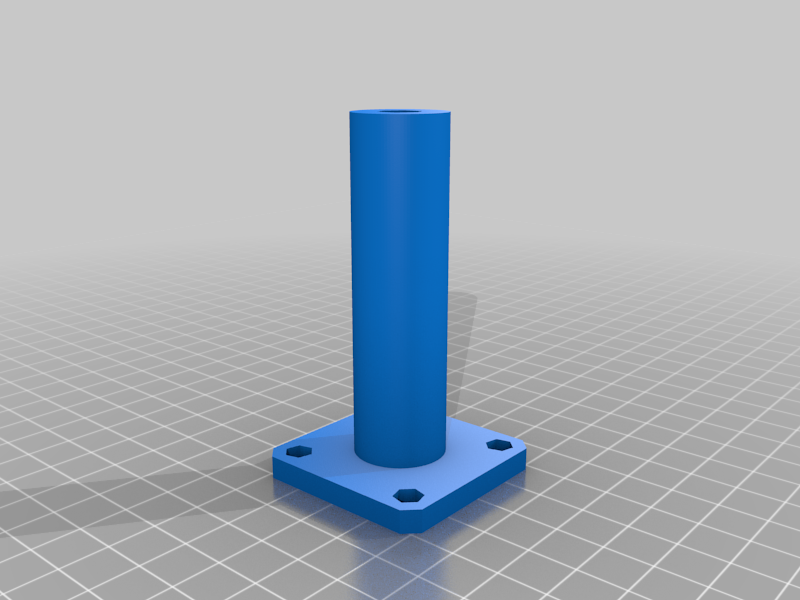

OpenVent - 3D printable BVM Ventilator, Design A2, BLDC motor mount

thingiverse

During the Corona (COVID-19) pandemic it became obvious that a lack of medical equipment can cause a severe impact. Often, also simple equipment and designs can be helpful as long as no professional equipment is available. This repository contains generic information about <strong>an open-source ventilator device</strong>. Main purpose of this project is to build a ventilator when no professional and medical equipment is available. Easy to assemble and available components are used with a clear focus on simplicity, availability and scalability. This project started as part of the <strong>#WirvsVirus Hackathon of the German government</strong> and is intensively being worked on since, including exchange with medical experts. The work is also a selected project in the <strong>give-a-breath-challenge </strong> and <strong>The Global Hack</strong>. <em>Please check the full disclaimer as well before proceeding:</em> The material and documentation here is provided with no warranties explicit or implied. No material on this site is intended to provide medical advice. All designs are intended for investigational use only. This site does not represent any official policies or procedures. The project is provided "as is", without warranty of any kind, express or implied, including but not limited to the warranties of merchantability, fitness for a particular purpose and noninfringement. In no event shall the authors or copyright holders be liable for any claim, damages or other liability, whether in an action of contract, tort or otherwise, arising from, out of or in connection with the software or the use or other dealings in the software. Only use this repository, designs, documentation or any provided information if you accept the above disclaimer. Additional discussion, documentation, source code, electronics and sensor design is available at <strong>GitHub</strong>(https://github.com/mhollfelder/openvent) and <strong>YouTube</strong>(https://www.youtube.com/channel/UCw9h6QsYEKY2sfZIYBNuHvw) and <strong>DevPost</strong>(https://devpost.com/software/openvent-open-source-3d-printable-ventilator). This thing represents a further extension / variant based on our evolved design A1. Further extensions and upgrades will be posted here as well. Please check those, too. <strong>General concept</strong> An AMBU-bag is used as pressure reservoir. It already features an O2 inlet (O2 concentration is crucial for patients with acute respiratory syndrome) and several safety features including e.g. overpressure and bypass valves. Being standard for emergency help, these bags are available at substantial volumes. A motorized and microcontroller+sensor controlled setup squeezes the bag at the right pattern, supporting assist-, pressure-, volume- and flow-control ventilation and exhaled gas measurements and filters. Our Implementation is based on hardware compatible to Arduino, an #Infineon <em>XMC4700 Relax Kit</EM> and a <em>Stepper Motor Control Shield</em> with IFX9201 and XMC1300 on it. Among other sensors, two pressure sensors DPS368 are used for differential pressure detection. The user interface includes a commonly available I2C LCD Display Module 128 x 64 Pixel for Arduino. All is based on open source and commonly accessible parts; especially for the mechanics the objective is to be scaleable in production and hence fully 3D-printable. Only the motor and it's screws as well the belt is not printed. Standard stepper motors such as Nema-23 are proposed. Electronics, sensors and software are covered in our GitHub pages. <strong>Improvements</strong> Based on the positive experience and confirmation of robustness with the already evolved A1 design, we aimed at improving the actual usability even further, specifically removing or hiding the belts/ropes across the ambu bag as they could potentially become a source of error in practical daily use. At the same time, the objective was, to not increase the required build volume and also to keep print time/volume within bounds. The presented design covers both and a really solid frame to hold the bag and keep it from moving around as an additional benefit. The optimal height of the punch block is yet to be confirmed. The actual design can easily be scaled vertically to experiment with different sizes. <strong>Experiences</strong> This design has proven to be extremely robust, whilst still simple in design. The increase in print-complexity vs. the initial A0 design is moderate and slightly reduced vs. the A1 design. On standard printers with little less than 20cmx20cm build area this would typically require two sequential print jobs. Still it can be done in less than 18 hours at 0.25mm layer resolution (350g). Robustness has higher priority than printing time. However, such high resolution is not required for the design, hence additional speed-up potential is given. While this design enablers 'smaller' motor variants such as a Nema-17, these can become very warm under (rather theoretical) continuous maximum load, and thus the rotor should be printed from high temperature PLA/material. Nema-23 appears to be the preferred choice. More detailed discussions on our GitHub pages.

With this file you will be able to print OpenVent - 3D printable BVM Ventilator, Design A2, BLDC motor mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on OpenVent - 3D printable BVM Ventilator, Design A2, BLDC motor mount.