RIP 602 - Prusa MK3 Extruder Upgrade (R3 edit)

thingiverse

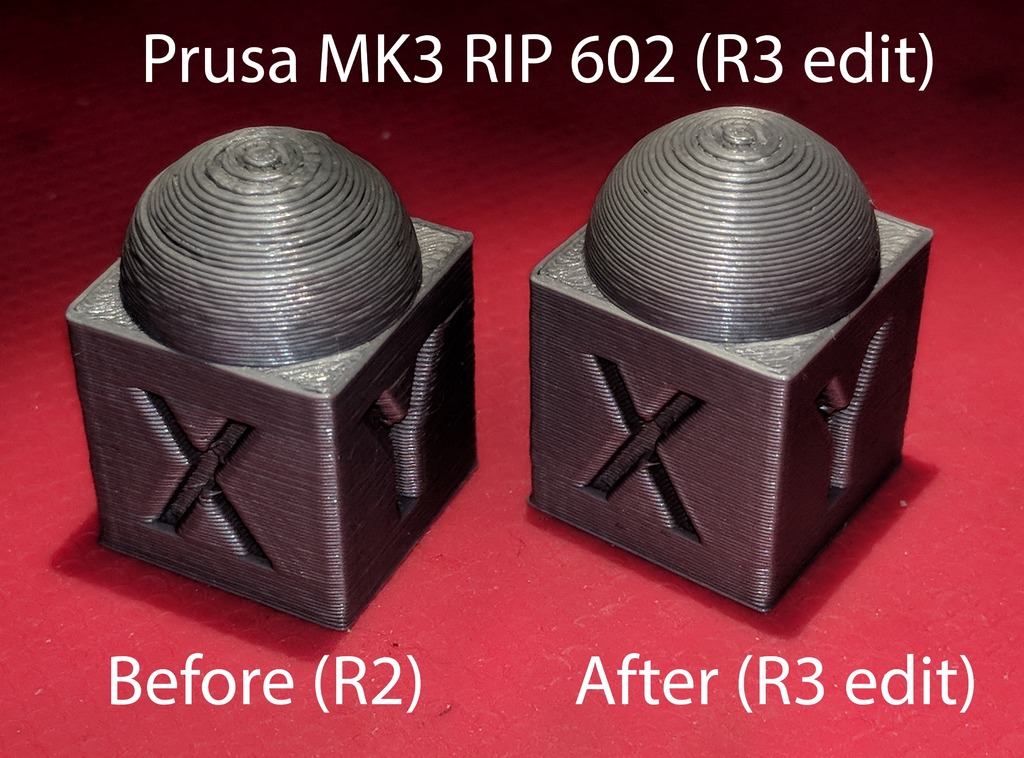

Issue 602: it is excessive inconsistent extrusion on MK3 and MK2.5, it creates a slight basket weave on all prints or wont extrude at all after retracting or doing circles; quite noticeable on layer heights at 0.3mm and round objects. There is some variation with 602 user to user and many of these issues have similar looking results such as over extrusion can be easily mistaken for 602 issue. Goal was to copy all things about MK2 extruder and apply to MK3 while still using MK3 parts. Airflow: Noctua airflow path has been widened as much as possible instead of funneled air like in stock. I think there was turbulence being caused by the cone so now air is free to pass without much resistance and hopefully more hot air is expelled. Took away the venturi hole. I understand the principal but this is not a venturi hole just a regular hole causing unwanted turbulence in addition to the turbulence caused by the cone shape. filament sensor cover updated, no more PTFE bit, just smaller hole with better designed pathway for filament. Filament sensor works as normal. I filled the hole to view the filament sensor that requires the tiny print to block light, that is no longer needed. Tension: my research and CAD work shows the gear teeth are about 25% into the filament pathway on each side, stock The MK2 hobbed gear teeth are 75% into the filament pathway while idle bearing pushes the other side, stock 75% into pathway seems a bit much, this means MK2 is maybe compensating tension from idler pushing it...? The MK3 does not have this compensation, gears are equal distance away from filament path. MK3 gears are in the center where it should be while MK2 gear looks to be into the filament path by a lot more. I offset stepper/gears 0.25mm to a 50% degree match MK2. I chose to only move half way, 0.5mm offset seemed too much. Reports from another user deep in this issue also suggested 0.25. This should increase tension on steppers gear and more tension can be added with the idler so long as the gear teeth allow. I also inverted the direction of idler so it flips down instead of up like MK2. idler updated to be flush on both sides for the metal rod 2cm long just be careful when inserting. Hope this helps, let me know if your prints show improvement. I know it won't kill 602 as intended but its a lot better than R2 extruder parts. link to 602 test print: https://www.thingiverse.com/thing:3296697

With this file you will be able to print RIP 602 - Prusa MK3 Extruder Upgrade (R3 edit) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RIP 602 - Prusa MK3 Extruder Upgrade (R3 edit).