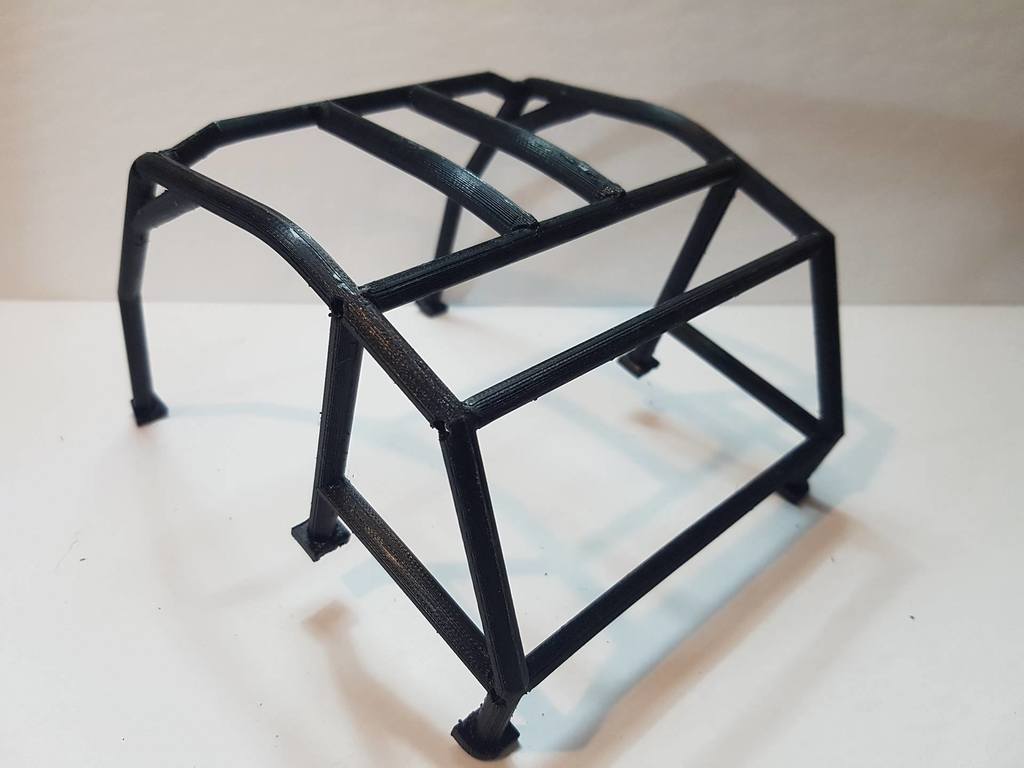

Roll Cage for the Ossum Jeep/My Remix

myminifactory

This is a roll cage for my remix of the Ossum Jeep but it will fit the original as well since they are both dimensionally the same. The cage is designed to use M2X3mm brass inserts, the kind that you heat up and melt into the plastic. There is an Amazon link below. There is really no way to go around this if you want a strong cage since the sections of the cage are printed in halves that glue together and a self-tapping screw would force the seam apart. An insert prevents this. You can choose to screw the cage together or screw and glue it using CA glue (strongest option) Each half section contains small intrusions. These are to be drilled and used along with some scrap filament for alignment. See instructions below. Materials and tools needed: -M2X3mm brass inserts (X14) https://www.amazon.com/a16041800ux0765-Cylinder-Knurled-Threaded-Embedded/dp/B01IZ15A5U/ref=sr_1_1?ie=UTF8&qid=1502015718&sr=8-1&keywords=m2+brass+insert -M2X4mm or M2X6mm Machine Screws (Mine were a 1.30mm hex socket head) (X14) -M2X16 Machine screw -Some scrap 1.75mm filament -A torch lighter -Needle nose pliers -7/64 (2.8mm) Drill bit -5/64 (2mm) Drill bit -CA Glue -200-400 grit sandpaper Instructions: 1) Print off all the files as they are and trim off the brims...Make everything look pretty! ; ) 2) There are three small intrusions on the flat sides near the bottom feet of the main cage components and along the the cross bars. Drill about 2mm in to these with the 5/64 drill bit but dont go through. 3) Sand the flat parts of all of the components to roughen them up for gluing. It is important to get a nice cross hatch on the smooth pieces of plastic to get a good bond. (Important Note: If you have too much filament sticking out then the halves will not butt up against each other completely and won't glue properly) 4) Use CA glue and pliers to glue in a 5-10mm piece of filament into each hole being careful to keep it perpendicular to the piece. After the glue dries cut each piece of filament so there is roughly 1.5mm sticking out. (Important Note: There are two different pieces to each section of the cage and that is why they are named left cage 1 and 2 and right cage 1 and 2. It is possible to glue the wrong pieces together so pay attention to the hole sizes around the top of the cage. The cage is designed to a piece with large holes glues on to a piece with small holes. The large holes allow the head of the screws to hide inside the cage section when assembled) 5) Run a very thin bead of CA glue along the flat side of each section of the cage then use the alignment pins to glue the sections together. be careful to align everything where there are no alignment pins. The cross bars are put together in the same way. 6) after all the sections have been glued into the various roll cage components then it is time to insert the brass inserts. Use the 7/64 drill bit and re-drill all the holes on the ends of all the cross bars and on the bottom feet of the main cage components. The drill bit should go in about 3mm 7) Hold the single 16mm M2 machine screw with needle nose pliers and screw an insert onto it so the threads are flat with the bottom hole of the insert. This prevents molten plastic from getting into the threads. Heat the insert up with the torch lighter until it starts to discolour. It does not need to get red hot. That is way too hot! Once you see a color change pull the flame away and wait a couple seconds. Insert the brass inserts into all the holes being careful not to move it side to side. The insert should go straight in, about 0.5-1mm past the end of the plastic and be held there until the plastic around it solidifies. 8) Screw everything together as shown in the pictures. The bent cross bar goes in the front and the straight ones in the rest of the locations. 9) Sand the flat areas on the mid bars and glue them together. These do not have alignment pin holes as they are small enough to properly glue together while holding them in your hands. These get inserted and glued between the most front cross bar and the middle one with the bend towards the back. The center to center distance should be about 46mm between the mid bars and the sides of the cage. 10) Use the drill guides to drill holes in the proper locations on the Jeep body. The front drill guide will not work on the original Ossum Jeep as it is designed to fit between the tub and the new (smaller) transmission tunnel. The rear guide will still work on top of the 1/4 panels. Use the 5/64 drill bit to drill your holes and bolt the cage down from underneath. (Important Note: The corner cut of the rear guide goes against the inner bend of the 1/4 panel. This puts the holes where you need them. The front guide should be pretty self-explanatory as it only slides into the footwell one way and sits between the tub walls, firewall and transmission tunnel. If you are putting this on the original Ossum Jeep then put a dab of paint where the insert is located on the front legs of the cage. insert the cage into the Jeep but don't let the front legs make contact with the floor. Insert the two most rear screws and allow the cage to pivot forward so the legs make contact with the floor and leave a trace of paint where the hole should be. Remove the cage and drill the hole.

With this file you will be able to print Roll Cage for the Ossum Jeep/My Remix with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Roll Cage for the Ossum Jeep/My Remix.