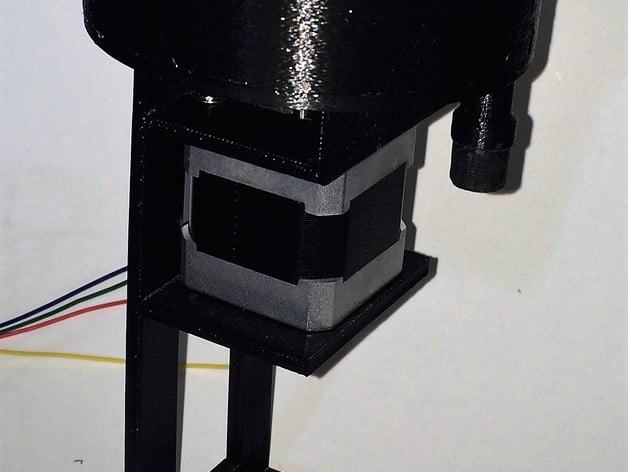

Pellet Dispenser for Operant Chambers

thingiverse

45 mg Pellet Dispenser for Operant Conditioning Chambers. First look at the Operant Conditioning Chamber: http://www.thingiverse.com/thing:1226076 A layer height of 0.2 mm with 20% fill density is recommended. Only the Ring.stl requires support material. I use lines to facilitate removal. It is recommended to print the Pellet_Disk.stl and the Disk_Support on a heated bed. Because the pellet disk rotates on top of the support, a smooth surface on these parts facilitates movement. You will need also the following materials: 1 - Nema 17 stepper motor Model 17HS4401. 1 - Pololu Universal Aluminum Mounting Hub for 5 mm shaft # 4-40 holes 4 – M3 or 4-40 Screws. These screws are used to attach the rotating disk to the holes in the mounting hub. 1 - 4988 Motor controller with 1 - 47 uF or 100 uF capacitor. E6000 glue. The two sections of the stand (support.stl) are glued together. The ring must be glued to the disk support. Also the knob must be glued to the lid (cover.stl). Print Settings Printer Brand: Robo 3D Printer: R1 ABS + PLA Model Rafts: Doesn't Matter Supports: No Resolution: 0.2 mm Infill: 20%

With this file you will be able to print Pellet Dispenser for Operant Chambers with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pellet Dispenser for Operant Chambers.