Rostock Max Extruder - DEPRECATED

thingiverse

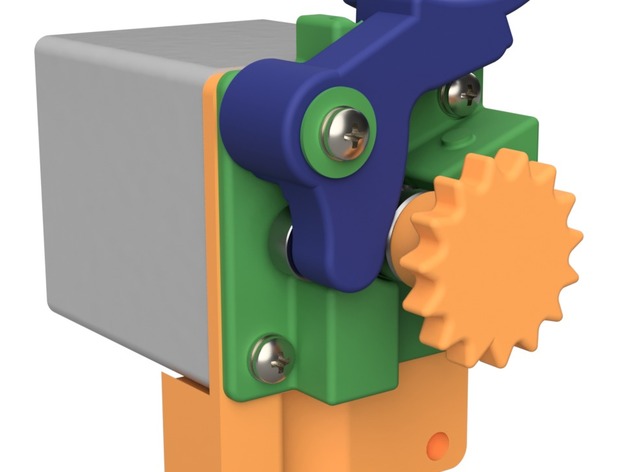

NOTE: I've deprecated this version and added a new one. The post where the bearing mounts on the lever arm can weaken and break off after a couple hundred hours of printing. I've updated the design to use a 3mm screw to mount the bearing to the lever. Much stronger and will last forever. Find the updated version here: http://www.thingiverse.com/thing:2013618 After experiencing a very, very high failure rate when printing Ninjaflex, I decided to go look for a solution. That's when I came across the extruder made by Singh336. It was good extruder indeed and I was able to successfully print both Ninjaflex and TPU. But, when I tried a TPE 80A filament, it jammed in the extruder the same way NInjaflex does with the stock EZStruder. TPE 80A is softer and more flexable than Ninjaflex I felt there were also a few deficiencies in Singh336's extruder so I decided to create my own. While mine is created from scratch, it is heavily based on the design by Singh336. Benefits: The lever arm won't twist like the stock lever arm. The Knob has a flattened spot to perfectly fit the stepper shaft. It has a mount. The feeder hole is closer and better aligned with the hob roller and bearing. The spring block is closer to the lever providing a more compressed spring and increased pressure on filament. The filament entry is taller and funnel shaped making it much easier to insert filament. All parts can be printed without supports. Suggestions: The lever arm must be strong and stiff. I recommend a high infill setting with honeycomb pattern.. The knob is a very tight fight and may require a little bit of filing to get it on. Use an 8mm socket and screwdriver style handle to screw the pressure fitting into the hole. Hardware: 3 - M3 x 8mm screws 1 - M3 X 25mm screw 4 - M3 washers 2 - #6 X 1.5 inch screws (for mounting. Or just reuse the original screws, but they are a bit long) 2 - #6 locknuts (can re-use original locknuts) 1 - 3x10x4 mm bearing (just re-use the original bearing from the lever arm) Results: I've successfully completed a 3 hour print with TPE 80A and the results are most excellent.

With this file you will be able to print Rostock Max Extruder - DEPRECATED with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rostock Max Extruder - DEPRECATED.