"Reverse Bowden" Filament Guide System For Anet A8

thingiverse

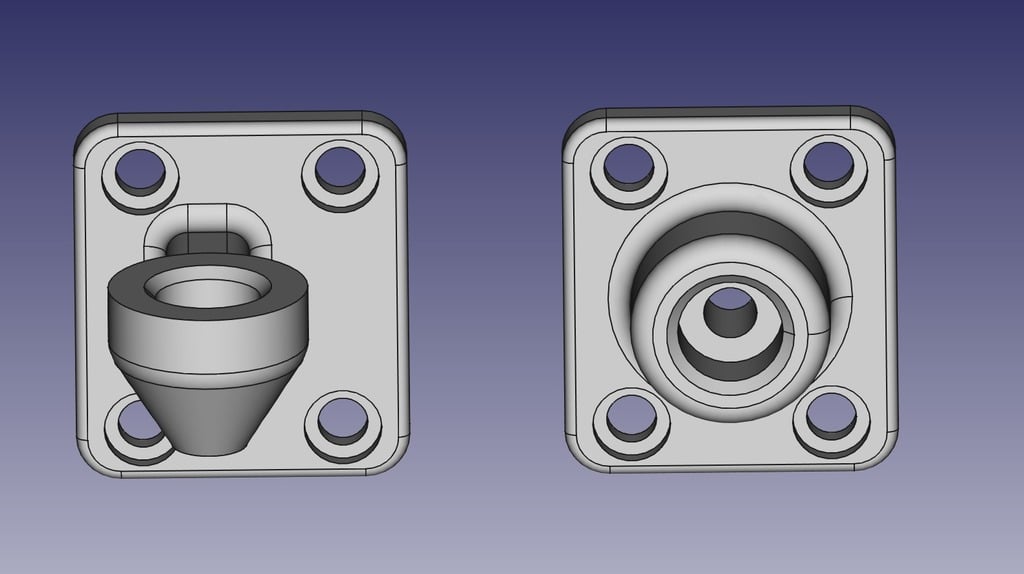

My printer is exposed to a fair bit of humidity and I don't have a lot of room for positioning my filament spool. As a result my filament absorbs a lot of moisture fairly quickly and tends to cause a lot of tugging on my X-carriage. This was my solution. Spool holder and desiccant sit inside a container with a push connect fitting, a PTFE bowden tube creates a fixed length bridge from the drybox to another push connect fitting mounted on the X-carriage. The mounts are sized for the push connect fittings to cut their own threads. It is possible to thread the fittings in far enough to be secure by hand. If you use a wrench, take care not to strip the plastic. Use a little bit (or a lot) of caulk or other sealant to fill any gaps on the drybox container. Be careful not to get any in the push connect fitting or bowden tube. Feeding filament into the extruder can be a little bit trickier with this setup, but I find detaching the bowden tube from the extruder end and feeding from above the push connect fitting works rather well. Same for clearing clogs, detach the bowden tube and pull the filament from above the fitting. BOM: (required) 1x Extruder End (printed) 1x Drybox End (printed) 2x 'PC4-M10' Push-to-Connect fittings (fits 4mm OD tubing with M10 threads) 4x M4-12 bolts (stock M4-8 X-carriage bolts were too short) 4x M4-8 bolts (reused from X-carriage) 4x M4 nuts 2 meters PTFE tube for 1.75mm filament (2mm ID/4mm OD) 1 container to serve as the drybox (optional) Sealant/caulk Dessicant

With this file you will be able to print "Reverse Bowden" Filament Guide System For Anet A8 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on "Reverse Bowden" Filament Guide System For Anet A8.