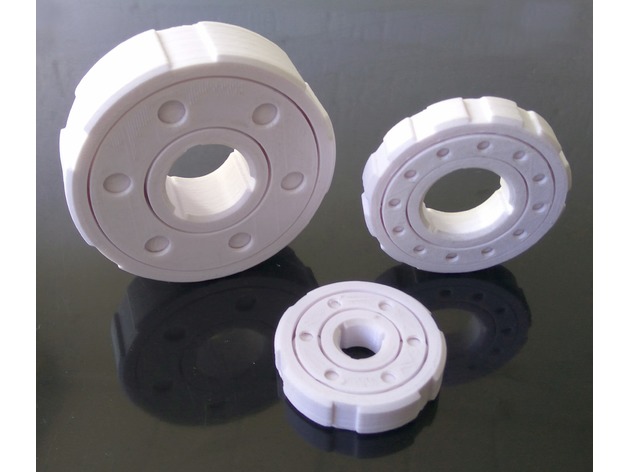

Parametric Caged Ball Bearing

thingiverse

Parametric Caged Ball Bearing This is a customizable parametric ball bearing, that is designed to be printed in a single step. Note: It is extremely challenging to free up the components of this bearing after printing. However, once the components are free, it works great. See the linked video, to get a feel for how various configurations of the bearing perform. Video:https://youtu.be/iAHtHwBg-FU Hint When your hands are bleeding, because you have stabbed your fingers multiple times with the utility knife, and you have friction burns on both hands, ...you are halfway to freeing up the bearing. Maybe the real hint here is that you should wear gloves. Parameter Overview All linear, axial and orthogonal dimensions are measured in millimeters. Angles are measured in degrees. And ratios are normalized to the range, [0.0 .. 1.0]. Model Options Resolution Resolution specifies the tessellation factor of the model. The higher the tessellation factor, the more polygons make up the model. And in turn, the smoother the model. For moving parts like a ball bearing, the smoother the model, the better. So a fairly high resolution of 64 or greater should be selected. I used a resolution of 128 for all the bearings I have printed with this model. Enable Inner Ring Include the inner ring if yes. Else, omit the inner ring from the model. This is mostly used for debugging, visual analysis and testing. Enable Outer Ring Include the outer ring if yes. Else, omit the outer ring from the model. This is mostly used for debugging, visual analysis and testing. Enable Cage Include the bearing cage if yes. Else, omit the bearing cage. Due to the friction induced by the cage, most 3D printable ball bearings may spin more freely without a cage. However, even though a cage introduces more friction, load forces are distributed more evenly to the bearing raceway with a cage, leading to an overall better performing bearing. High volume space filling cages like the one in this design, also serve as a spherical support guide for the balls during printing, which improves the spherical quality of each ball. Enable Balls Include the bal array if yes. Else, omit the balls. This is used for debugging, visual analysis and testing. Enable Inner Ring Chamfer Enable a chamfer on the inner ring if yes. Else, ignore inner ring chamfer parameters. Enable Outer Ring Chamfer Enable a chamfer on the outer ring if yes. Else, outer inner ring chamfer parameters. Enable Inner Ring Knurling Enable knurling cuts on the inner ring if yes. Else, ignore inner ring knurling parameters. Enable Outer Ring Knurling Enable knurling cuts on the outer ring if yes. Else, ignore outer ring knurling parameters. Enable Bottom Cage Access Ports Enable access ports on the side of the cage, that is facing the build plate during printing. Presuming that the bearings are oriented flat on the build plate, then we can call this the bottom face of the cage. Access ports serve a dual purpose. 1.To gain access to the support material used to for the balls, if support material is used. 2. To gain access to the balls themselves after printing, so that they can be manipulated in order to free them from the cage and the rings. Enable Top Cage Access Ports Enable access ports on the side of the cage, that is facing away from the build plate during printing. Presuming that the bearings are oriented flat on the build plate, then we can call this the top face of the cage. It is a good idea to include access ports on both sides of the cage, to maximize access to the balls for post printing manipulation, as well as to ensure balanced rolling in the cage, once the balls have been freed. Ring and Cage Parameters: Bore This is the inner diameter of the inner ring. It is a good idea to make this value slightly larger than the diameter of whatever shaft is intended to pass through the inner ring, by about 0.1mm to 0.5mm. Presuming, that the target shaft diameter can't be adjusted itself. If need be, the Model Options above may be used to print only the inner ring as a test part, that may then be be fitted to the target shaft, in order to iteratively evaluate physical assembly characteristics, without having to print the entire bearing assembly each time. Outer Diameter This is the outer diameter of the outer ring. It is a good idea to make this value slightly smaller than the diameter of whatever bracket assembly the bearing is intended to fit into, by about 0.1mm to 0.5mm. Presuming, that the target assembly dimensions can't be adjusted themselves. If need be, the Model Options above may be used to print only the outer ring as a test part, that may then be be fitted to the target assembly, in order to iteratively evaluate physical assembly characteristics, without having to print the entire bearing assembly each time. Shoulder Height This is the raised boundary edge of the bearing raceway. In general, lower values are prefered. The minimum shoulder height required to give the balls a secure raceway to roll along, should suffice. For bearings whose outer diameters are less than 60mm, a 1mm to 1.5mm shoulder height is usually enough. Radial Gauge This is the thickness of the rings, as measured from the deepest point of the ring raceway, to the inner or outer diameter of the inner and outer rings respectively. Axial Gauge This is the thickness of the ring and cage walls. Cage Access Port Diameter This is the diameter of the cage access ports. In general, the larger the better, especially if support material is going to be used to support the balls above the build plate during printing. Mechanical Properties: Ball Count The number of balls. Ball Ring Clearance The clearance between each ball and the rings. The radius of the balls is