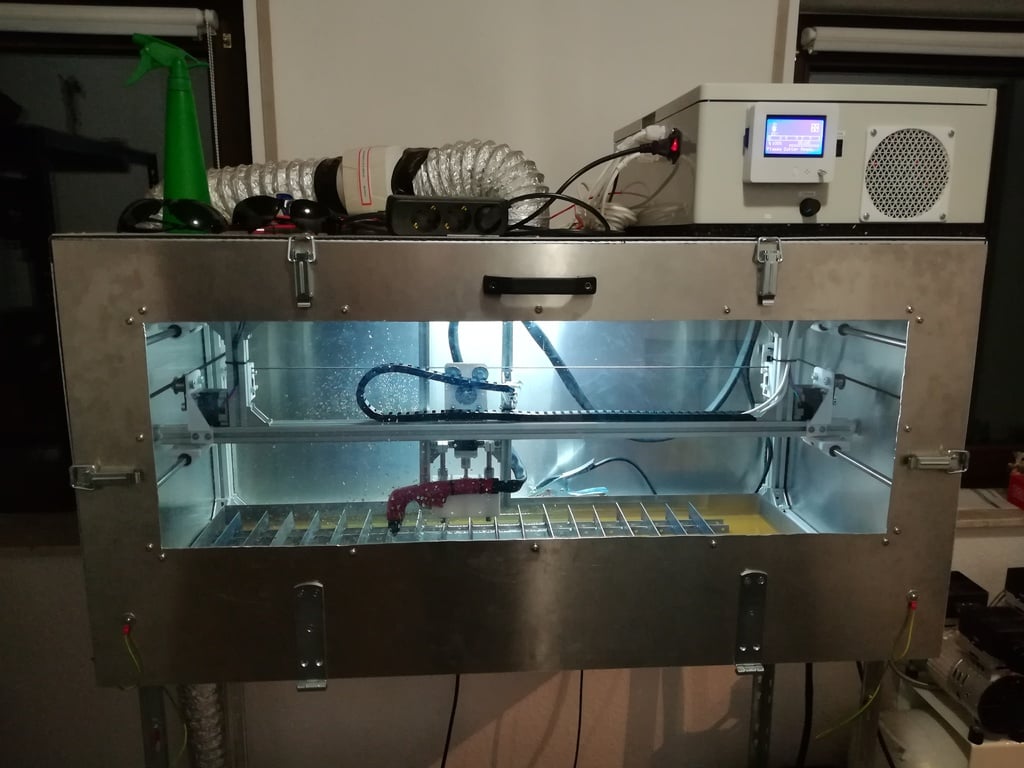

Office Plasma Cutter

thingiverse

This is a CNC plasma cutter in an aluminium box for safely cutting metal next to your 3D printer. I use it for cutting metal parts in my office. It is vented and has an enclosure so sparks and fumes will be kept inside. - Build volume ca 750x350x10 - Ventilated housing to keep the cutting sparks inside and direct the fumes outside - Powered by RAMPS 1.4 with Marlin Firmware - 24V - All parts from Amazon, Ebay and local Hardware Store BOM: Frame: - 4x 1200mm 3030 aluminium profile - 8x 540mm 3030 aluminium profile - 16x 3030 corner brackets - 3030 x M5 T-nuts - M3x20mm screws - M5x20mm countersunk screws - M5x10mm screws - M5x12mm screws - M3 nuts - M5 nuts - washer 5,3x20x1,5 mm - 1x aluminium sheet metal 1200x600x5 - 3x aluminium sheet metal 1200x600x2 - 2x aluminium sheet metal 600x600x2 - 1x polycarbonate sheet 1100x400x3 - 2x hinge - 4x flap closure - 1x spigot Ø100 for exhaust air hose - 1x aluminum exhaust hose 6m - 4x ventilation grilles 70x70 - .>18,42m chimney sealing cord flat 30mm - 1,5mm² yellow/green grounding cable to connect all aluminium surfaces to each other and to the ground - cable lugs - 1x rubber mat 500x400 - 1x fitting 1 1/2" 90° - 1x fitting 1 1/2" double brass - 3030 x M5 sliding blocks - 1x 120mm plastic handle Y Axis: - 4x 590mm Ø12mm linear rod - 8x SK12 linear rod holder - 8x LM12UU - 2x 180mm 3030 aluminium profile - 2x 1190mm 3030 aluminium profile - 6x 3030 corner brackets - 3030 x M5 T-nuts - M5x10mm screws - M5x20mm screws - M4x20mm screws - M4 nuts - M5 nuts - 2x Nema 23 stepper motor - 2x GT2 10mm belt - 2x pulley 20T 6.35mm bore GT2 - cable drag chain 15x30mm - M8x30mm screws - M8 nuts - washer 8,4x16mm - washer 8,4x30mm - 8x Bearing 608 ZZ 8x22x7 mm X Axis: - 2x SBR12 rail 1000mm - 4x SBR12UU - M4x10 screws - 4x 130mm 2020 aluminium profile - 2x 400mm 2020 aluminium profile - 1x 90mm 2020 aluminium profile - 10x 2020 corner brackets - 2020 x M5 T-nuts - 3030 x M5 T-nuts - M5x8mm screws - M5x10mm screws - M5x20mm screws - M4x20mm screws - M4 nuts - M5 nuts - 1x Nema 23 stepper motor - 1x GT2 10mm belt - 1x pulley 20T 6.35mm bore GT2 - cable drag chain 10x20mm - M8x30mm screws - M8 nuts - washer 8,4x16mm - washer 8,4x30mm - 8x Bearing 608 ZZ 8x22x7 mm Z Axis: - 4x SK10 linear rod holder - 2x Ø10mm linear rod - 1x T8 leadscrew - 1x T8 nut - 1x 5mm to 8mm motor jaw shaft coupler - 2x LMH10UU - M5x10mm screws - 2020 x M5 T-nuts - Nema 17 stepper motor - M3x10mm screws - M3x20mm screws - M4x20mm screws - M3 nuts - M4 nuts Water Table: - 1x stainless steel tub 1100x450x70mm - 19x galvanized sheet metal 400x50x2mm - 2x galvanized U-profile 1,5x35,5x1000mm Electronics: - Display Case: