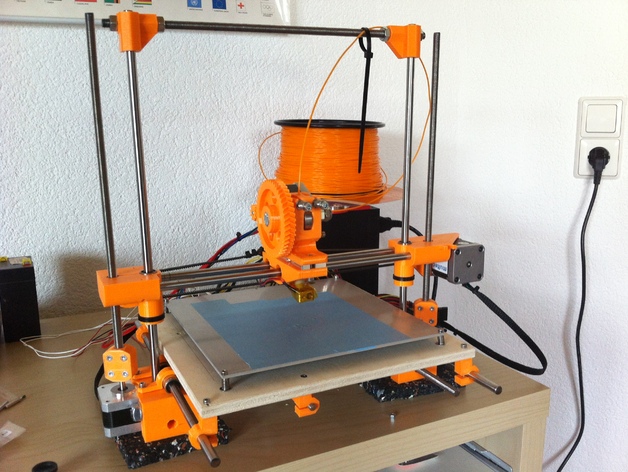

RepRap Wallace/Wallace++ Compilation Edition

thingiverse

Update: 17/03/15 Added y_motor_holder_rack.stl as the .scad file requires the original wallace scad config file. Added y bearing retainers. y_bearing_retainers_4x.stlthis is a set of 4 retainers nicely arranged y_bearing_retainers.stlone single retainer y_bearing_retainer_stopswitch.stly bearing retainer with an assembly for a stopswitch I personally do not use this. This is here just for principle of completeness. Description: This is a compilation of the original Wallace (http://www.thingiverse.com/thing:14208 ; be sure to check out whosawwhatsis's github for the current files at https://github.com/whosawhatsis/RepRap-Wallace) and the Wallace++ M8 Edition (http://www.thingiverse.com/thing:45207) plus a Y axis modification made by Komb (http://www.thingiverse.com/thing:37787) The base is from the original Wallace. The xend* parts are from the Wallace++ M8. I modified the diameters for the bearings to be a bit wider. I did not manage to get the bearings in with sponnets configuration. The Y axis mod replaces the belt with a rack & pinion system for more stability and rigidity. This was all printed on a QU-BD TwoUp with PLA. I use the Merlin Hotend on the Gregs Wade Extruder Reloaded without cooling. The Merlin hotend is designed as a passive cooled hotend and the first print test confirmed it's passive cooling abilities. However the PLA needs proper cooling to achieve a good print quality. The 3rd picture shows a 0.5mm wide wall-only cube. Left is 0.3mm layer height, right is 0.1mm @ 60mm/s (Perimeter). This was the very first print I did on the Wallace after I had calibrated all the axis and the extruder. RepRap Wallace in action printing the 0.5mm Thin wall from "The Essential Calibration Set" -> https://www.youtube.com/watch?v=FR-oc-ztBJA&list=UUXx2upMv_Z5ginBt-ge_1gQ Instructions This setup is configured for M8 rods except for the rack on the Y axis which is made for M6. Sorry no scad files yet. They need further refining and cleaning up for better overview and readability. For Z axis coupling I suggest any rigid coupler. Don't ever use flexible couplers on Z axis. I use Gregs Wade Extruder Reloaded on this printer with the Merlin Hotend (http://www.thingiverse.com/thing:18379 jonaskuehling_gregs-wade-v3.stl) If your print area is too small to print the rack, there is also the SCAD version in which you can reduce the teeth count to fit your print area. UPDATE: 19. September 2014 I realized that because of the way the extruder is mounted to the X-axis sled the tip of the hotend is slightly offset to the front of the printer. This means when centering the heat bed you have to consider that you must also offset the heat bed to get the full 200x200mm print area. I did not and just centered it in the middle of the substructre plate so I only got 200x180mm printable area. So you can decide if you either center the heat bed perfectly in the middle and offset the screws in the back that hold the heat bed substructre or leave the substuctre alone and offset the heat bed to the BACK.

With this file you will be able to print RepRap Wallace/Wallace++ Compilation Edition with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RepRap Wallace/Wallace++ Compilation Edition.