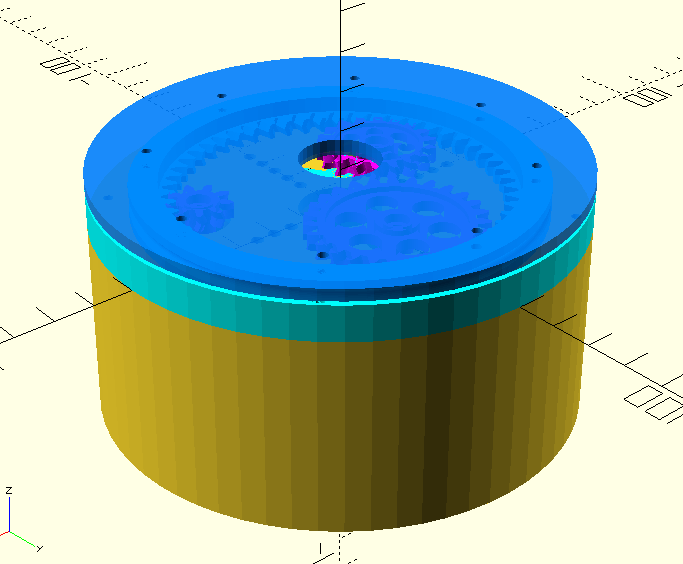

Parametric Turntable (for mg996r servos) with 3 speed gear box.

thingiverse

This is a turntable that offers 3 positions to mount a servo to configure a gear ratio as needed. It has a central hole to pass wires through to the top. It is **extremely** configurable with well documented parameters. The assembled unit feels very sturdy. By design it should handle reasonable radial and axial loads, and be fine with the type of moment loads that come from a small robotic arm. Hardware wise, It requires stainless steel bearing balls, and machine screws to assemble. Some holes for the machine screws require tapping, no bolts are required. The whole this is parametric, so configure mounting options, gear ratios, bearing ball sizes, turntable diameter to meet your needs. It is pre-configured for m3 machine bolts, and 4mm bearing balls. ** Currently this does not load correctly in the thingiverse online customiser. However it works well when used with the OpenSCAD customiser GUI. ** In openscad preview, you can see the servos rendered transparently as well as the bearing balls. This is to see if the servos collide or obscure anything, and to check the bearing ball packing. This geometry is not rendered in the final render (eg: to stl). Configuring: - Configuring the gear ratios moves the servo placement. This may cause the servos to be poorly positioned or collide. The *linear_placement* setting can be toggled if this happens to re-arrange the servos. See the servo_setting.png for more info. - There are lots of settings, but 90% of common settings are in the *structure* section. Printing: - There are 7 parts, assembly as per the animated gif. - Most parts print upside down, no supports are required for any part. - Configured by default for minimal material usage, which is fairly rigid out of the box. Strength can be ramped up as needed in the structure section. - use the *create_?* options to enable one part at a time for export. Export with *rot_steps* set to at least 512. When assembling: - Only install one motor and gear (as per desired gearbox setting) - Place gear, then install servo, you can't do it the other way round. - Lower bearing housing, inner ring, bearing balls, then top bearing housing. - Lubricate bearing balls before use. A flat top platform is provided as a reference (or for simple turntables). It is assumed you have something else in mind for this, the function *platform* is intended as a reference to achieve this. - The top platform mounts to the ring gear via the configurable screw spacing. The holes for mounting are arranged with their centres on in a circle of diameter calculated as: * outer_diameter - mount_hole_recess_from_bearing_edge * This project uses the gear library of Dr Jörg Janssen - https://www.thingiverse.com/thing:1604369 - https://github.com/chrisspen/gears

With this file you will be able to print Parametric Turntable (for mg996r servos) with 3 speed gear box. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Parametric Turntable (for mg996r servos) with 3 speed gear box..