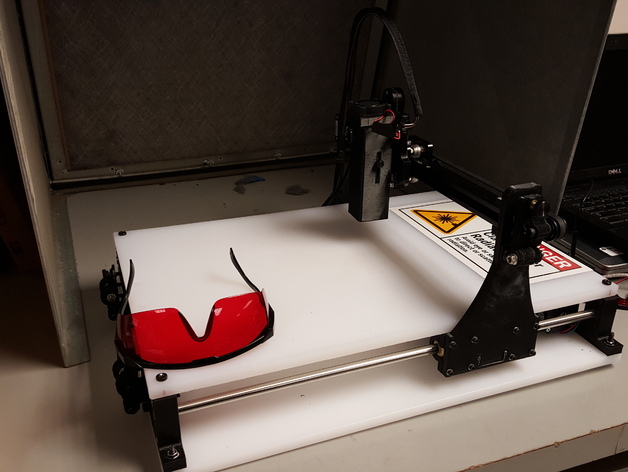

Project: Laserscythe - Another Open Source laser engraver using recycled doohickeys

thingiverse

The project you've outlined is a comprehensive plan for teaching students about lasers, laser engraving, and the artistic and scientific aspects of working with these technologies. It's great to see that you're emphasizing safety from the outset, which is crucial when dealing with powerful lasers. Here are some additional suggestions and considerations to enhance your project: 1. **Incorporate real-world applications**: While teaching the science behind lasers, also highlight their practical uses in industries like manufacturing, medicine, and telecommunications. This will help students see the relevance of what they're learning. 2. **Invite industry experts**: Consider inviting professionals from related fields to give guest lectures or workshops. This can provide students with valuable insights into the latest developments and technologies in laser applications. 3. **Encourage collaboration**: Pair students up for group projects, where they'll work together to design, create, and test their laser-engraved art pieces. This will help them develop teamwork, communication, and problem-solving skills. 4. **Safety protocols**: Establish a clear set of safety guidelines and procedures for working with the lasers. Make sure students understand the risks involved and take regular breaks to avoid fatigue. 5. **Incorporate hands-on activities**: In addition to theory lessons, incorporate hands-on activities that allow students to experiment with different materials, settings, and techniques. This will help them develop practical skills and problem-solving abilities. 6. **Use various teaching methods**: To cater to different learning styles, use a mix of lectures, demonstrations, group discussions, and hands-on experiments. This will ensure that all students have opportunities to engage with the material. In terms of the rubric and assessment, you can consider the following: * For an art class: Evaluate student submissions based on creativity, technique, and overall aesthetic appeal. * For a physics class: Assess student understanding through quizzes, exams, or lab reports that focus on laser fundamentals, safety protocols, and scientific principles. * For a robotics class: Evaluate the students' ability to assemble and operate the laser system, troubleshoot issues, and optimize performance. Regarding handouts and assets, you can use the provided resources as a starting point. Consider adding more resources, such as: * Online tutorials or videos that demonstrate specific techniques or safety procedures * A list of recommended materials and suppliers for laser engraving * Examples of successful projects or case studies from industry professionals By incorporating these suggestions and considerations, you can create an engaging and comprehensive project that teaches students about the art and science of laser engraving.

With this file you will be able to print Project: Laserscythe - Another Open Source laser engraver using recycled doohickeys with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Project: Laserscythe - Another Open Source laser engraver using recycled doohickeys.