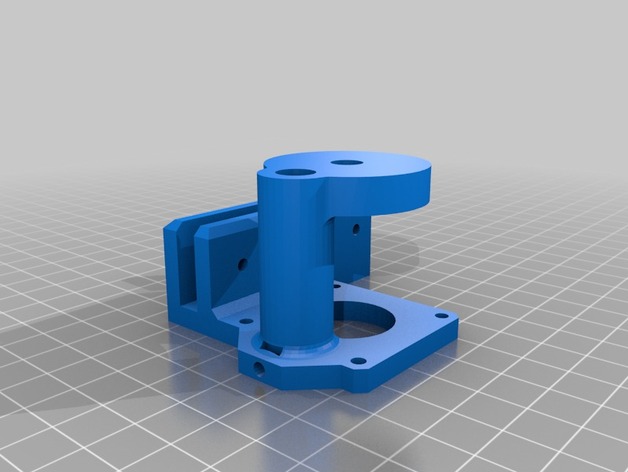

Prusa i3 Z axis Up2Down

thingiverse

I Always Want To Try To Mount My Prusa I3 Z Axis Upside Down Because My Version Is Boxed And Extremely Difficult To Change The NEMA's Z Motors. There It Is, My New Z Up2Down System With Single Or Dual Anti-Wobble Features, Z Couplers, And It Works Smoothly! I'm Open To Modifications And Suitable For Prusa I3 Single Plate And Stabilized Versions, Both In 6mm Configurations With 8mm Smooth Rods And 5mm Threaded Rods. It Requires 2 Additional Holes Per Side In The Plates, But Is Completely Optional (Although Very Highly Recommended). Depending On Your Prusa I3 Flavor, The 8mm Smooth Rod And The 5mm Threaded Rod Could Result In A Little Shorter Length. My Friend Resolved This By Creating 2 Additional Holes In The Plate To Fix The Down Side. Instructions: Print At Least 0.2mm Layer And 70% Infill With Minimum 3 Perimeters. If Sliced With Slic3r V1.2.1, Use The XYSizeCompensation Feature Using The Formula: XYCompensation = NozzleDiameter / 2. For Example, If You Have A 0.35mm Nozzle Diameter, Then The Compensation Will Be 0.175mm Because Slic3r Calculates The Filament Path In Its Center, Not Within Its Diameter Once Extruded (However, This Calculation Is Quite Needed). For The Top Motor Holder, There Are Two Versions: One With A Tower That Maximizes Anti-Wobbling And The Other Without It. Print The First Version Only If You Own A Dual Extrusion System And Have Some PVA Filament Available Because Printing It Using Support Without PVA Can Be Extremely Challenging. BOM: 2/4 X Ball Bearings 625 ZZ (ID 5mm - OD 16mm - HT 5mm) 6 x Bolts 3x10 6 x Nuts 3mm 10/12 x Bolts 3x25 10/12 x Nuts 3mm

With this file you will be able to print Prusa i3 Z axis Up2Down with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 Z axis Up2Down.