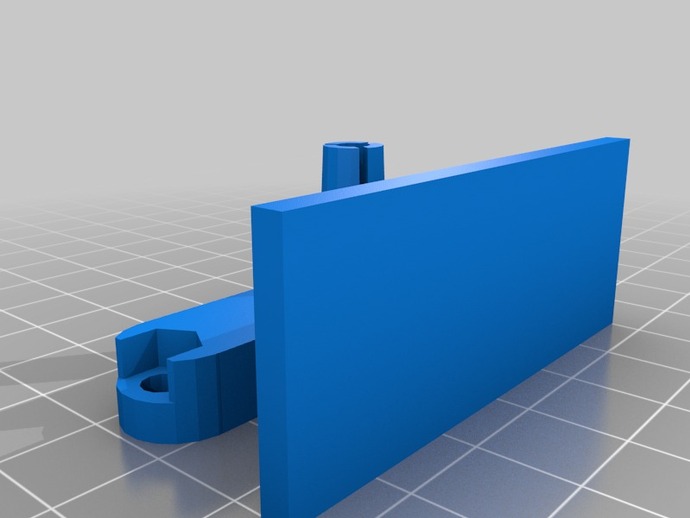

Rostock Bowden clamp offset

thingiverse

This is a modified bowden clamp for those with the offset holes in the wood piece. Instructions If you have the wood mount piece with the offset holes (hotend not in the center) you can use this mod. Print with ABS to make it more heat resistant. The original Rostock prototype uses PLA and it works okay too. Just make sure you don't pre-heat your hotend for too long without a fan pointing at it. The top is very thin so you may need to print slowly to allow each layer to cool enough before you print the next layer. If this is a problem, use bowden_hotend_cooldown.stl to add extra cooling time for each layer. Drill the clamp hole open to 4 mm. Cut the three slots open with a sharp knife if necessary. Add a stainless steel M8 nut on top but don't tighten it yet. Push the PFA bowden tube all the way into the clamp. Tighten the M8 nut, but not too tight. Hand tight should be enough. Drill the inside of the PFA tube open to 2 mm if necessary. Attach with two M4 nuts and Wade style plywood GrooveMount.

With this file you will be able to print Rostock Bowden clamp offset with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rostock Bowden clamp offset.