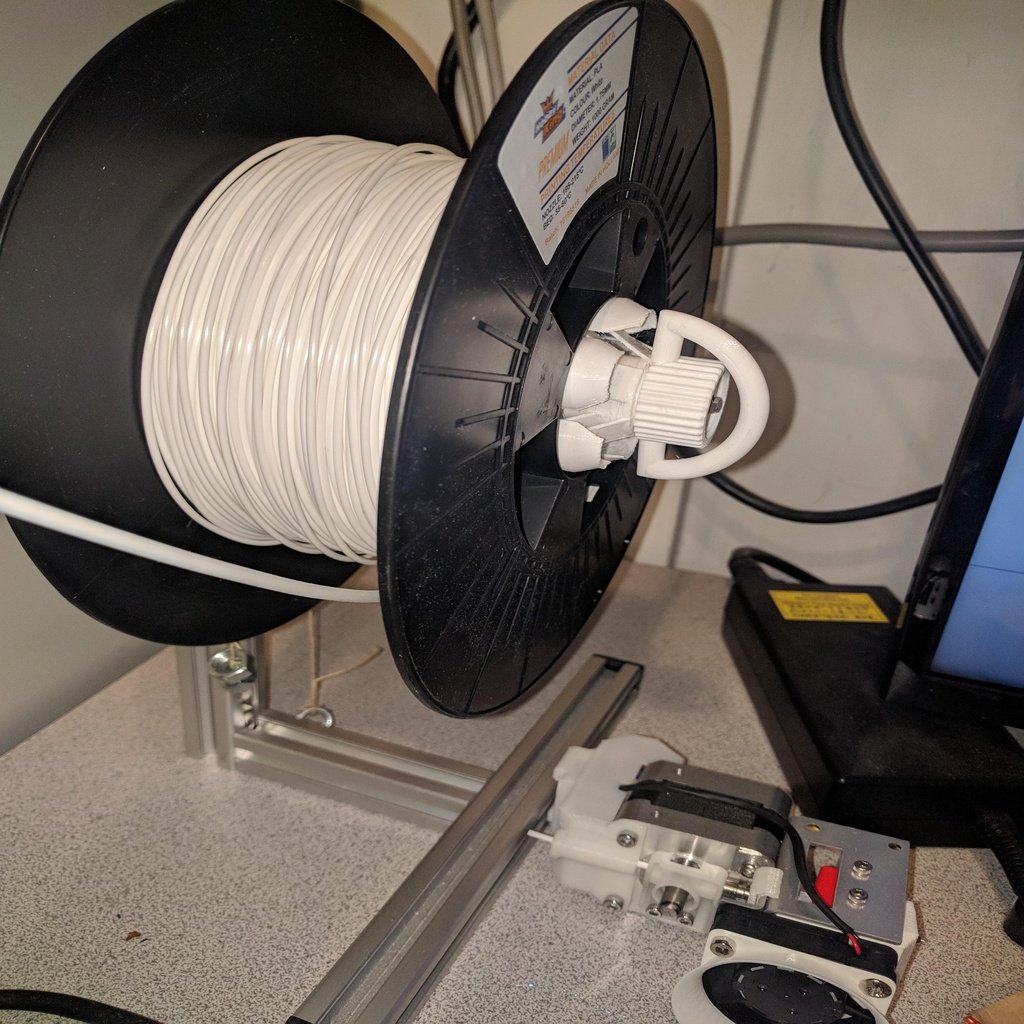

Quick release expanding spool holder

thingiverse

This is rev 2 of my flexible filament expanding spool holder (https://www.thingiverse.com/thing:3939856 ), however, this model requires slicing with Z-hop to successfully print. This model has 25 springs which keep the 5 expanding arms parallel. Works great even with lots of stringing created by the Z-hop slicing option. Why? Any filament feed friction causes flexible and to a lesser extent other filament to behave like a stretched rubber band. This varies the amount of filament extruded and is visible in the finished print surface if you're lucky or the print just fails. The D shape part is a quick release lever. Actuating it 90 degrees expands the hub diameter by 2 mm. This allows single handed operation with a cantilevered mounting configuration. The first pic shows the a spool with the D lever in the locked position and in the 2nd pic the D lever is in the spool release position. Creating the mounting is up to you. A pulley on the back functions as a filament retraction device and a friction brake. It is a very very simple device. A string goes over the pulley and you put different weights on each end. In the pic I use nuts as weights. The difference in the weights creates a rewinding/retraction force on the pulley. The weight sum creates a friction clutch action. As filament is printed the heaver weight gets lifted up until the smaller weight touches the table and the clutch slipping action begins. I used a threaded rod as the mounting axle which supports 2 ball bearings that in turn support the spool assembly. I drilled and tapped a 1/4"-20 thread hole horizontally into 2020 aluminum extrusion to mount the threaded rod. You could use a larger hole and two nuts if you don't have taps or a long bolt with one nut. I also put an extra PLA nut on the lever end of the thread to prevent the ball bearing threaded PLA sleeve from moving. The expanding spool holder has an adjustment range from 50 to 60 mm in diameter and the toggle lever action alters the diameter by about 2 mm. The model is rigid and the adjustment can be set to break the model. Flip over the D lever and print with the flat face down. The design uses thin 0.8mm walls or two nozzle widths thick and they need to fuse together for strength so under extruding is a problem. The design uses 1mm pitch metric threads so over extruding is also a problem. So adjust the extruder first! Extrusion calibration nut and bolt test https://www.thingiverse.com/thing:3983705 new rev. The sliding collar to the tube has 0.05mm of radial clearance which axially centers the 5 expanding arms, if you do not have a good surface finish it will bind. I printed with a 0.1mm layer, 0.4mm nozzle and 0.4mm line (paving) width using fine print settings in Cura. The model took about 12 hours to print. The 25-flexure spring struts require cooling to print strongly. The slicer needs to generate support only to the bottom of the collar and the bottom of the 5 expanding arms. The sliding collar is positioned around but not touching the threads and during printing this provides slightly more radial clearance. I would strongly suggest slicing and printing the model successfully first before getting any other parts. I have sliced this from 30 to 50 grams and 30 is structurally on the weak side. You need two 8x16x5mm 688-ZZ ball bearings for the lowest rotating friction. I washed out the grease and sparingly applied a drop of very light oil. Filament spools are reasonably balanced but you can add a small amount of weight tapped to the rim and can make the balance perfect (only reasonable to do for flexible filament with thin walled prints). Friction averaging PTFE mount https://www.thingiverse.com/thing:3815678 Designed in Fusion 360 and printed on a Cetus MK2 extended using gcode generated by Cura Quick Tip: If you have a postal scale and write the weight on the side of new spools you can weight how much filament remains on a partially used spool. Have fun -Peter

With this file you will be able to print Quick release expanding spool holder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Quick release expanding spool holder.