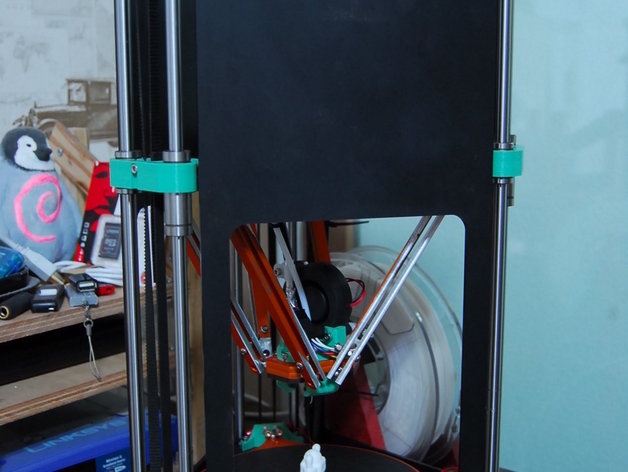

RepRapPro Fisher 3D Printer - print bed

thingiverse

Top and bottom plate thickness: 5.00 mm Side panels: 3.00 mm How I Designed This Metal Fisher (2017/1/30) Idler bracket that has thicker walls. idler-bracket-v2.scad uses "1244-Idlerbracket.STL". (Update 2016/9/26) Aluminium diagonal arms were too steep. I gonna try laser cut polycarbonate rods. I learned one hard lesson about electricity. Aluminium print bed has to be non-conductive. Fisher uses spring loaded print bed as Z probe. Three balls on the bed acts as probe swith. Make sure three balls are disconnected from aluminum, which means resistance between the balls should be infinite or mega ohm range. Spray non-conductive chemical or paint right after drilling the three holes where the ball seats. If you reverse this order, three balls becomes one big switch. It renders Fisher auto calibration feature supported by RepRapFirmware. Need stronger bed springs Aluminium bed will weighs over 300 g, which is two and half times of Acrylic bed's weight. This causes frequent layer shift. I reinforced the bed springs using ball-point pen's spring. Buy two ball-point pens. Cut the pen's spring half and insert into each bed spring. Change the Z probe setting in config.g file. Below is my setting. G31 X0 Y0 Z-0.1 P1000 ; Set the zprobe height and threshold (put your own values here) Fisher 1 3D Printer RepRapPro closed business right after it released Fisher 1. Former worker of the company is selling Fisher 1 kit and related parts on emaker.io. Software I used: OpenSCAD, QCAD Story: I modified the DXF file of RepRapPro's Fisher 3D Printer to make laser cut steel and aluminum parts. Around June 2015, RepRapPro released Fisher 3D Printer Beta version, which uses Deltabot technology such as Mini Kossel. The company offered sales price for beta version before it would finalize the Fisher 3D Printer. I was personally curious about other Deltabot 3D Printer made by well-known 3D Printer company at that time because I had some issues in my homemade Mini Kossel, especially objects that demands excessive retraction. The sales price about 200.00 British pounds. Shipping and handling fee of FedEx costed me over $200 USD by innocent mistake of a company. I ended up paying about $100 USD for the shipping fee. One important lesson I learned is to avoid FedEx like international career just by its name alone unless a third party would cover the outrageous shipping cost. The kit quality is excellent compared to cheap Chinese ones. Build instruction was through, the items were neatly packed. Also I felt good about helping well-known company in Open Source 3D Printing community. One major issue I found was most critical parts of Fisher were made out of flimsy Acrylic plastic. How not to crack one of the parts? I cracked one effector piece. Later on I cracked one front panel. I spent about twenty hours to assemble Fisher Beta and ran it two or three days. And then I decided to use it as a production machine. Reliability of Acrylic plastic parts was concern to me so I planned to replace all Acrylic parts with steel and aluminum ones. Base and top plates, 5mm steel Two front and one side panel, 3 mm steel 12 diagonal arms, 4 mm aluminum (original spec was 3 mm) Two effector pieces, 4 mm aluminum (original spec was 3 mm) I made two big mistakes here: Firstly, I don't recommend aluminum for parts that are delicate or requires precision down to 0.1 mm. The surface quality is rough, holes aren't round due to the low melting point of aluminum. The technician at the laser cut company called it "exploding hole". I should use 3 mm polycarbonate which could save hours of labor work. Secondly, I was in hurry and assumed 1 mm thicker plate would be better but it would not. In precision machine, all the specs in number mean something behind them. One print bed, 5 mm aluminum I gonna replace 12 diagonal arms with decent rod end bearings and carbon or aluminum rod if possible. The designers in RepRapPro demonstrated ingenious way to drop the cost of kit but not worth it for serious 3D Printer that runs 10 to 8 hours per day. Moai glasses holder

With this file you will be able to print RepRapPro Fisher 3D Printer - print bed with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RepRapPro Fisher 3D Printer - print bed.