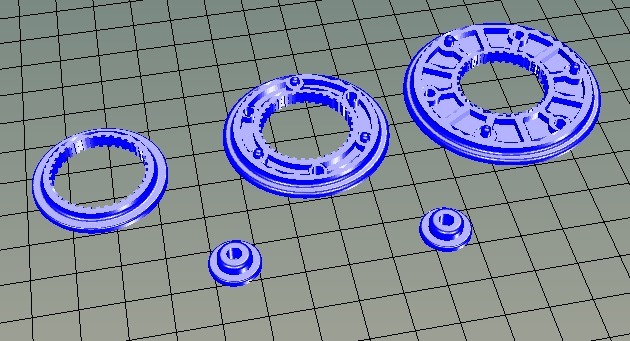

Pulleys using 608 bearings

thingiverse

I was making some pulleys for a tension-sensing end-of-filament sensor (still working on it... soon). Yes, I ended up having to keep upping the diameter of the pulley since filament doesn't like to bend in small radiuses! But I thought someone else might be in need of some nice solid pulley designs. The distance within each pulley is 4mm (but the edges are tapered for strength, so 2mm or 1.75mm would be a good fit). There are three diameters here, 26mm, 35mm and 45mm (that's the diameter the string, filament, or belt rides on). You can use all those 608 bearings you have now eating up space since the fidget spinner craze had died down! You'll need two halves for whichever pulley you make, and two end buttons (these buttons will space the outside of the pulley about 1.5mm from the surface the button gets mounted to). Best to put a drop of superglue inside the assembled halves. The larger sizes could also use a drop of superglue on the posts that hold the outsides together. Press the bearing in right after you put the glue on, putting these rings (assembed together) on a piece of waxed paper on a hard, flat surface. Push the bearing through hard till it meets flat against the same surface, that should keep everything square and make a good solid piece. I've done some in PLA and in PET-G, should work ok with ABS too I imagine. Hope you find a use for these/

With this file you will be able to print Pulleys using 608 bearings with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pulleys using 608 bearings.