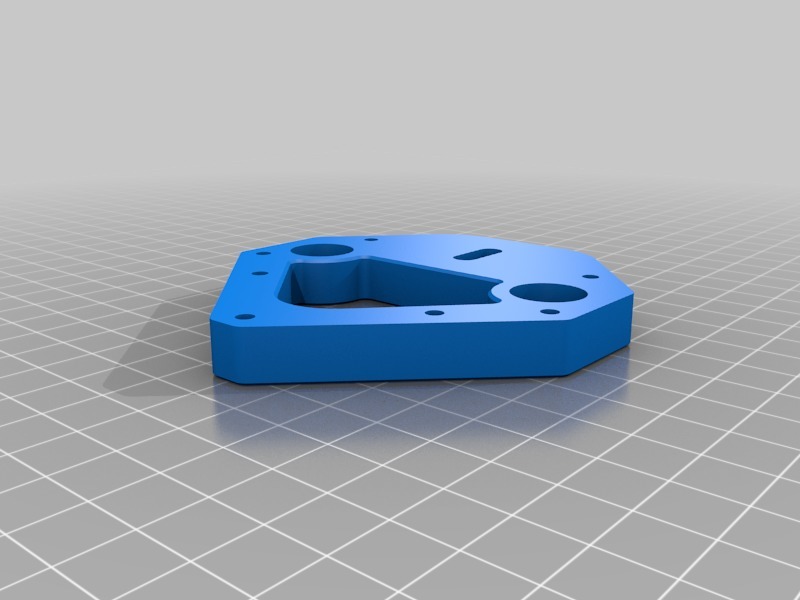

Palatis FricEx (belt driven friction extruder cold-end) (1.75mm filament)

thingiverse

An extruder code-end inspired by Gunstruder (https://www.thingiverse.com/thing:1247952). I basically designed this to avoid griding into the filament. Bill of Material: 1. 172mm (86t) closed-loop GT2 Timing Belt x 1 2. GT2 16T pulley (D13 * 14mm, 5mm bore) x 3 3. NEMA17 stepper motor (5mm shaft) x 1 4. D5 x 25mm shaft x 3 5. F685 (ZZ/2RS) bearing x 4 6. MF105 (ZZ/2RS) bearing x 2 7. M3 square nut x 4 8. sunken head M3 30mm x 3 9. sunken head M3 10mm x 1 10. sunken head M3 25mm x 2 11. M3 20mm x 2 (for pulley tension adjustment, any M3 longer than 20mm will work) 12. 4mm PTFE pipe fitting (M6 threads) x 1 or 2 For mounting the cold-end to 2020 aluminum extrusion, you will need: 1. sunken head M3 30mm x 2 2. M3 T-nut x 2 or duct tape / superglue... Assembly: 1. insert the 2 MF105 into the filament idler pulley 2. insert the 4 F685 into the top / bottom casing 3. Insert the square nuts into the square holes 4. Install the 16t belt pulley on the motor 5. install the 2 16t idler pulley on and the belt, arrange them in a triangular shape 6. screw everything together 7. adjust the tension of filement idler pulley Extruder steps/mm example: ``` stepper steps per revolution * microstepping / (stepper pulley teeth * belt pitch) = 200 (1.8deg) * 16 (microstepping) / (16 (teeth) * 2 (gt2 2mm)) = 100 steps / mm ``` however, always calibrate E-steps/mm for your printer.

With this file you will be able to print Palatis FricEx (belt driven friction extruder cold-end) (1.75mm filament) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Palatis FricEx (belt driven friction extruder cold-end) (1.75mm filament).