RepRap Prusa X End Motor Braces

thingiverse

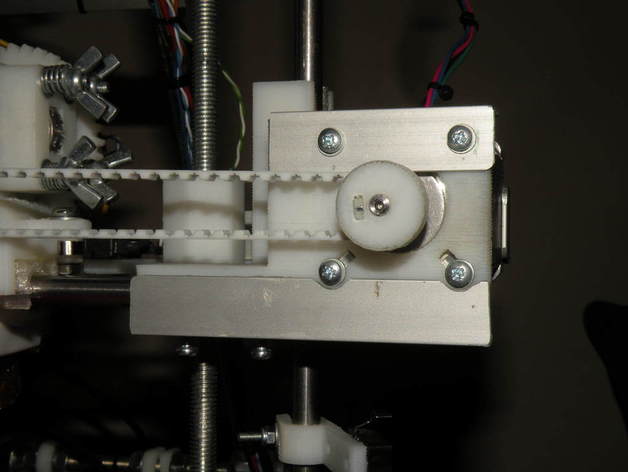

My Reprap Prusa is still in it's early life stages. Amongst some of the problems I have had to solve one is the X end motor parts which are a little flimsy. One problem that this created for me is that tightening the X carriage belt is difficult. The reason is that there is a fair amount of flex in the plastic part. I have read others who feel that the part has been stripped down a little too much and now is flimsy. Obviously you could create a new part with some more plastic in there to make it sturdier. However this means getting your printer up and running just so that you can strip it down to add the improved part. I was looking for another way to strengthen the part. In my parts cupboard I had some aluminium angle bracket which I shaped and bonded into place. I have created an SCAD file with the parts in it, though obviously this is to give a model to work from not to print from. With this alteration the X motor end becomes rock solid and tensioning the X carriage belt becomes a lot easier. I can't comment on if it improves the print quality noticeably as I won't have before and after to compare but I would imagine it would help if you are having backlash problems on the X axis. Instructions Buy some 1.5mm angle bracket from your local hardware store. Aluminium is fine and easy to manipulate, you could use steel though if you are happy to put some extra work in. Cut, drill and file your aluminium to shape. The parts on the pulley side of the stepper motor will probably be enough, but additional strength can be gained by adding the brace at the non-pulley side as well. The brace at the bottom of the pulley side is bonded in place as seen on the pictures. I used araldite two part epoxy which forms a very strong bond. The brace at the top of the pulley side is not bonded in but clamps stepper motor very firmly to the plastic. By spreading the force you can tighten better without breaking the plastic. You could bond it in, but replacing a dead motor would become near impossible. The brace on the non pulley end of the motor is bonded to the plastic. It is made up of two parts and cuddles the stepper motor. Tie wrap the parts as the epoxy dries and then attach and tighten your belt. You should see very little if any movement of the stepper motor.

With this file you will be able to print RepRap Prusa X End Motor Braces with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RepRap Prusa X End Motor Braces.