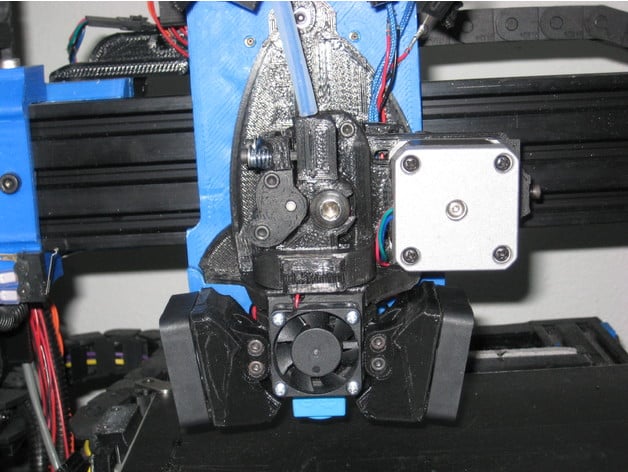

Nova Pro Compact Precision Extruder 2.0

thingiverse

This is version 2.0 of my belted extruder design. The Nova Pro 2.0 extruder is a new lightweight belted design with an extremely short distance between the hobbed section and the hotend. This is an evolution of Belted Wade style extruders, reworked to accept a bondtech dual hobbed gear set, with a flip down idler. it is lighter than a stock Taz 6 extruder by about 30% assuming identical motors, can extrude standard and flexible fillaments interchangably, uses an E3DV6, and the mount plate kind of looks like a rocket! Version 2.0 is a fairly radical departure for extruder design in the bearing department. There is absolutly no need to use 608zz or similar style large bearings here. The 128-27 and 688-2z bearings used are both much smaller, lighter, and will still support thousands of times more load and hundreds of times higher speeds than your typical extruder exerts on them over the life of the bearing.I'd use two of the smaller ones, but the back would need to be a two piece setup. So by making that one slightly bigger, I can still keep it one assembly. Since this is so much changed from the origional one, and none of the origional parts will fit this variant, I figure it is best that it is its own thing. This will print all types of 3.00mm fillament, including flexible fillaments, filled (woodfill etc) fillaments, and every specialty fillament that you can put in a fillament extruder. There is a left hand variant, a Prusa I3 Mk2 mount, and a standard I3 Mk1 rail spacing mount in the works, they won't be done for several days though. I also know the small pulley cover still needs a bit of work. There is a chance that the cable pathway may change a bit too. Once I have time I will be publishing assembly instructions, etc. But for now here are all the main parts if anyone wants to start playing with it. Build Thread https://forum.lulzbot.com/viewtopic.php?f=16&t=5733&p=33503#p33503 Preliminary Bill of materials: 1 Bondtech Drive gear kit for 3.00mm fillament $50 - (Closer to $80 with international shipping) http://shop.bondtech.se/ec/drivegears/drivegear-kit-28530.html 1 128-2Z 8mm shaft 12mm OD 3.5mm wide Stainless Steel bearing -Mcmaster Carr part 7804K115 $7.21 https://www.mcmaster.com/#7804k115/=16na65k 1 688-2Z 8 16 5 Stainless Steel bearing -Mcmaster Carr part 7804K117 $6.13 https://www.mcmaster.com/#7804k117/=16na5vp 1 Gates 2MR88 belt SDP/SI part number A_6R51M088060 $4.82 http://shop.sdp-si.com/catalog/product/?id=A_6R51M088060 1 2mm GT2 65 tooth pulley with brass insert for 8mm bore Polycarbonate for 6mm wide belt SDP Part number A 6Z51M065DF0608 $8.69 http://shop.sdp-si.com/catalog/product/?id=A_6Z51M065DF0608 1 2mm GT2,36 Tooth pulley with brass insert for 5mm Bore Polycarbonate for 6mm wide belt SDP Part number A 6Z51M036DF0605 $6.33 http://shop.sdp-si.com/catalog/product/?id=A_6Z51M036DF0605 2x 8mm shim $0.25 ea Openbuilds http://openbuildspartstore.com/8mm-shim/ 1 8mm dia Stainless Cap head bolt 50mm long - Locally sourced (or whatever 8mm bolt you want to use here) 2x 20mm long M3 bolts for idler 2x 18mm long M3 bolts to hold the lower fan mount on a dozen M3 heat set inserts, half a dozen assorted as yet uncatalouged M3 bolts frm 6mm long to 12mm long shafts, 2x 24v 40mm fans, 1x 5v 30mm fan, an E3Dv6, 6 M3 nuts (2 for idler arm 4 for hotend mount ) 2x idler arm springs from a wade style extruder (not sure what part number for these, I just used ones off an existing extruder 4x M3 washers 1x This or similar Ring E3Dv6 mount https://www.amazon.com/SODIAL-Circular-Aluminum-Reprap-Printer/dp/B0154KD1UQ $3.68 wire ends and fittings for your particular 3d printer setup small zip ties half height NEMA 17 motor 1/4lb ABS plastic Small pulley in testing: http://openbuildspartstore.com/gt2-2m-timing-pulley-30-tooth/ Update 1: All the "ID plates" are now updated. if you want one thats not shown, let me know. The rear belt cover is now ready for use. I have enough cabling through the thing to know that everything is going to fit, and to know that the stock short E3Dv6 thermistor lead has the connector in the worst possible place, so may need to work around that. the old style ones had much longer wires. I3 and I3 Mk2 mounts are underway, the I3 Mk2 mount in particular is proving to be complex. Also uploaded more pictures and a comparison shot of it sitting on my Taz next to my current E3D Taz 6-ish extruder. Note that the entire extruder body of the Nova pro is about the same size as the wade style idler. Video and print sample pictures are coming, I need to fix the thermistor issue and get some time on it, then we'll tear it apart, do a build document, and post more pictures than anyone could possibly ever need. Update 2, the aluminum pulley is working well, and I like that it is small enough to pass the motor into place with the pulley mounted. It does leave the belt a bit long. Still within the adjustment range of the mount, but I am going to try an A 6R51M079030 belt as well to see if it fits a bit better. My goal is to be able to shave a few mm off the adjustment mount. I'll also be uploading a new back cable routing duct thingy to accomodate the needlessly large plug of thenew style E3dv6 cartridge thermistors since they apperently don't make one with longer leads. Look for that soon. There will also be another variant of the mount plate with a slightly deeper cable trench to get more separation behind the belt to avoid any potential wire cutting. Print Settings Printer Brand: LulzBot Printer: TAZ 5 Rafts: No Supports: No Resolution: 0.5mm nozzle Infill: 85% or better infil Notes: The pieces that need support have it built in. The fan shrouds have an integral support layer that is designed for removal, along with the main body. everything else should be fine to print without it. Post-Printing Instructions More complete instructions are on the way. for now, here are some assembly tips. The bolt setup requires some finesse to get in place. you put the front bearing in the case, slide the bolt in, slide the bondtech 8.00mm hobbed gear thing down until it lines up with the feed hole, then insert the back bearing. You should grind a flat spot on the bolt for the hobbed gear and the back pulley setscrew. The other half of the hobbed setup should spin freely in the idler housing. The lower fan shroud may be a tight fit with the cables in place. I'm working on a revised variant that may assemble easier. for now though it seems to work well. esteps is all kind of up in the air at the moment. it should theoretically be around 510 steps, but the small pulley choice may impact that, so you will want to run a calibraton.

With this file you will be able to print Nova Pro Compact Precision Extruder 2.0 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nova Pro Compact Precision Extruder 2.0.