Pocket Printer Upgrade - hybrid roller slides

thingiverse

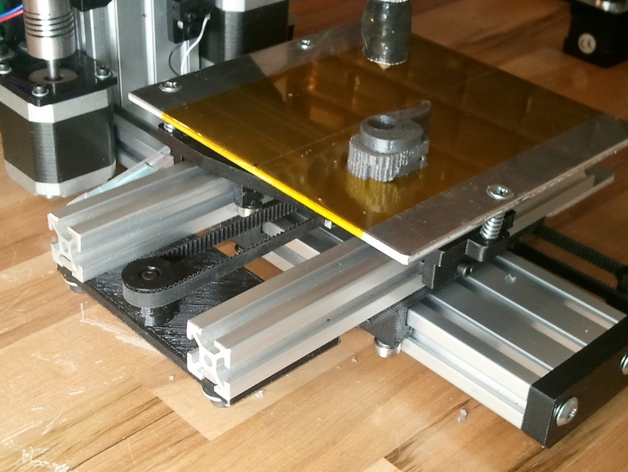

This printer won't quite fit in your pocket, but it is very easy to take with you. I designed the printer around two constraints. First, the high mass motors and extruder are stationary. This allows smooth high speed printing, as only the print bed moves. This keeps the forces on the slides low as well. This will also allow dual extruders on a very lightweight printer. Second, the slides are all integrated, using PLA bearing surfaces running on the extrusions. I wanted to try this on all the axes of a printer since it works so well on my Aluminum Mendel. It is self-contained, with power supply on board. It is very robust, and makes top quality prints. I made this printer to test the above constraints, but it works so well I decided to publish it. The print volume is 120mm W x 100mm D x 65mm H. This could be expanded a little by getting longer extrusions. Pocket Printer on Marlin - http://youtu.be/lAwCmbKS-yQ I have comb activated, so it travels around the cord cutout on this iPhone dock at a very rapid travel speed. Watch this printer and my Aluminum Mendel http://www.thingiverse.com/thing:16076 print side by side here http://youtu.be/JysNv3Hi67k I posted a video at http://www.youtube.com/watch?v=4tpOokI6_Z0 I wanted to see if it could print vertically. It is printing a stretchy bracelet - http://www.thingiverse.com/thing:13505. I hope this inspires others to expand on this design. Instructions I added the controller with sd card reader and click encoder as seen in tommyc's excellent tutorial - http://tommyc-reprap.blogspot.com/2012/03/panelmax-tutorial.html. Now I can grab a coil of filament and the printer and print anywhere. This is printed in PLA. Drilling and tapping small parts is necessary to build this project. A drill press is nice, but it could be done by hand. The sliding surfaces fit well with my printer settings, but you can use a new, sharp file to remove a little material if necessary. Take your time with fitting the slides, a good fit without too much friction is needed. The x and y inner slides can be adjusted externally for a perfect fit. I use a very light film of silicone lube on the slides. I tried many different designs on the slides, but this one really works the best. The exploded view and BOM should provide enough info to make this project. I zipped the stl files because there are 22 total. I also zipped the entire Inventor project. I did not provide all the limit switch or power supply and switch mounts. 4/24/2012 I upgraded the slides to a hybrid roller version that is easy to print and assemble and has low friction and good precision. All the stl files are in the zipped folder. I was unsuccessful in simplifying the pulley arrangement by combining x and y movement, so I added a small, lightweight stepper for the x axis. This motor weighs only 4.9 ounces, compared to 12 for the standard steppers, so moving mass is still low. The motor should be run near its maximum current of 500 mA, so I recommend making the x motor mount out of aluminum plate to dissipate the heat. A drawing with dimensions is included in the zipped file. I also upgraded to the Misumi belts and pulleys. I think the smooth action is worth the extra cost. 4/27/2012 An exploded view drawing of the hybrid roller slide has been added below. The BOM is on the exploded view drawing.

With this file you will be able to print Pocket Printer Upgrade - hybrid roller slides with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pocket Printer Upgrade - hybrid roller slides.