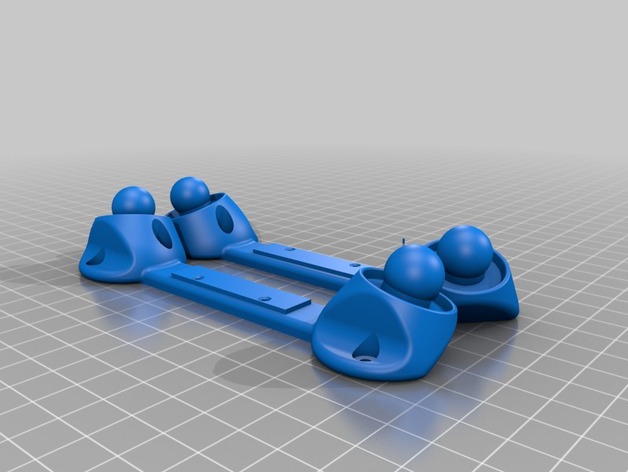

S500 - No-Frustration Landing Gear

thingiverse

Problem S500 frame is great, mainly for its carbon-fiber reinforced arms. But it has few things I don't like. One of them is terrible landing gear. I've got a version with plastic landing gear - separate legs which prone to crack on any relatively hard landing. And its tedious to replace it. Yes, there are just two screws, but anyway it takes time when you are at the field. Solution I've came-up with the idea of ball-socket attachment for the legs. That means it will not crack on the harsh hits. If the dynamic load is bigger than what the ball joint can handle - it just pops off. But even if the leg broke (straight axial hit) - you just push-on the new one and you back to flying in a second. The ball-socket itself should never broke, especially when printed from ABS with high infill it will be stronger than any other parts of your frame. There are two versions of ball mounts. One is full-frame, another is side-only. I've just got to the limits of the part size which my Kossel Mini can print normally (got troubles with geometrical accuracy). Decided to go with side version, for which two parts has more compact footprint. And it is easier to put on (don't need to remove the battery mount CF rods). The side-only version got a stump for RGB LED stick (greetings to Cleanflight users!). The stick mounted nicely with M2.5 screws (these used to assemble the drone frame itself). http://www.ebay.com/itm/WS2812-WS-2811-5050-RGB-Rainbow-LED-Driver-Module-Board-5V-8-Bit-for-Arduino-/181923377900 Two version of legs length: 100 mm or 200 mm (for the case you mount a huge camera gimbal). So now you can switch between legs lengths momentarily. Don't get frightened with their thickness, they are hollow inside (basically 0.6 mm shell, with the only reinforcement at the socket area). 200 mm legs made with thicker socket reinforcement to provide the same level of retention as 100 mm when the leg tip gets a side hit, please be careful putting them on (might be to hard when doing for the first time after the printing). Recommend to print legs from PLA, it is more springy then ABS and holds better. Both materials appear to work well with this design (I am using Hatchbox). Easier transportation for your quad, you may just remove legs when moving around. So can put your quad in a big laptop bag, etc. (please checkout my other thing - low-profile battery mount http://www.thingiverse.com/thing:1782491) Tested in the field flying. While tuning PIDs for new drone setup had over 20 harsh landings, 0 legs broken! Awesome!!! The only disadvantage is bigger weight. 75 grams of original for legs against 130 grams of ball joint mounts with 4x200mm legs. But the saved time of flying at the field is priceless. Since you are here! So you've got S500 frame? You also might be interested in programmable LED boards of my own design: https://www.ebay.com/itm/112821970650 Happy Flying! Print Settings Printer Brand: RepRap Printer: Delta Kossel Mini Rafts: No Supports: No Resolution: 0.2 Infill: 70..100 Notes: Use brim when printing legs! Clean it off with knife and sand paper when done. I've tried both Hatchbox ABS and PLA. PLA seem to work better, since it is more springy and less prone to layer separation (what is very good for a legs socket design). Enable cooling when printing legs from PLA, especially if you print just one leg. The leg design, except its socket section, is just a thin 0.4mm shell (two passes of a nozzle), so layers stack up quickly and it might deform under its own weight if not cooled.

With this file you will be able to print S500 - No-Frustration Landing Gear with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on S500 - No-Frustration Landing Gear.