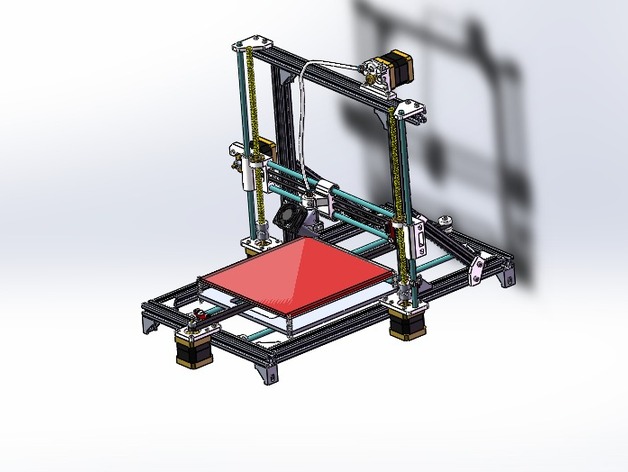

Prusa i3 rework in Aluminumm

thingiverse

In October 2014, in China, I published tutorials posted: http://tieba.baidu.com/p/3356312382. Teach you 1000 yuan DIY a 3 d printer.Get a hot, at the same time, our team, according to the problems, reflect lovers of design that a high cost performance of the whole aluminum 3 d printers. Today, we open our all documents, SolidWorks 2014 drawings, the drawings can be edit.You can according to the information in our website and our drawings for procurement, production, we also hope the problem you found him and through your own wisdom to improve it and then share your wisdom. Learn more at https://www.cerambot.com/ You can back CERAMBOT on Kickstarter today at the link below:https://www.kickstarter.com/projects/210413417/1934214216?ref=615030&token=9d0a0c53 JOIN OUR COMMUNITY Facebook: https://www.facebook.com/CERAMBOT How I Designed This Our Team Our team is a group of 90 after a technology curtilage, love science and technology, love, love for 3 d printing let us come together.We design, in their spare time on weekends to debug the circuit system, at the same time, we and the 3 d printing lovers all over the country through online cooperative product design assessment of cloud, assembled from all over the country's wisdom and experience, dozens of Yi Gao, only one possibility - aims to design a high performance to price ratio. Open source 3 d printers and can replicate. Our Advantages 1.2020 profile aluminium frame: material of solid, stable structure, overcome the fuselage defects, shaking the acrylic version of the abuse of general use probably will fall apart a few months. Remote reel off raw silk from cocoons, the speed and accuracy of maximum benefit for using remote reel off raw silk from cocoons, short-range extrusion speed frame shook with dwyane wade, at the same time improve the printing speed. Double fan design: single fan design to bypass dangling such as print, and double fan to a certain extent, alleviate the problem, unsupported print can be a short distance. T8 screw: the original design in order to popularize technology, adopting low (keng) (die) of normal tooth, Z axis caused by serious water ripple, to ensure the quality of printing, we use T8 screw, the result is good. The Y axis transmission update design: change the Y axis transmission way, reduce unnecessary space.Increases the LCD LCD, can realize offline print, at the same time support the SD card. Information about prusa i3 rework The weight: 7.2 KG The fuselage size: 400 mm 290 mm height 300 mwide Molding size: floor height 200 mm 200 mm 200 mm (because of open source and support DIY, print area is the ascent to 300 mm 300 mm * 300 mm) Print layer thickness: 0.05 0.4 MM Material: PLA, ABS.Material: Ø 1.75 MM The print head move speed: 20-300 - mm/s Print path: USB and SD card offline printFirmware: Marlin - the FirmwareOperating software: Repetier - Host supports Windows;Linux;Mac OSSlicing software: slic3r, cura, Simplify3D, skeinforgekis, etc Material: 2020 industrial aluminium profile Screw: T8 screw Thermal head: 2015 latest edition E3D - volcano extrusion head, open source solution, replaceable extrusion head diameter, 0.2, 0.3, 0.4 nozzle replacement, good heat dissipation, specialized in all kinds of plug problem Hot bed: 12 v and 24 v, 120 w power aluminum hot bed, best heat deformation, thermal uniformity is best, refused to become warped edge. Extruder: general extruder, can be convenient for fast color change, realize the pseudo color printing Main board: 2560 + ramps of export quality control system, the open source solution, increase support WiFi, renew power module, convenient to DIY

With this file you will be able to print Prusa i3 rework in Aluminumm with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 rework in Aluminumm.