Replacement Stepper Drives for Replicator 2

thingiverse

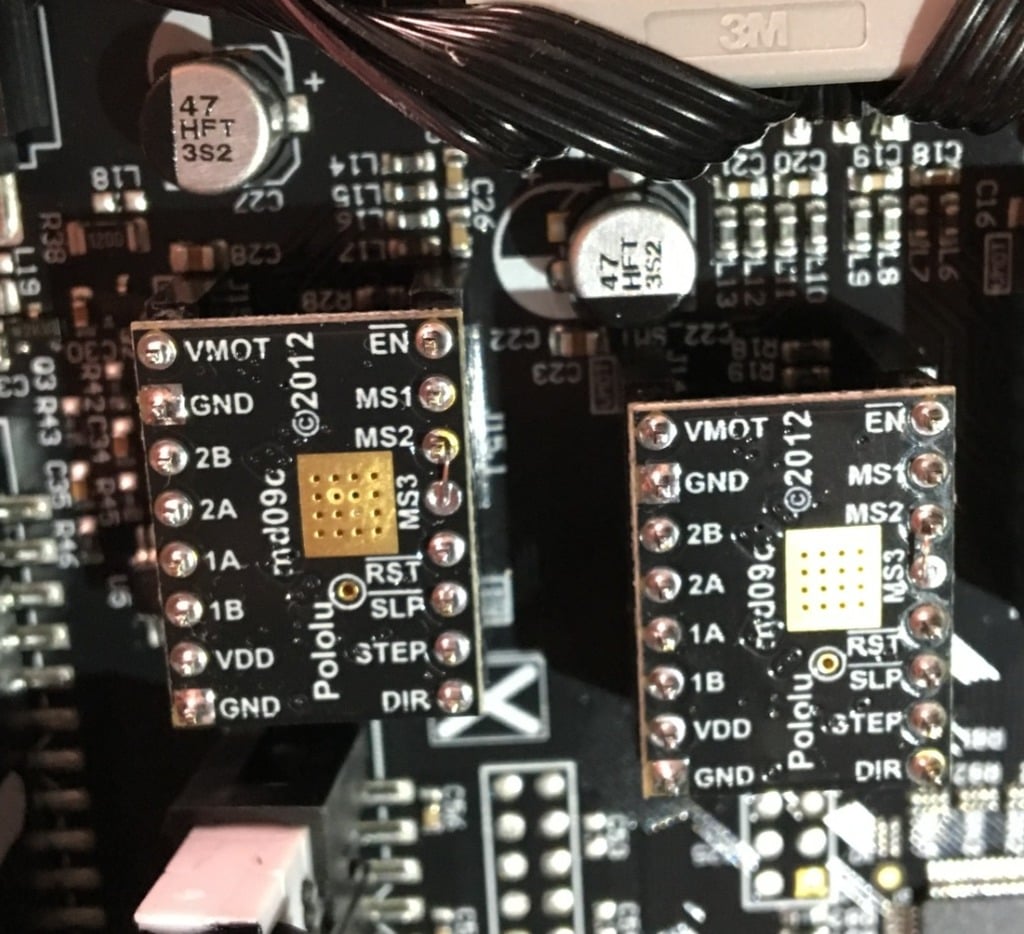

I got my hands on a Replicator 2 and the MightyBoard Rev H with a missing botstep and three blown BOTSTEP17Es ($50), so I went for the Pololu 2128 S4988 Stepper Motor Driver, Black Edition ($6.95) with the 68mΩ sense resistors, which is the version made since January 2017. I took voltage measurements of my working Rep 2s (Mightyboard Rev G & H) and carefully studied the schematic and datasheets of the A4982 (Botstep17E) & A4988 (Pololu 2128) to determine some important conclusions: 1. MS1 & MS2 are given +5V on all BOTSTEPs, which means the Mightyboard is doing 1/16 steps. MS3 on the A4988 should also be tied to +5V. 2. The Z motor Botstep's Vref into the A4982 is being fed 0.70V (Mightyboard Rev H). This equates to an Imax of 0.33A. Mightyboard Rev G measured 0.73V => 0.34A. 3. To get Imax on the Pololu 2128 (January 2017 or later version) to be 0.33A, adjust the potentiometer to 0.18V. 4. The X, Y and Extruder motor Botstep's Vrefs into the A4982 are being fed 1.68V (Mightyboard Rev H). This equates to an Imax of 0.78A. Mightyboard Rev G measured 1.70V => 0.79A. 5. To get Imax on the Pololu 2128 (January 2017 or later version) to be 0.78A, adjust the potentiometer to 0.42V. 6. The A4982 and A4988 are basically the same chips, performance-wise (most values are identical, including RDSon and have the same package thermal characteristics). The key differences are as follows: - The A4982 has a sleep mode - The A4988 has a 1/8 step mode and a 3rd mode select pin (MS3) - Both chips are available in different IC packages Tips: a. Getting to the Vref trim pot is impossible when put into breadboard or Mightyboard. Must use trial by error to get the voltages correct. b. Remove the header pin for MS3 and jump MS3 to MS2 with a small wire or solder blob. c. Label the Z axis module as Z Axis Only with a silver sharpie d. Put heat sinks on the X, Y & Extruder modules WARNING: The reason the Mightyboard is feeding Vref a voltage to the BotSteps is to allow it to adjust the hold current on the stepper motors. This lets them save power during heating up the extruder. So while the extruder is heating up, the steppers can be drawing less power. This can be seen in the start.gcode with a G130 command. I might not recommend these replacement drivers if you have a heated build plate and the stock 150W power supply. The power draw for the build plate, extruder, and steppers may exceed what the power supply can deliver. I would advise using a stiff 24V 300W or higher power supply. These have been working fine in a Replicator 2, no heated bed with stock power supply.

With this file you will be able to print Replacement Stepper Drives for Replicator 2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Replacement Stepper Drives for Replicator 2.