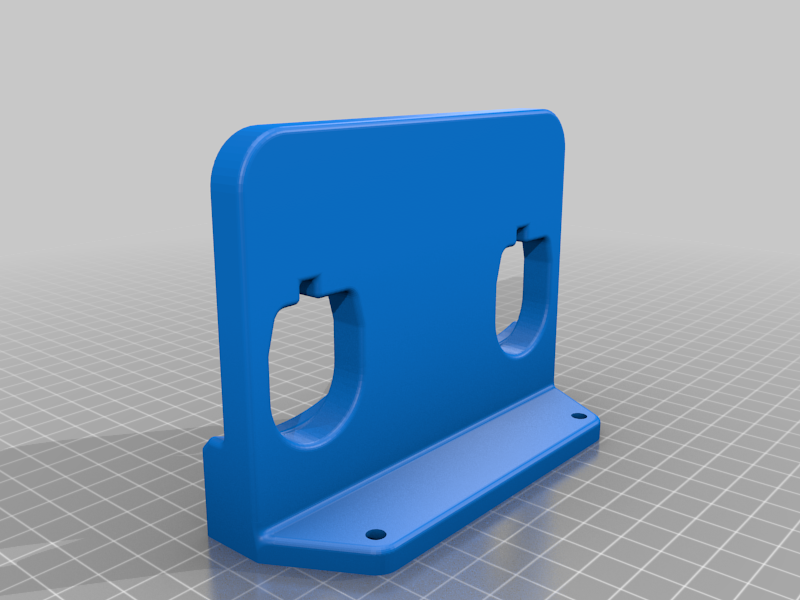

Ryobi 18V tool holders (Solid)

thingiverse

I want to give credit to the original designer for putting in all the hard work and creating these. One thing the creator said in the original thing (see original text below) was the designs were made hollow to save material. This is true on some of the models and some it is not. The other downside to doing this is you have nearly an addition 30% print time to save just a few grams of material. I will quantify my findings if you would like to see below, I'm sure nobody else will care as much as I did. So what did I do? I filled them all back in. I have also copied over the battery holders and a couple specialty mounts that did not change so you have a one stop shop still for most of the entire collection. I have added 'solid' to the end of the file names that have changed and 'original' to the end of the files I did not modify. (PS I'm not sure what happened to the scaling on my updates. if they come in huge print them at 10% and if they seem too small print them at 254%. I don't know what happened) MY ANALYSIS All my prints were done with 6 walls, 4 top, 4 bottom and 36% infill. Why 36% you might ask? I missed the 5 and saved my high strength PLA profile with 36 instead of 35. Back on track here. I estimated the time and material used in CURA to compare the original hollow models vs the solid and here are the results: 10° single holder hollow, 18:43, 216g solid, 13:48, 226g circular saw holder hollow, 30:33, 369g solid, 19:57, 339 10° slacker holder hollow, 18:39, 215g solid, 13:47, 225g 20° single holder hollow, 21:19, 260g solid, 16:39, 297g Flat mount hollow, 6:24, 74g solid, 5:11, 73g Strimmer mount hollow, 22:51, 290g solid, 18:13, 328g The issue with them being hollow is there is a second set of walls being built inside the print along with support structure in the cavity to support the new bottom wall that is floating inside the model. I felt it was better to just fill the inside with infill rather than support material that is not typical structural. ORIGINAL TEXT FROM ORIGINAL CREATOR The Ryobi cordless tools are excellent tools but I got tired of them lying on shelves looking untidy. So I designated a section of wall on my garage for them. I ended up with 8 different designs. Single battery holder Double battery holder Hedge trimmer holder Strimmer/weed wacker holder Circular saw/vacuum holder Flat holder for torches/flashlights 10 degree holder for drill, impact wrench, small air pump and sander 20 degree holder for reciprocating saw All printed with Gizmo Dorks excellent 3mm ABS filament on my Lulzbot Mini. Most of the designs are hollow to save plastic and most can be placed on the bed plate in a way that doesn't need any support. The hollow ones print really well on my printer with no support even though the surface facing the tool has very little support - must be due to all the changes in section. Note: for the air pump the slacker V2 model works better for me - others are too tight a fit on my air pump. I just loosened up the circular saw holder and stiffened the projection to make it less prone to fatigue (11/11/16)

With this file you will be able to print Ryobi 18V tool holders (Solid) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ryobi 18V tool holders (Solid).