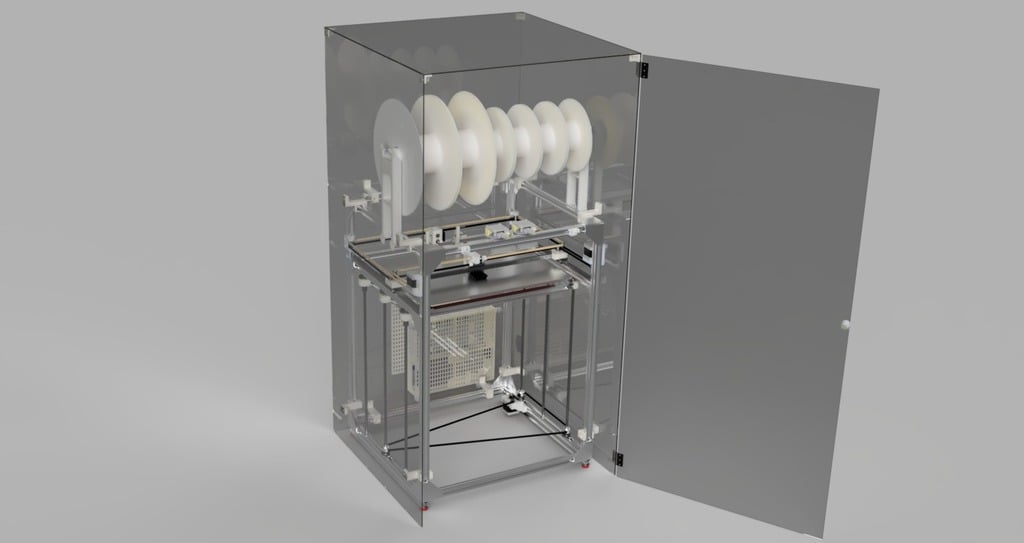

RK3D Tool Changer

thingiverse

If you want the STLs of the latest improved version, detailed assembly pictures with texts and tips, my custom DuetWifi settings and macros, answers to your questions, access to online 3D view of the raw design with tools for viewing and measuring; then you can send me 25$ here: (https://www.paypal.me/RajaaKahel) and leave me a message with your email address. Thank you. Commercial use is not allowed. keep an eye on the updates section in case I made an update so you remind me to send you the newer design. Don't forget to give credit if you used this design or any part of it. The free v1.0 version is no longer available. ------------ This printer needs common engineering sense when assembling, especially for measurements, alignments, clearances/tolerances. Most holes intended to be processed after printing. Don't use steel-core belts, they'll cause wrong print dimensions after a while. ------------ Basic facts: 1-This printer is big, printing dimensions: (X430mm) (Y330mm) ( Z about 440mm) 2- It doesn't require priming towers or wiping. 3- Fast, as the parts are compact, light and solid. 4- Can have many tools as you need. 5- Easy spool mount that takes normal and big spools, it works as a filament dryer at the same time (from the printer heat). 6- Cheap to make comparing with the results and quality you get. 7- Made with love and passion :) 8- A tool changer beats any dual or other systems, it's much faster, much cleaner and gives unlimited options. It's the future! 9- Integrated 3D printed Z-probe which is smaller, lighter and more accurate than most common sensors (repeatability of less than 0.003mm. (check the video below). Videos: https://youtu.be/KzgviMLx_bA https://youtu.be/_oo_ReEH_1o https://youtu.be/VZfM-kT_Zog https://www.youtube.com/watch?v=k3oQLOnQ1lQ https://youtu.be/6iCMdW4ovSc https://youtu.be/PgzQTpWUqfs Updates (for paid version): -10/12/2018 Lowered the left belt 3mm for a better assembly (less parts, more compact and more accuracy) thus idlers mounts and X carriage are modified. Optimized many parts for minimal support use when printing. Modified the v6 mount to be able to take THE NIMBLE extruder or other stuff and some improvements. Y carriages now have flush m3 screws. 21/12/2018 Some adjustments to the tool changer, Z motor mount and enclosure. Added magnetic door function. 13/1/2019 Added Nimble extruder adapter (lightest direct drive extruder available) and changed the Bowden guide design (no screws, snap it and slide it where you want). 15/1/2019 Changed the hotend mount design a bit for more strength when tightening the grip of the heatsink. 