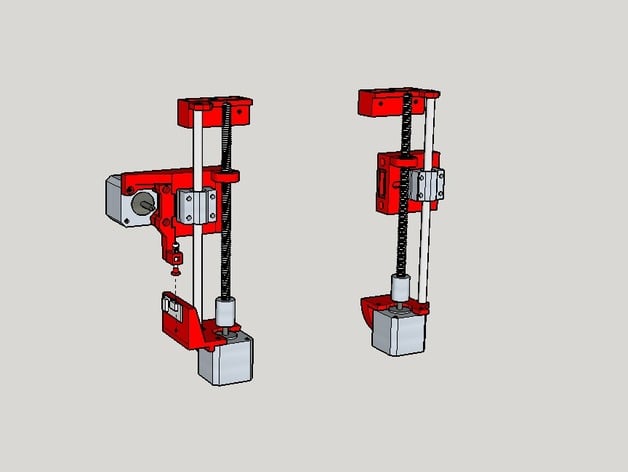

Prusa i3 Leadscrew, Bearing, ZStop, Belt tension upgrade

thingiverse

This is an upgrade design for my Reprap Prusa i3. It includes X Motor and Idler end replacements to make use of trapezoidal lead screws, improved bearings for the smooth rods and a belt tensioner adjustment. I found the original design using the original linear bearings to be fragile. I've also added a Z Stop to the motor end. I've included holes on the top z shaft mounts for KP08 pillow block ball bearings (https://www.amazon.com/gp/product/B00W8W7RNG/ref=oh_aui_detailpage_o04_s00?ie=UTF8&psc=1) to further steady the trapezoidal lead screws. I don't have them installed on mine at this time however as my motors won't drive the additional load they impose. Thanks to:http://www.thingiverse.com/thing:111903 for the X adjust inspiration. Although I redrew everything from scratch, the design is almost identical to burtdonalds. http://www.thingiverse.com/thing:542892 for the Z end stop idea. I've used the Blackhawk Prusa i3 ReWork - Adjustable Z Endstop in my printer, and incorporated the design into this upgrade. Take a look at my X Stop design at http://www.thingiverse.com/thing:1798572. EDIT: Updated the Z Shaft Mount STL files as it appears I may have had one wrong. My apologies. I've added different length Z Stop arms that mount to the X Axis assembly to accommodate different extruders. Pick the one that works for you. The short version should always work, but will require a longer screw. The medium version is the original length. I don't know if the long version will be of any use to anyone, but it is included. EDIT 08-08-18 Added the SketchUp file so that others can improve upon the design. I've effectively abandoned my i3 clone for the time being as I am working with another printer when I have time. Print Settings Printer Brand: RepRap Printer: Prusa i3 Rafts: No Supports: No Resolution: 0.2 Infill: 20% Notes: Support is needed for the Z Stop arm, the X Motor end, and the left side Z motor mount. I may manually add some support material to these parts in the model files as Slic3r tends to add support even where I don't need it. Custom Section Required hardware, etc. T8x2 (200 mm, single start) trapezoidal lead screws - 2 ea. 5mm to 8mm NEMA 17 coupler - 2 ea. KP08 Pillow Block bearings - 2 ea. (optional) SCS8UU Linear Motion Ball Bearing - 2 ea Misc. hardware. The left X motor will require two longer screws then the tradition Prusa i3 to accommodate the z-stop. The SC8 bearing hardware is a new requirement, as well as the belt adjust screw and nut. I used a spare spring on the Z stop screw to prevent it from changing position from vibration.

With this file you will be able to print Prusa i3 Leadscrew, Bearing, ZStop, Belt tension upgrade with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 Leadscrew, Bearing, ZStop, Belt tension upgrade.