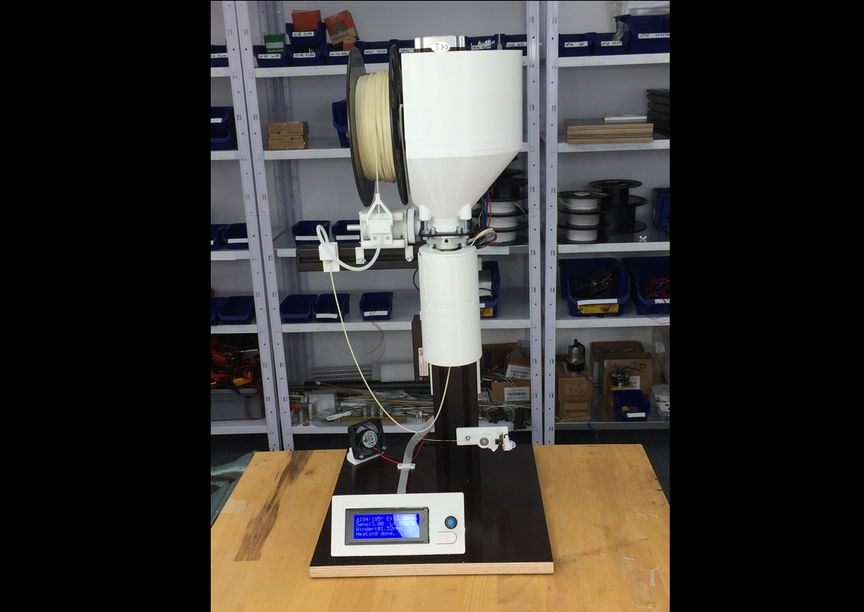

Original Desktop Filament Extruder E1.5 by ARTME 3D

thingiverse

<iframe width="560" height="315" src="https://www.youtube.com/embed/6-vFJSqzzM0" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe> I update the 3D print files and documentation regularly. If you want to download the project, please do it here: https://artme-3d.de/support. The original desktop filament extruder E1.5 from ARTME 3D has developed in great strides. It is a plastic extruder in an unbeatably small but powerful design to produce filament for 3D printers from plastic granulate. Thanks to the well thought-out design and the arrangement of the components, self-made (shredded) granulates, e.g. from 3D printing waste, can also be processed well. The original desktop filament extruder E1.5 from ARTME 3D is an open source project which is used under a CC BY-SA license (https://creativecommons.org/licenses/by-sa/4.0/). I sell this Extruder as a DIY KIT: https://artme-3d.de. The development and documentation of this project required hundreds of hours of work in 2.5 years, as well as high investments in materials and machines. If you would like to support me in the development of further projects, I am looking forward to a small donation via paypal to paypal@artme.de. The extruder works with an extruder screw with a compression zone made of stainless steel and has a winding unit to wind the filament directly onto a spool. And that with a footprint of just 30 x 35 cm. The drive consists of a powerful andvariable Nema23 stepper motor with planetary gear, which is controlled by a digital stepper motor driver. The take-up unit is driven by a Nema17 stepper motor with planetary gear. An Arduino with a ramp board and LCD display takes over the control. The winding works automatically. After the adjustable filament length, the extruder switches off automatically. The extruder easily processes the standard 3D printing materials such as PLA, ABS, ASA, PETG, TPE into filament. However, this version does not yet process high-temperature plastics such as nylon reliably due to the geometry of the extruder screw. The extruder is operated with 12V safety extra-low voltage and due to its high efficiency it requires little power, so that it can be operated, for example, with an inexpensive and safe desktop power supply. (Not included in the delivery). Climate-neutral operation using solar cells is also possible. The complete documentation and the necessary 3D print files can be found here: www.artme-3d.de/support The extruder was developed under the following aspects: Miniature design to enable decentralized use wherever plastic can be recycled or filament should be produced cheaply. Short lead times in order to damage the plastic as little as possible, in order to enable many recycling processes. Open source to give everyone access to successful recycling. Process stability through high quality and well thought-out components. Comfortable control and easy operation. Easy and quick adjustment of the filament diameter. Inexpensive to buy as it can be bought as a kit. Technical specifications: Dimensions: 300mm wide, 594mm high, 350mm deep Power supply: 12V DC protective low voltage Power consumption: 45 to 70 watts (depending on the type of material), 80 watts when heating up. (Required power supply unit for mains operation: output voltage 12VDC, output current 7 to 10 A) Maximum extruder temperature: 250 ° C Maximum speed: 20 RPM Filament diameter accuracy: +/- 0.05mm. Maximum extrusion performance without filament calibration: 350 grams per hour Normal extrusion line with filament calibration: 100 to 200 grams per hour Maximum system speed (dimensionally accurate production and winding of filament): 0.5m to 1.2m per minute. Accordingly, it takes on average about 6.2 hours to produce about 750 grams of filament with a 1.75mm diameter. Extruder screw: 3 zone extruder screw made of stainless steel with 12mm diameter. Compression ratio approx. 3: 1. L / D ratio: 10: 1. Tested materials: PLA, ABS, PETG, TPE Functionality: The plastic granulate is melted by the extruder and leaves the nozzle with an integrated melt filter as a soft thread. In order to be able to process shredded materials, the extruder tube has to be modified, which can be done in-house with a round file. The diameter of the filament is set by the weight of the filament itself and the pressure and temperature options. A sensor detects the height of the filament and regulates the winding speed. Due to the small design, the diameter setting is relatively quick. If the appropriate values for the type of plastic are known, the extruder can be started in a few minutes. You can find empirical values for the setting at www.artme-3d.de/support

With this file you will be able to print Original Desktop Filament Extruder E1.5 by ARTME 3D with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Original Desktop Filament Extruder E1.5 by ARTME 3D.