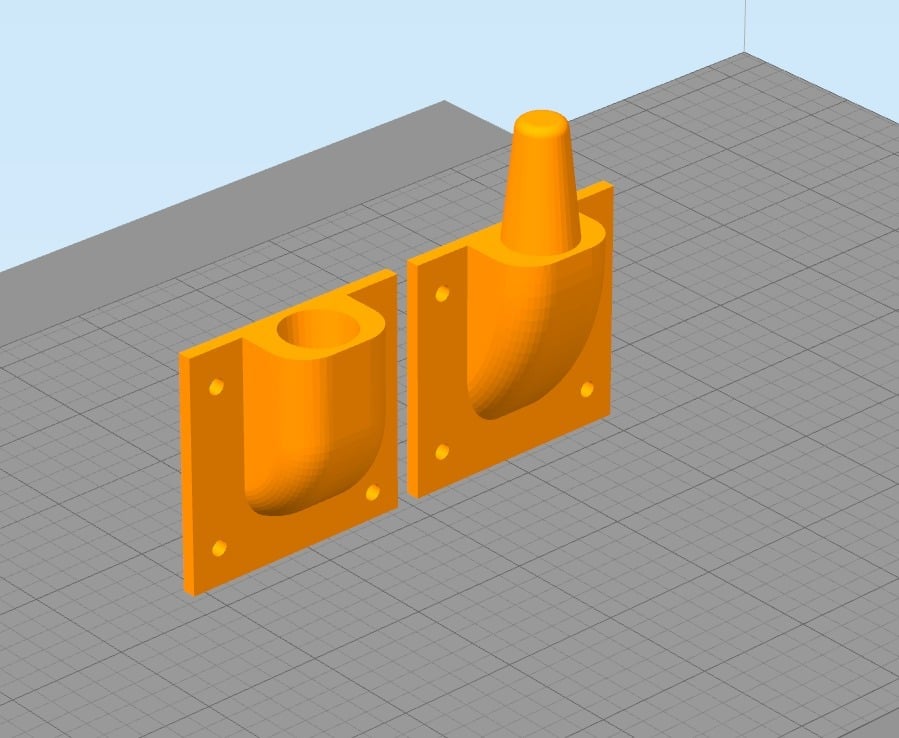

Pergo Cope and Drag Alignment for Sand Casting

thingiverse

When pouring aluminum using green sand, your cope and drag boxes need to be aligned precisely. Attach a set of these to the long sides of each box by screwing them in place. This ensures perfect alignment when assembling the boxes for casting. I found it convenient to print these on their ends with no supports, which resulted in a gradual increase in width as you move up the model due to the filet on the parts. I printed this in PLA. The Solidworks 2016 source files are included for anyone who wants to modify them for smaller jewelry boxes or larger engine blocks. My mirror prints often crack due to its cracked surface, but it remains functional atop my NeoCeram bed as long as it doesn't move and stays flat when rubbed with fingers. I have four more 10x15-inch mirrors on order to replace it once it stops working properly. Mirrors from Home Depot or Lowes usually don't crack until they reach around 83 degrees Celsius, but I print PLA at 70 degrees Celsius and ABS at 80 degrees Celsius.

With this file you will be able to print Pergo Cope and Drag Alignment for Sand Casting with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pergo Cope and Drag Alignment for Sand Casting.