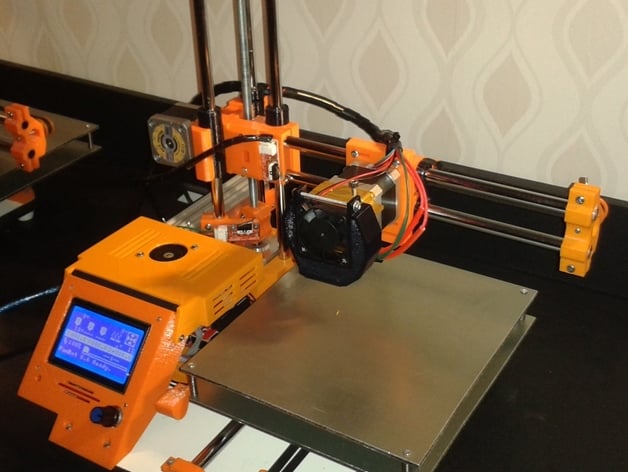

Reprap - Funbot i1

thingiverse

It looks like you've got a lot of great resources and information to share, so I'll break down your text into smaller chunks and respond accordingly. **Nozzles and Extruders** * You found a great alternative extruder on eBay that's made in the UK and has 1-2 week delivery. The price is slightly higher than the Chinese option, but it might be worth it for the faster shipping time. * I recommend using the small nozzles (0.4mm) on the x and y axes, as you mentioned they won't conflict with the stability of the z-axis. **Power Supply** * You linked to a power supply on eBay that should work well for your printer. Make sure to check the specifications and reviews before making a purchase. **Marlin Firmware** * You'll be uploading your prototype Marlin code, but in the meantime, you've shared some typical settings that need to be changed. * It's great that you're including configuration examples for various printer setups (e.g., Orca vs. Mendel Prusa). **Slicer Config** * You mentioned that slicer config needs to be loaded manually and saved separately. I'd recommend creating a wiki or a document with clear instructions on how to configure the slicer for your specific setup. **Other Peoples Designs** * Thanks for sharing resources from other people, such as the LM10uu replacement video series and the z coupler design from Thingiverse! These can be very helpful for inspiration and troubleshooting. Let me know if you have any specific questions or need help with anything in particular.

With this file you will be able to print Reprap - Funbot i1 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Reprap - Funbot i1.