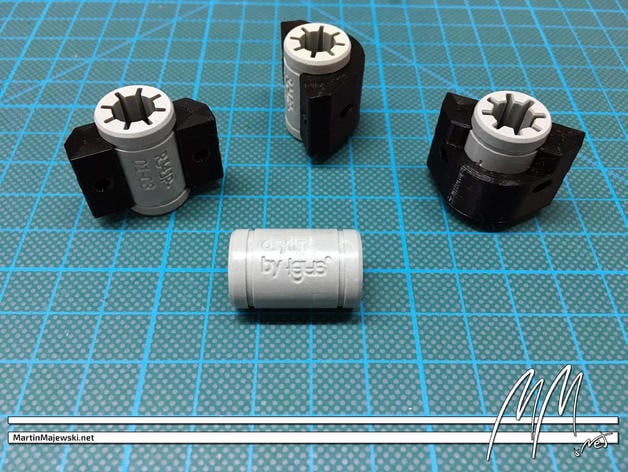

Prusa i3 MK2: V2 holder clips for Y-axis' bearings (LM8UU and igus drylin RJ4JP-01-08)

thingiverse

ATTENTION: Please read the project's update notes at the bottom of this page! I add to my effort to make the linear system of the Prusa i3 MK2 more stable, reliable and more comfortable to adjust these clips for the ordinary LM8UU ball bearings, which come with the machine. As with Thing 1837936 (http://www.thingiverse.com/thing:1837936) you don't need the weak zip ties any longer. Instead, you can mount your bearings "pre-aligned" to the Y-carriage by using two M3 screws per bearing. A further advantage is that the bearings are now aligned in the center of the Y-carriages notch. So there is no longer the risk of misaligning the bearings vertically. Nevertheless, the Y-carriage has still the full range of operation, because the clips for the side of the carriage with the two bearings are designed to slide into the gab of the frames corner pieces. There are still two things to consider: Though I had the LM8UU bearings and tested the fit of the clips on them, I have not tested them mounted directly on my machine. The reason is that both of my machines are equipped with the igus RJZM-01-8 bushings and in heavy use. So I ask the Thingiverse community to give me feedback on how the clips perform and what I should improve. According to nillabean (YouTube Video: VYW1p3T9tKo), the drylin igus RJ4JP-01-08 are very good, stiff and yet affordable linear bearings (not to confuse with the omnipresent RJMP versions). I have tested it myself and also got positive feedback from the community. They fit, and therefore the RJ4JP-01-08 are now "officially supported" by these clips! :-D If you like to buy the igus DryLin RJ4JP-01-08 bearings, then please consider buying it via my affiliate links provided next. No costs for you but you help me pay my bills. http://amzn.to/2BkMx1h (Amazon Germany) http://amzn.to/2BijLOK (Amazon UK) Thank you! Please also take a look at my other designs, printer parts, and tools. If you like to support me and my work, please consider following me on: Thingiverse MartinMajewski.net Twitter Instagram YouTube Sending a tip over Thingiverse is much appreciated and will provide me with coffee to stay productive. Please also consider buying your next gear via one of the affiliate links found inside my Thingiverse project pages or directly over the following links. Amazon.de Amazon.co.uk eBay Germany GearBest.com Print Settings Printer: Original Prusa i3 MK2 Rafts: No Supports: No Resolution: 0.2 mm Infill: Not important Notes: Use as many perimeters (shells) as needed to fill up the gaps. I used six on my 0.4 mm nozzle. I wouldn't recommend a brim because it makes the cleanup more difficult. You need 2x DoubleBushingSideClip 1x SingleBushingSideClip Orient the DoubleBushingSideClips correctly, so that the carriage can move along the entire length of the shafts. Post-Printing Clean your print from any unintended filament remains, like a brim. It is crucial that the bearings do not get misaligned by any derbies. The bolts that showed to have a perfect fit are M3x16 - I use stainless steel 2.5 mm hexagon socket screws with a cylindric head like also found inside the Prusa i3 MK2 kit. Project Updates No. 3 Besides the positive feedback that the clips also work with the igus drylin RJ4JP-01-08, I have also tested it myself now. They fit! Many thanks to igus for sending me the test samples! :-) So this is no "work in progress" anymore. No. 2: Version 2 (V2) of the clips is now online. You'll find the clips as single objects or as a complete set to download and print. Changelog: The clips now hold the LM8UU bearings more tightly The bearings are pressed against the Y frame to stop them from spinning. The M3 screw holes are narrower now to provide better grip for their thread. No. 1: So, I made the changes suggested by bret4 and tried different approaches of how to reverse the screw direction. The good... 1) I lowered the clearance of both, the bearing hole and the screw holes. Right, this was a good point. Both are now much tighter in fit, and should not wiggle or get loose anymore. 2) I lowered the surface that faces the Y-carriage frame by 0.2 mm (one layer's height), which again tightens the bearing much more by pressing it against the carriage frame. The bad... As shown on the following pictures reversing the screw direction results in a big problem: The screw-heads are crashing against the X-Y-metal-frame. My frame is already lower than Prusa Research suggests in its assembly manual, because my frame also rests on the table where the printer stands. Every other user that has assembled the frame as suggested by Prusa will obviously have the same trouble. https://dl.dropboxusercontent.com/u/4928832/lm8uuClipsProblems/ZylindricButtonHeadComparison.jpg https://dl.dropboxusercontent.com/u/4928832/lm8uuClipsProblems/ButtonHeadScrew.jpg https://dl.dropboxusercontent.com/u/4928832/lm8uuClipsProblems/ZylindricScrew.jpg https://dl.dropboxusercontent.com/u/4928832/lm8uuClipsProblems/CrashAgainstTheFrame.jpg The ugly... Trying to move the screws more towards the Y-carriage frame to hide the heads inside the clips and preventing them from crashing against the X-Y-frame results in an ugly geometry (with a big hole). This would affect the stability of the clips, and the screw heads would press against the bearings, which could misalign them again. Anyway, I will publish the tighter fitting version later today. The screw-reversal will be held back until I find something that works better.

With this file you will be able to print Prusa i3 MK2: V2 holder clips for Y-axis' bearings (LM8UU and igus drylin RJ4JP-01-08) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 MK2: V2 holder clips for Y-axis' bearings (LM8UU and igus drylin RJ4JP-01-08).