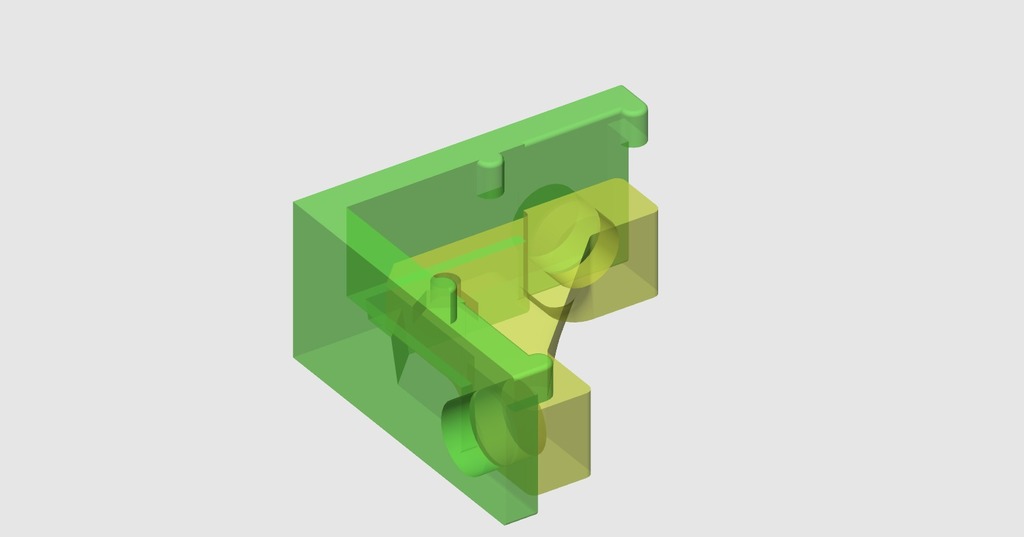

Quick Corner Mag Glass Clamp

thingiverse

I simply use standard 3 mil glass cut at a hardware store on my print bed. As such they are rarely cut to a tight enough tolerance to have it just drop snuggly into stationary corner brackets. This bracket design uses 3mm x 8mm dia neodymium magnets which quickly snap to conform to the glass edges. By using a couple of 3d printed clips I have a fast and low profile glass mounting system that doesn't require glass to be precision cut. Drop the glass on. Clip up the corners which squares things up and snap on a couple of printed clips. https://www.thingiverse.com/thing:311665 If I'm printing a large print with a lot of mass I will add large metal paper clips for extra insurance but for most smaller prints this arrangement has proven to be sufficient. Press in magnets with a small application of CA glue. Press in a 3mm nut. Run bed screw down through assembly and snug to bed. Install spring. Install wingnut. Probably best printed in ABS for longevity as with all these clamping devices used on a heated bed.

With this file you will be able to print Quick Corner Mag Glass Clamp with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Quick Corner Mag Glass Clamp.