Printed V-Laser - BiBu

thingiverse

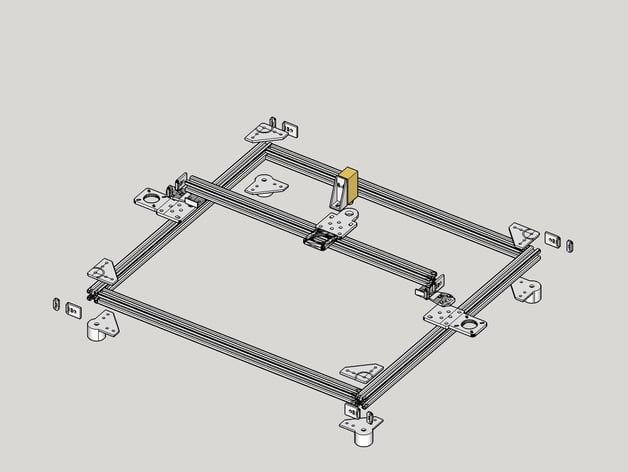

Hi! Due the nice response from the communty with LiBu, a printed mini laser engraver structure, we proudly present BiBu, your BIG Burner! BiBu, as its little sister, is a laser engraver engraver structure, the initial idea was a fully 3D printed structure, but in many ways, to 3D print a big structure is virtually imposible taking in consideration that it must be precise and sturdy. To fight that, we did chose an Open Hardware aluminium profile to make the long structure parts, V-Slot, because there are many printable parts out there, and the smooth linear motion that features is well balanced with the price and availability, also, there's a an awesome community around the product and derivatives Then we found this on the nets, while searching for a V-Slot distributor: http://openbuilds.org/?category=laser-cutter-builds&id=304 A whole world of information, an incredibly clever pinion/belt systems ideas, this makes the engraver able to work on walls and non-horizontal surfaces, based on V-Slot, and with a huge work on information about the electronics. So we took the site as a base to make our "fully 3D printable" big laser engraver. Check the site, an amazing work that worth the study. Finally we closed the design using: //// HARDWARE //// 3 NEMA 17 motors 4 x 50cm 2020 V-Slot aluminium profile *1 1 x 47cm 2020 V-Slot aluminium profile 3 x GT2 Aluminium pulley 4 x 55cm GT2 Belt 12 x V-Slot Delrin mini v wheel Kit *2 N x M3x12 //// 3D PRINTED //// 2 x Y-StepperCarry 1 x laser_StepperPlate_X 2 x axis_spacer_X_HolderV5 6 x V-slot-belt_end 1 x laser_support 4 x upper_corner 4 x bottom_corner *3 N x V-Slot Nuts All printed parts have a slight clearance on the sizes and diameters (about 0.2mm), specially thinking in FDM users. *1: To cut costs, you may use standard aluminium extrusion (cheaper) in the sides that are not involved with the linear motion, but remember that the nuts are diferent. *2: There are some methods to cut costs in this mini v wheel parts, using 3D printed rollers for motion (not tested, and adds extra screws/spacers/... that come with the miniwheel kit) *3: Our prototype bottom corner is designed for enclose 4 x printer rubber rollers, extracted from an old printer, to act as supports, but the bottom corner is extracted from the upper one, so there are many options to make proper supports just adding a few walls. For electronics, we used a cheap laser engraver controller board, thore are sold in many sites nowadays. As always, this project is deeply inspired by the work of other people who likes to make things, We'll try to list them all, forgive us if we miss someone: For the projects that made us dream with big lasers. Actually you triggered the LiBu project. :) http://www.instructables.com/id/Pocket-laser-engraver/ andhttp://www.instructables.com/id/Disassembling-a-CDDVD-reader-and-reusing-its-parts/ andhttp://www.instructables.com/id/Frankenstein-Laser-Engraver/ For their accurate work in traducing the Open Source hardware to cheap and easy to print parts http://www.thingiverse.com/thing:810785 http://www.thingiverse.com/thing:810785 There are many other alternative rollers to replace the mini wheels, but we stumbled upon this ones. http://www.thingiverse.com/thing:282178 And many many more that we can't remember, thanks too :) WARNING!!! REMEMBER THAT A LASER MAY SERIOUSLY AND DEFINITIVE HARM YOUR EYES, DO NOT EVEN START THE LASER PARTS IF YOU DIDN'T GOT A GOOD PAIR OF GOOGLES, AND REMEMBER THAT THEY HAVE TO BE SPECIAL FOR YOUR LASER COLOR (WAVELENGTH). BEWARE THE IR LASERS, YOU CANNOT SEE THEM BUT THEY'RE AS HARMFUL AS THE OTHER TYPES.

With this file you will be able to print Printed V-Laser - BiBu with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Printed V-Laser - BiBu.