Pergo Robo3D Pillow Blocks For Aluminum Casting

thingiverse

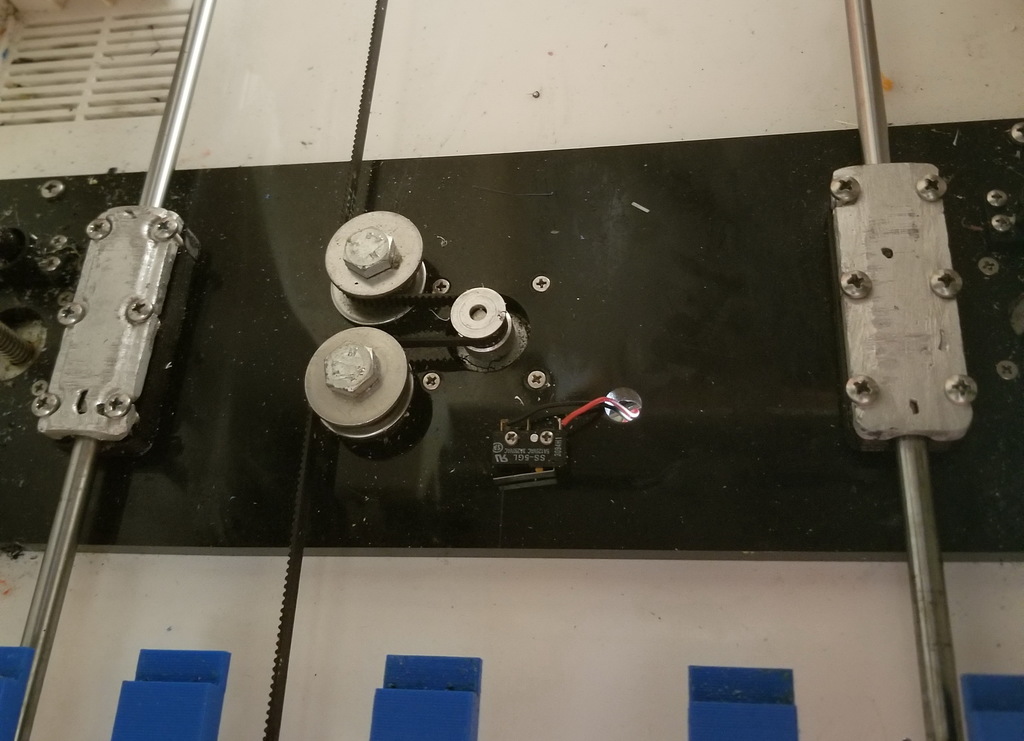

I've printed about 3 sets of these darn pillow blocks. With a longer bed there is more stress on the pillow blocks... https://www.thingiverse.com/thing:2216671 .. OR.. I'm just cranking too hard on the individual screws/nuts so over time the top block cracks and I end up with a wobble in my Y axis. Well NO more! I created this mold that you print and fill with either plaster of Paris or 50/50 plaster of Paris and playground sand. I've done both ways, poured and cast in 30 mins, and waited 3 days. Each yields similar great results. I did notice two different things though: If I use charcoal for the foundry, the part comes out perfect size (same as the correct sized mold). If I use a propane foundry, I get some shrinkage (about 4.5 mm in the long axis) So if you can get your aluminium really hot! then you need resize the print about 4.5 mm taller. (103.79%) Yes I printed with a .4 mm nozzle and .3 Layer Height You can see that while my castings are installed in the printer they are far from perfect but good- golly they work REALLY well. I really didn't expect that thin aluminium was so strong. There are also two different models in my printer but the only one I'm sharing is the best one. The one on the left, the one with the recessed screws. Due to the superior strength of the castings, we don't need the thickness that the original injection molded ones had. also found that you only need the tops as the majority of the stress is there. My bottoms are still plastic 3D printed. If you have Solidworks I recommend the idea I used here where you create your model and just print a box around with the assembly and join. Print it, fill with plaster, let harden, burn out the PLA at full strength of your foundry. this is why I allow the bottom hole in the model. The PLA leaks out either from the top or the bottom depending in how you put it in your foundry. blow out with air compressor. BE SURE YOU USE safety gear. Bury it in your sand, (this caps the bottom hole) and pour in the aluminum.

With this file you will be able to print Pergo Robo3D Pillow Blocks For Aluminum Casting with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pergo Robo3D Pillow Blocks For Aluminum Casting.