reduced by this clearance amount. In general, fairly low clearance values should be used between the balls and the rings, in order to promote grip between the balls and the ring raceways. For most applications, clearance in the range of 0.1mm to 0.3mm, works well for clearance between the balls and the rings. Ball Cage Clearance The clearance between each ball, and its cage cavity surface. The radius of the cage cavity surfaces, are increased from the radius of each ball, by this clearance value. Larger clearance values are suitable for the clearance between the balls and the cage, in order to reduce friction. It is a good idea to set the clearance between the balls and the cage, to a larger clearance value, than the clearance between the balls and the rings, in order to promote frictional contact between the balls and the rings, rather than unnecessary contact between than balls and the cage. In general, a value of two to three times the clearance between the balls and the rings, works well for the clearance between the balls and the cage. Most of the bearings that I print using this model, are configured with a ball to ring clearance of 0.1mm, and a ball to cage clearance of 0.3mm, using a 0.3mm nozzle, and a print resolution of x=0.3mm, y=0.3mm, and z=0.15mm. Feature Parameters: Inner Chamfer Size The radial size of the inner ring chamfer. Outer Chamfer Size The radial size of the outer ring chamfer. Inner Knurling Count The number of equally spaced knurling cuts made into the inner ring. Inner Knurling Depth The depth of the inner knurling cuts. Inner Knurling Cut Ratio The proportion of the knurling arc, that is cut into the ring. The higher the ratio, the more material is cut from the ring. Outer Knurling Count The number of equally spaced knurling cuts made into the outer ring. Outer Knurling Depth The depth of the outer knurling cuts. Outer Knurling Cut Ratio The proportion of the knurling arc, that is cut into the ring. The higher the ratio, the more material is cut from the ring. Color Settings: Color settings are used for debugging and analysis. Enable Multiple Colors Render each class of component in using different colors if yes. Else, render all components in the model using one color. Default Color The color to use if "Enable Multiple Colors" is set to No. If "Enable Multiple Colors" is set to Yes, then "Default Color" is ignored. Inner Ring Color The color to render the inner ring, when "Enable Multiple Colors" is set to Yes. Outer Ring Color The color to render the outer ring, when "Enable Multiple Colors" is set to Yes. Ball Color The color to render the ball array, when "Enable Multiple Colors" is set to Yes. Cage Color The color to render the bearing cage, when "Enable Multiple Colors" is set to Yes. Print Settings Printer Brand: RepRap Printer: RepRap Kossel Rafts: Doesn't Matter Supports: Yes Resolution: x=0.3, y=0.3, z=0.15 Infill: 66% Notes: Because of the number of moving parts and the relatively tight tolerances, it is a good idea to print slow and cool. All the bearings I have printed from this model, have been printed using PLA, at a speed of 6mm/s to 8mm/s, at a temperature of 190 deg. While I have not tried ABS or any other higher temperature/higher viscosity materials, I am going to presume that the same principle of low speed, low temperature will hold. Post-Printing 1. Remove Support Material Remove any support material from the access ports, as shown in the picture below. 2. Free the Inner and Outer Rings Free the rings, so that they can both slide over the balls, even if the balls do not yet move. Usually the inner ring will be easier to free. The outer ring may take quite a bit of manipulation to get free. If a blade is used to manipulate the rings away from the cage and balls, care should be taken not to damage the rings or balls with the blade, as this will impact how smoothly the bearing operates once everything is free. 3. Free the Balls Free the balls, by manipulating them through the cage access ports, using a sharp implement. 4. Wear in the Components How effective this step is, depends on the properties of the material the bearing is printed with. Soften the bearing assembly by submerging it in hot water. For PLA, hot water from the bathroom basin tap should suffice. For ABS, boiling water may be required, and so care should be taken not to burn oneself during this process. In the case of PLA, take the bearing out of the hot water an quickly begin rolling the bearing along a solid surface capable of gripping the bearings outer knurling. A bathroom towel laid down on a hard table top works well. Repeat the process of softening the bearing in hot water and then rapidly rolling it back and forth across the grip surface, as many times as is required to smooth out the mechanical performance of the bearing. Note: For ABS and other materials that require boiling water. Use gloves and be careful not to burn your hands in the boiling water, or on the bearing which will also be pretty hot if it has been submerged in boiling water. 5. Refine Moving Components (Optional) This step is optional, but works really well with PLA. I have not tested the idea with more durable materials. Once the bearing is already spinning a bit, take any household scouring powder product, and smear a generous helping of dry scouring powder into the moving parts of the bearing on both sides. Then drive the bearing back and forth over a high grip surface, like a bath towel on a hard table surface. Rinse out the scouring powder with cold water, and repeat the scouring powder step until the bearing is spinning optimally after rinsing with cold water. How I Designed This

With this file you will be able to print Parametric Caged Ball Bearing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Parametric Caged Ball Bearing.