28/1/2019 Redesigned the electronics box. 12/6/2019 Designed a new part-cooling-shroud with integrated Z-probe which is smaller, lighter and more accurate than most common sensors. So now you have auto-leveling. Also removed Z endstop. 4/9/2019 The parking brush holder is now adjustable (for fine height adjustment or longer nozzles like Volcano etc). 13/10/2019 Redesigned the belt locks for a stronger grip, simpler and more solid design. ________ Beam lengths: 4X 2020 700mm. 5X 2020 500mm. 2X 2040 500mm. 4X 2020 460mm. Bed and X support: 2X 2020 310mm. 3X 2020 458mm. -------------- Parts: -DuetWifi: https://goo.gl/6rG7B7 -E3D v6 -THE NIMBLE extruder X2 (I'm using 95cm) https://zesty.tech/products/the-nimble?variant=33418107777 Or Titan extruders if you want to use Bowden (don't use small motors) X2: https://goo.gl/xd6mF2 -Capricorn XS PTFE (for Bowden) https://goo.gl/mvg5bj - (optional) NEMA 17 Smart Stepper X2: https://goo.gl/wp6FDx -Aluminum milled plate (460x350x6mm) : https://goo.gl/GbzLjf (they ship only to Germany, I used this service so they send the package to me in Sweden: https://goo.gl/j58hEL ) -XY limit-switches: https://goo.gl/qdX8Yr -24v 600W PSU: https://goo.gl/xRsbYF -24v 370*340mm Silicone heater: https://goo.gl/T9UNL9 -Idlers (5/13/4mm flanged bearings) F695ZZ X20 : https://goo.gl/2wjkq2 -Belt (don't use steel-core belts, they cause wrong print dimensions) : -250V Inlet module blug with fuse: https://goo.gl/wgAniD -24V blower: https://goo.gl/MJCR2r -MGN12H 500mm -MGN12H 450mm X2 -8mm Smooth rods 500mm X3 : https://goo.gl/hfKYn1 -SHF8 8mm X6 https://goo.gl/vTKQnb -1524-2GT-6 X1 https://goo.gl/3mecV8 -40 teeth GT2 Pulley 8mm Bore X3 https://goo.gl/9oEFWG -KFL08 8mm X6 https://goo.gl/fmWDsL -T8 Lead Screw Rod OD 8mm Pitch 2mm Lead 8mm Length 500mm X3 https://goo.gl/gNozrR -20t pulley for motors (5mm bore) X3: https://goo.gl/JTuPE6 -LM8UU X3: https://goo.gl/aFBsrD -5 holes 90 degree L bracket X28: https://goo.gl/1LMuVT -Wire organizer: https://goo.gl/UX8Tny -Rubber feet: https://goo.gl/wVDF4s -Mosfet: https://goo.gl/EDLpM9 -Tool changer magnets (12x5mm Hole 4mm, countersunk) http://tiny.cc/yoluaz -3-hole joint plate (you must chamfer the holes so the countersunk screws will be completely flat) X2 http://tiny.cc/36dvbz -Metal brush X2 https://goo.gl/SXfyPt (50mm OD) PVC pipe (length 584mm) ________ Use this to calibrate nozzles offset: https://www.thingiverse.com/thing:3193294 DuetWifi design by Phil Maddox https://grabcad.com/library/duet-wifi-1 PSU design by Serj Minin https://grabcad.com/library/power-supply-19 E3D extruder by E3D E3D V6 Hotend by Tico - https://grabcad.com/library/e3d-v6-hotend-3

With this file you will be able to print RK3D Tool Changer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RK3D Tool Changer.