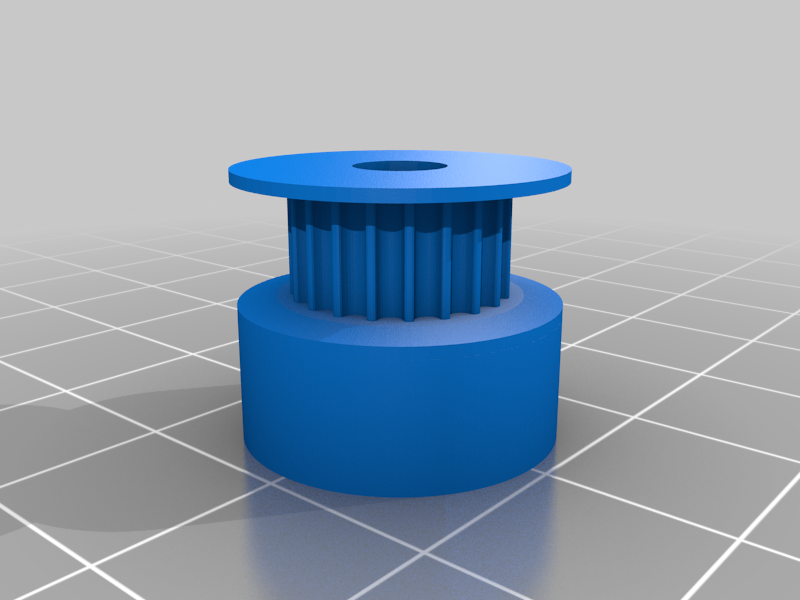

Pulley (customizable, with lots of tooth profiles)

thingiverse

Customizable Pulley with Various Tooth Profiles This OpenSCAD script models different timing belt pulleys that can be printed on a regular FDM printer. Available Options Profile * Number of teeth: 10-100 * Teeth profile: + MXL + 40DP + XL + H + T2.5 + T5 + T10 + AT5 + HTD (3 mm, 5 mm, 8 mm) + GT2 (2 mm, 3 mm, 5 mm) * Motor shaft diameter * Toothed part length: 3-30 mm * Height of "base": 0-30 mm * Diameter of "base": 10-50 mm Top and Bottom Flanges * Enable or disable top flange * Top flange height (above tooth) * Top flange width (thickness of flange) * Enable or disable bottom flange * Bottom flange height (above tooth) * Bottom flange width (thickness of flange) * Set bottom flange bottom surface diameter equal to the base diameter Holding * Screws disposition: - None (disables placeholders) - 1 screw - 2 screws at 90 deg - 3 screws at 120 deg - 4 screws at 90 deg * Nut shape: + Hexagonal + Square * Screw profile: + M1 + M1.6 + M2 + M2.5 + M3 + M4 + M5 + M6 Idler Bearings * Add bearing grooves (enables or disables bearing grooves) * Bearing grooves diameter (should be close to bearing outer diameter) * Bearing grooves height (should be close to bearing width) Tweaks * Additional tooth width (scaling tooth for good fit) * Additional tooth depth (if you need more tooth depth, adjust the constant above) * Surfaces quality (polygon multiplier for smoother surfaces): + Standard + High + Highest + Best * Flip pulley upside down (if pulley diameter bigger than base, flip it upside down for easier 3D-printing) Authors and Contributors This project is my attempt to organize this useful thing and share it for further improvements. I've found it on Thingiverse published by D14 on October 30, 2016. Initially it was made by droftarts in January 2012. I have improved some things (made code more readable, added options, improved flanges shape). Later I have found many remixes with useful options. I will try to add their functions too. This will be better to improve one tool with lots of functionality than having many separate "a little improved". Converting from SCAD to STEP If you need a STEP file instead of using STL, you can import SCAD to FreeCAD and save it as STEP there. Note that first you will need manually edit SCAD to reflect all customizable options in code.

With this file you will be able to print Pulley (customizable, with lots of tooth profiles) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pulley (customizable, with lots of tooth profiles).