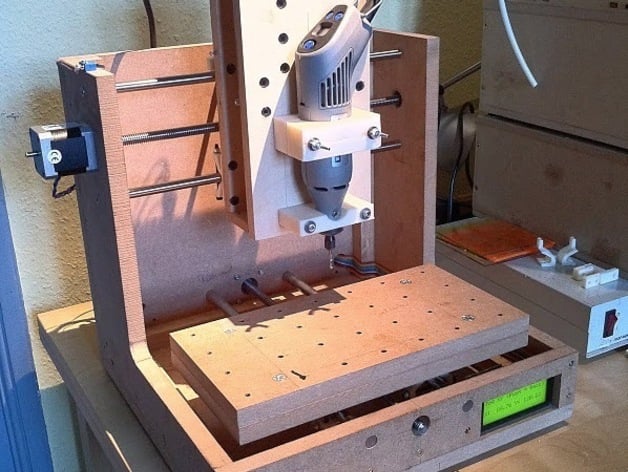

Pleasant Mill v1

thingiverse

This is a DIY CNC mill. The z axis is kind of universal. Mine currently makes use of http://www.thingiverse.com/thing:8481 to attach a Dremel as spindle, but using other tools or even an extruder shouldn't be a problem. This thing contains only the (mostly wooden) mechanical construction of the mill. Electronics and software are not included. I use custom made electronics and software with mine, but both aren't ready for publishing yet. You might use a RAMPS board or even Makerbot PCBs to drive this mill. For more information on the Pleasant Mill project, seehttp://pleasantsoftware.com/developer/3d/2011/05/13/poor-mens-laser-cutter/ [Update] I already stated this in the above blog post, but since there was a complaint in the comments, I'd like to add attribution to David Carr (http://makeyourbot.org/mantis9-1) also here. He designed the Mantis Mill, which the Pleasant Mill's design is based on. However, I designed my own Z axis, use linear ball bearings, different (and metric) dimensions and a bunch of other design changes and additions. See above link for more info.[/Update] Additional pictures are available here:https://picasaweb.google.com/ZaggoPS/PleasantMill?feat=directlink Instructions The design is for 16mm MDF or plywood. I used MDF because it is usually very flat, which might be a problem with plywood, which tends to warp. The disadvantage of MDF is, that you can't put screws directly in the face side (it's too soft). Therefor you want to use either additional wood profiles in the corners (which is what I did), or some other way to securely connect the parts (e.g. cross nuts). Since there was no room for extra wood profiles, I used plywood for the x-axis. That way I was able to directly screw the z-axis upper and lower parts to the x-axis sheet. Again, another way to solve the problem would be the use of cross nuts. If not stated otherwise, all holes have a diameter of 4 mm. You also need: 3 NEMA 17 Stepper motors (e.g. SY42STH47-1684B) ACME threaded rods (e.g. TR10x2mm): 2x 300mm, 1x 220mm ACME nuts Precision rods (e.g. from old printers or scanners, preferable 10 or 12mm diameter): 2x 360mm, 2x 352mm and 2x 250mm Lots of M4 bolts, nuts and washers, some M3 bolts for the stepper motors Some kind of controller board, e.g. RAMPS or any other solution, able to drive 3 stepper motors http://www.thingiverse.com/thing:8480 http://www.thingiverse.com/thing:8481 The ACME nut retainer below is for ACME nuts with OD 22mm (TR nut 10x2 / 22x20)

With this file you will be able to print Pleasant Mill v1 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pleasant Mill v1.