Replicator MightyBoard Protection Part 2: ESD Shielding

thingiverse

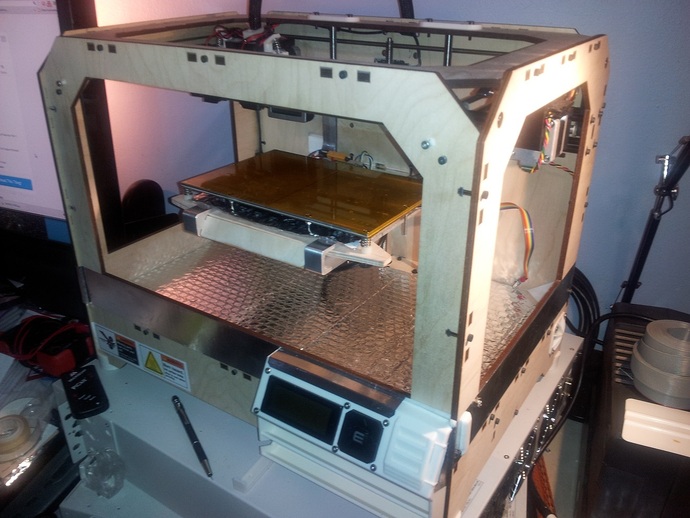

From Part 1, we know that Replicator MightyBoards occasionally blow up. One of the suspected causes of those blow-ups is Electro-Static Discharge (ESD). Part 1 offered some protection from ESD on the EndStop data lines; now, in this Thing, we'll try to improve on that to offer some protection to the Replicator in general. The most common source of ESD damage is from the human body, discharging an accumulated charge into a sensitive electronic circuit. You accumulate a charge via motion or friction with an object. You discharge when touching a conductive object; i.e., that spark when you touch a doorknob. One of the insidious things about ESD damage in electronics is that it is cumulative. You might zap your Replicator, and it keeps on working, so you think you've dodged a bullet. But the damage may still be there, waiting to accumulate further damage with the next zap, or just planning to spontaneously disrupt at some random time in the future. And here's another secret: ESD discharges that you may not even feel, may still damage your Replicator. To protect against ESD, this Thing suggests using a strip of conductive aluminum tape completely around your Replicator and grounding it, along with grounding the aluminum build plate (if used) and the aluminum platform arms (if installed). It's recommended that you consciously discharge yourself at one of these grounded points. This Thing can be implemented without installing the EndStopESD board from Part 1, but it is strongly suggested to install this Thing before installing the LCD ESD add-on board in an upcoming Part 3. Additionally, good ESD prevention practices should also be followed around your Replicator at all times.

With this file you will be able to print Replicator MightyBoard Protection Part 2: ESD Shielding with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Replicator MightyBoard Protection Part 2: ESD Shielding.