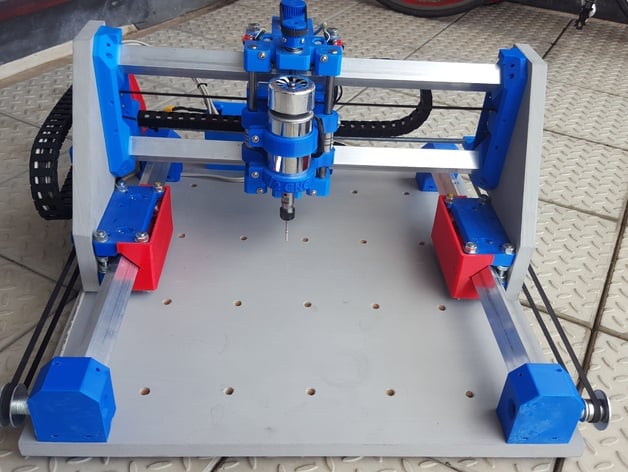

Root 2 CNC multitool router 3D printed parts

thingiverse

ROOT 2 CNC! Official Website! Join our forum and ask questions with our community.https://www.rootcnc.com Facebook Join Our growing Facebook Group to keep update with everything going on!https://www.facebook.com/groups/1023078667749894/ Current .Zip = 2.0.2 Update!!! R3 is here: http://www.thingiverse.com/thing:1750276 This is the latest version of Root CNC!! Join Us on Facebook! Upload idea's, photos and any updates https://www.facebook.com/root2cnc/ https://www.facebook.com/groups/1023078667749894/ Introduction I started this project to enable me to do another project which required sheet wood to be machined, (another 3D printer which I have been wanting to do for a while). without the large cost of out sourcing the tasks to a company. So I created this CNC named Root 2 to open up a endless amount of possibilities. Why make it open source? Since getting involved with 3D printing and the whole open source community, it has taught me many things and open doors which might not have been open without the added experience the community has given me. So I thought what a great way to put something small back into very thing what got me hooked in the magical world of CNC machine - the open source community. If you make one or remix it, I would love to see it! post some photos and show it off! =] Working Area = 331x305x120mm (X,Y,Z) Goals of this machine Create a expandable CNC machine capable to machine aluminum Use minimal different 3D printed parts Customization (Make it Bigger) Cheap Simple Use parts commonly used in DIY 3D printer Easily sourced parts Print Settings Printer Brand: RepRap Printer: I3 Redesign Rafts: No Supports: Yes Resolution: 0.25-0.35 Infill: 50% Notes: Print with 3-4 perimeters Print with ABS but PLA will be fine though your mileage may vary Videos Early Motion testing Movement Testing Cutting 5mm Acrylic Milling 12mm MDF BOM Plastic Parts 2x Root 2 CNC - Y gantry assm-1 Y-Axis Belt Clamp GT2 4x Root 2 CNC - Y gantry assm-1 Y Motion Bearing Mount 1x Root 2 CNC - Y gantry assm-1 Y Drag Chain Carriage 1x Root 2 CNC - Y gantry assm-1 X-Axis Carriage Y Drag Chain Mount 1x Root 2 CNC - Y gantry assm-1 X-Axis Carriage Y Drag Chain Mount Idler 2x Root 2 CNC - Y gantry assm-1 X-Axis Belt Clamp 2x Root 2 CNC - Y gantry assm-1 X-Axis Box Bar Mount 2x Root 2 CNC - Y gantry assm-1 Dirt Cover 1x Root 2 CNC - X carriage-1 Z-Axis Motor Mount 1x Root 2 CNC - X carriage-1 Z carriage-1 Spindle Upper Clamp 1x Root 2 CNC - X carriage-1 Z carriage-1 Spindle Lower Clamp 1x Root 2 CNC - X carriage-1 X-Axis Motor Mount 1x Root 2 CNC - X carriage-1 X-Axis Carriage Drag Chain Mount Idler 2x Root 2 CNC - X carriage-1 linear rail 90 bearing mount Y-Axis Carriage 1x Root 2 CNC - X carriage-1 3M Pulley 32T 5mm 1x Root 2 CNC - X carriage-1 3M Pulley 22T 8mm 1x Root 2 CNC - Ramps controller-1 Ramps Case Lid 1x Root 2 CNC - Ramps controller-1 Ramps Case Base 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Bar Mount 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Bar Mount Idler 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Bar Mount Idler Mirror 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Bar Mount Mirror 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Motor Mount 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Motor Mount Mirror 1x Root 2 CNC - Base and Y axis assm-1 Y-Axis Drag Chain 1x Root 2 CNC - Base and Y axis assm-1 3M Pulley 48T 8mm 1x Root 2 CNC - Base and Y axis assm-1 3M Pulley 24T 5mm 4x Root 2 CNC - Base and Y axis assm- Foot Electronics 1x Arduino Mega + Ramps 1.4 3x DRV8825 (Optional but preferred over the A4988) 3x Nema 17 Stepper motors (Get the Highest torque possible) 1x 60mm DC Fan 6x Endstop micro switches (KW11 I drilled the whole to 3mm to screw then in to the plastic parts) 1x DC Spindle (52mm Diameter - Get the highest wattage, you will be thank full later on) 1x Diode This is needed if using the heatbed Mosfet on the ramps to control the spindle - google Mosfet switching inductive loads for more information 4 core AWG26 cable (use for motor wiring and endstops) Fixings 4x M8 Penny washers Lots of M8 Standard washers lots of M8 Nuts 24x M8 x 25mm Bolts 2x M8 x 35-40mm Bolt 16x M8 Tee Nuts 2x M4 x 50mm Bolt 16x M4 Nuts 16x M4 Washer 16x M4 x 40mm Bolt Lots of M3 9mm Penny Washers Lots of M3 Nuts 10x M3 x 10mm lots M3 x 16,20,25,30,40 mm Lengths (good to have a selection on hand) Bearings 36x 608 Bearings 4x LM10UU Metal Work 2x Aluminum Box section (X-Axis) 25x25x496x3mm (W,D,L,T) 2x Aluminum Box section (Y-Axis) 25x25x496x3mm (W,D,L,T) 1x M8 Smooth Rod 580mm 8x M8 Threaded Rod 85 mm 1x M8 Threaded Rod 500 mm 2x M8 Threaded Rod 200 mm 1x M8 Threaded Rod 230 mm 2x M8 Threaded Rod 100 mm 2x M10 Smooth Rod 185 mm Motion GT2 Belt (Length depending on size of the of the machine) 2x GT2 36T Pulley 8mm Bore 1x 3M-210T-06 Belt 1x 3M-264T-06 HTD 1x GT2 16T Pulley 5mm Bore 2x Drag Chain 20 x 10 mm 1m Length Wood 2x Wood Side Panel 1x Wood Base CAM Software Generate the Gcode I use PathCam, free open source software with minimal settings to enter to get up and running. Its not perfect but still does a great job! see link for more information. https://github.com/xenovacivus/PathCAM FAQs FAQs What is the working area of this machine? 331x305x120mm (X,Y,Z) What Firmware or Software do you run on the Arduino Mega? I use Marlin the 3D printer firmware. only because I know my way around it very well. I have not used GRBL yet but would like to try it. Marlin has a strong community and most questions have been asked regarding it. Assembly Guild Animated assembly guild:https://www.youtube.com/playlist?list=PL5hghy18PulU0-F_gzihovUwgWx6q6PMu Update History Update #10 I've updated the file structure to hopefully make it easier to find parts. Also added the option for a NEMA 23 Motor for the Y axis! Update #9 Added a 65mm and 66.4mm Spindle Mounts as requested. Theses Are REV2 design which incorporate the option for a lead screw nut or normal M8 nut options in one design! Update #8 Removed Prototype parts (from update 7). Theses parts were to premature for released and have been removed - see Facebook conversation for any latest work. Update #6 Animated assembly video's, these are a work in progress for when I get more time. more will be added soonhttps://www.youtube.com/playlist?list=PL5hghy18PulU0-F_gzihovUwgWx6q6PMu Update #5 Added FAQ's at the bottom of this page, It will be updated as and when I receive a question. Update #4 Added the option to use the Dewalt 611 / DeWalt D26200 or any other 69mm Diameter spindle on this machine! (Untested - Awaiting delivery) Update #3 Added the following files to use 1 inch box section* instead of the 25 mm box. X-Axis Box Bar Mount INCHES Y-Axis Bar Mount INCHES Y-Axis Bar Mount Idler INCHES *Theses are untested though the slot has been increased by 0.4 mm from the original to accommodate the 1 inch box. Update #2 Join Us on Facebook! Upload idea's, photos and any updates https://www.facebook.com/root2cnc/ https://www.facebook.com/groups/1023078667749894/ Upload, Share and Learn! Update #1 Rev 1.1 updated .STL files Theses are updated file which will reflect the Plastic Parts BOM Blow Use theses new files. Part Improvement on; Spindle upper and lower mount tweaked - Placed the logo on upper file and blanked the bottom Y-Axis Bar mounts Tweaked - Added option for cable management to ran through the aluminium box section. this can be useful for the min and max end-stop cabling. Y-Axis Motion Bearing Mount - Increased area to allow for more motion to tighten up the M8 clamps nuts. (It was difficult to do before) Removed the pointless prototypes of the 3M pulleys and only uploaded the sizes required Special thanks Special thanks to the people who have given me the ideas to come up with this machine. There have been many hours of YouTube videos watched over a long period of time, many hours searching google and most of all many hours printing. I cannot comment on all sources of information but here are a few which standout; People and groups worth mentioning;https://github.com/CarlosGS/Cyclone-PCB-Factory for getting me into this in the first placehttp://reprap.org/ for giving me the printer which printed a printer. To which that printer, printed the parts for a CNC machine - to machine the new printer. Of which this printer helped print the new piece for a new machine! very fitting for the RepRep self-replicate philosophy.http://www.thingiverse.com/Rukey/designs/ great place for ideashttp://www.thingiverse.com/thing:49484http://www.thingiverse.com/thing:41594 inspired the first Mill (Root 1 which wasn’t released as it wasn’t great :P)

With this file you will be able to print Root 2 CNC multitool router 3D printed parts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Root 2 CNC multitool router 3D printed parts.