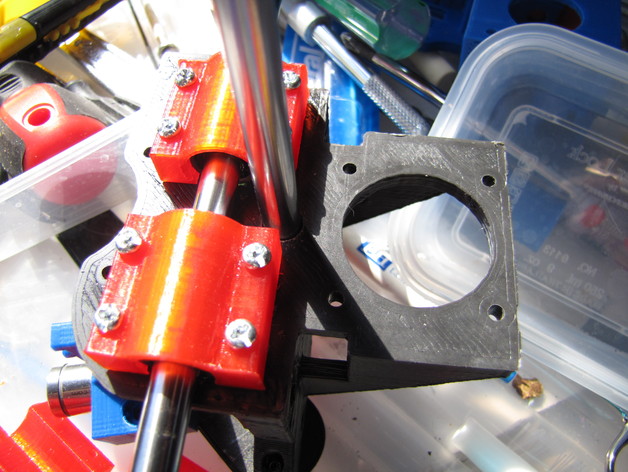

Printrbot base with z-motor support.

thingiverse

The standard base allows Z-motor rocking, but this version prevents it. Optional linear bearing clamps replace zip-ties for y-bearings, with 4 holes for screws; additional two holes are included for flexibility in using 2 or all 6. Zip-tie slots remain intact. The motor is shifted 0.5mm to match the spacing of traveling Z-nut and smooth rod. Additional features include tapped screw holes for locking smooth rods and base mounting. Y motor functionality is fine but may be improved with future support. Z+Y assembly works well, though spanner access requires improvement in CAD file. Test prints at .1mm show no ripple. Printing at .4mm due to slic3r issues with smaller layers. 2.6mm holes are M3 tapped. Clamp screw over-tightening warps base. Clearance between clamp and hotbed mount screw is slim. Y limit switch glued in place, eliminating adjuster screw need. Motor bracing slot fits 5/16 nut during assembly. Base printed in ABS at .3mm; spanner access improved but may still be problematic. Taller Y-bearing mounts used, ensuring they don't touch the motor and raising Y belt height by 4mm due to base printing imperfections. Washer placement on either side of bearings recommended. Custom belt posts required for standard Y clips use.

With this file you will be able to print Printrbot base with z-motor support. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Printrbot base with z-motor support..