https://www.thingiverse.com/thing:87250 - Fan Grill: https://www.thingiverse.com/thing:2802474 - case 500x400x175mm - IEC socket with fuse and switch - LED lamp 12-80V - ReprapDiscount Full Graphic Smart Controller - RAMPS 1.4 - 12V 6A Ø100 fan for exhaust air hose - 3x 12V 120mm fan - switch (enable/disable plasma trigger) - 2x WAGO 221-413 (for connecting the 12V 6A fan) - 4x WAGO 222-415 - 3x stepper driver Nema 23 - 1x stepper driver Nema 17 (for optional THC) - relais module - motor speed controller DC 9-50V 40A 2000W PWM - power supply 24V 20A - 2x DC DC converter 4,5-30V 12A (one for 12V 6A fan and one for RAMPS 1.4) - wiring channel - (optional) thermristor to show room temperature on display - labeling zip ties - normal zip ties - labeling machine (optional) - wire ferrules - cable lugs - cables 4x0,75mm² for stepper motors - cables 2x0,75mm² for plasma trigger - cables 1,5mm² brown, blue, yellow/green for AC wiring - cables 1,5mm² yellow/green for connecting the frame to ground - cables 1,5mm² red, black for DC wiring - standard stepper motor cable for connecting GND, EN, STEP, DIR to stepper motor driver - jumper wires to connect GND to EN-, DIR-, STEP- on stepper drivers - jumper wires to connect the relais module to RAMPS 1.4 - USB cable for programming RAMPS 1.4 You also need: - air compressor - plasma cutter (it´s important to use one with pilot arc because HF - Start can disturb the electronics) - window or good ventilation - fire extinguisher for safety if something goes wrong - towel if water leaks - safety glasses for welding/plasma cutting Setup: - I´ve uploaded my Marlin Setup. Upload it to your RAMPS 1.4 / Arduino Mega via the Arduino IDE and it should work. Operation: - For creating the drawings for cutting you can use Inkscape and Fusion 360 - For creating the cutting paths you can use Estlcam - In Estlcam you can save the paths as .gcode file on your pc or SD card - Then you can insert the SD card in the ReprapDiscount Full Graphic Smart Controller or control your RAMPS 1.4 board using your favorite slicer program - Move your plasma cutter to your desired start point and select on the ReprapDiscount Full Graphic Smart Controller prepare > set origin or send G92 X0 Y0 Z0 via your slicer software - Make sure the compressor and plasma cutter is running, the right amps setting is set, the ventilation is running and the plasma trigger switch is on - start your file - enjoy It is recommended to keep the door open when not in use to prevent the formation of moisture and possibly hydrogen when cutting aluminum https://youtu.be/VfcpGsx3_40

With this file you will be able to print Office Plasma Cutter with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Office Plasma Cutter.