pistol Grip Blowgun Hose:Lee's Sleek Airline Tubing, 8-Foot, Black Steps: 1) 3d print the Air-Holder part 2) remove back and top panel of Nomad 883 (remove 9x 3 mm cap head screws + 2x 6 mm button screws, remove back, raise front door and slide top out back) 3) remove press-fit aluminum nozzle from pistol grip blow gun. (protect tube with tape, use pliers to twist, then pull straight out carefully) 4) feed tube through drag-chain. start at spindle side. 5) pull excess tubing through electronics access port. (leave ~10" excess tube on the spindle side) 6) lightly zip tie tube to spindle motor wiring at entrance of drag chain. 7) Drill 1/4" hole in back panel at desired location for tube to exit machine. (I used 3/8" and a grommet to protect the tube) 8) install top panel. 9) Run line through back panel hole (feed through grommet if used) 10) install back panel (start with 2x 6 mm button screws at bottom then install 9x 3 mm cap head screws) 11) back to the spindle-side, cut tube slightly longer that the wires going to the spindle motor. (the air nozzle will be able to slide up and down so be sure to give yourself some slack to adjust the air nozzle position.) 12) remove the 6 mm spindle clamp bolt (note torque of bolt for reassembly) 13) I applied neoprene foam to the air-holder to ensure a snug fit without interfering with spindle clamp. 14) install 6 mm spindle clamp bolt (apply noted torque from step 12) 15) heat end of tube and install nozzle into tube (insert 1/2") 16) snap nozzle into air-holder and adjust position and angle of nozzle. 17) confirm clearance in all positions of the spindle, adjust as needed. 18) heat opposite end of air line to install air pump, insert on barbed pump connector. 19) turn on pump prior to milling operations for a nice chip clearing solution. 20) now go thank Danny Harper for the idea!

With this file you will be able to print Nomad 883 Pro Air Mod with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nomad 883 Pro Air Mod.