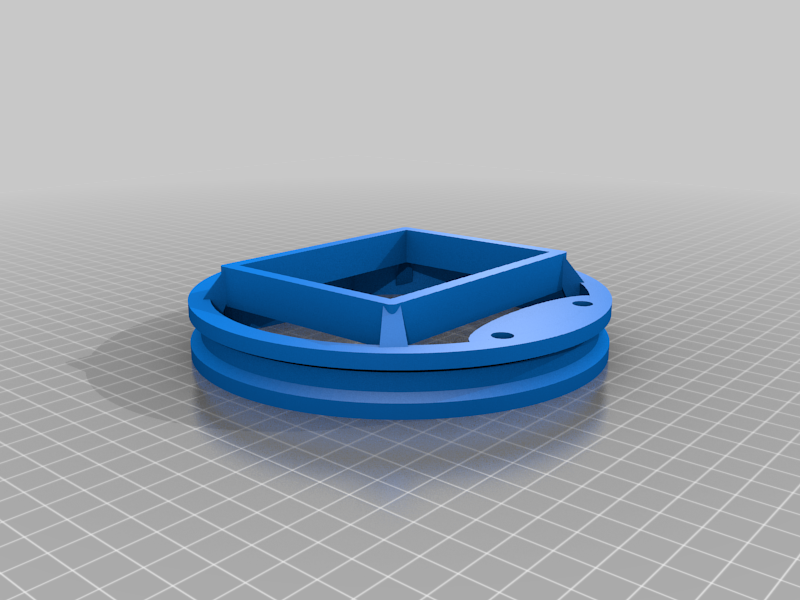

Rotary Cage for Nikor Steel Film Developing Tank

thingiverse

This is a pretty niche item, but I figured I'd publish anyway. I use a Beseler Color rotary base with 8x10 drums for developing my 4x5 sheet films. Rotary processing is super convenient and always gives very even and consistent results, all while using significantly less chemistry than tray or dip/dunk development. I have carefully calibrated a number of Zone System development recipes for 4x5 sheet film that I would like to use for roll films as well, especially now that I have a 6x9 roll film back for my Intrepid (see my profile for that Thing!). Unfortunately the 8x10 drums are not compatible with 35mm or 120 roll films. So I designed and prototyped this rolling cage that allows me to process roll films in my standard stainless steel Nikor development tank (the size that fits 1 roll of 120 or 2 rolls of 35mm), without losing easy access to the lid. After some testing with my chosen films (FP4+, HP5+, Ektachrome 100, and Ektar 100), I have found that my 4x5 times appear to translate perfectly over to roll films with this method. See the link below for a GIF of the design in action: https://www.reddit.com/r/AnalogCommunity/comments/kbjkj4/when_youve_been_rotary_processing_4x5_sheets_and/ To make this, you'll need print 2 of the "Half Wheel" .stl files, 3 of the "M6x140 Threaded Rod" files, and 12 of the "M6 Nut" files. I used 0.2mm layers of black PETG for the half wheels. Likely any filament and layer height would work. The half wheels do need to be printed with support from the print bed. I used three walls and 20% infill. Likely whatever you're already using as your default will work fine. The threaded rods and nuts are 0.12mm layers of yellow PLA. They require no support, but the rods have a really bad height-to-footprint ratio, so I used a 6mm brim to be safe. Tricky to prevent a failure here if your adhesion is iffy. When in doubt, a big brim, slow print speeds, and a bit of z-hop on retract will all help decrease your chances of failure. They aren't really bearing much load so they don't need to be incredibly strong, but I printed the threaded rods and nuts at 96% infill with three walls since it's not much material anyway. I am working on a v2 of this design that will replace the somewhat fiddly threaded rods and nuts with backpack style plastic buckles to hold the wheel halves together. I will publish it here when it's tested and working. Should be much faster and easier to use than the threaded rods. Special thanks to thing 193647 for providing the SCAD script I used to easily generate the threaded rod and nuts.

With this file you will be able to print Rotary Cage for Nikor Steel Film Developing Tank with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rotary Cage for Nikor Steel Film Developing Tank.