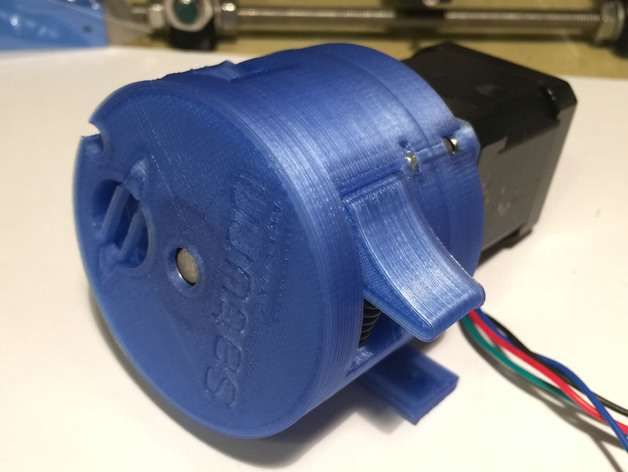

Saturn Extruder - A compact 3mm planetary geared bowden extruder

thingiverse

I wanted to make a nice, compact extruder for 3mm filament, and direct drive extruders just don't have enough torque. So I designed this compact, planetary geared bowden extruder with a roughly 5:1 gear ratio (similar to a wade extruder) but far more compact. There is a quick release handle to easily change filaments, and M3 mounting holes which I use to mount on a kossel. The planetary gears are based on Emmet's gear bearing and print assembled, although the rest of the extruder needs assembly. Video: https://youtu.be/8W2CMN2Lwik Source code at https://github.com/alexspeller/Saturn-Extruder Print Settings Rafts: No Supports: Yes Resolution: 0.2mm Infill: 50% Notes: PLA is probably better than ABS for the gears. You definitely need supports for printing. Print the whole plate STL, or if printing individual STLs ensure they are oriented correctly! Instructions Bill Of Materials 623 Bearing qty 3 608 Bearing qty 2 Spur gear, 8mm ID, 12mm OD or maybe Hobbed gear 8mm bore Stiff spring, 20mm long, 5.5mm ID, 7.5mm OD M3 nut qty 11 M3x8mm socket cap screw qty 10 M3x12mm socket cap screw qty 4 M3x25mm socket cap screw qty 1 M8x25mm hex head bolt 8mm threaded rod cut to 13mm long Push fit connector Nema 17 stepper motor 5mm shaft Planet gear assembly Step 1: Planetary gears Free up the gears with some pliers, be careful not to break them Put nuts into the nut traps in the centre gear, and loosely add M3x8mm screws Place the gears on the stepper. Fasten with 4 M3x8mm screws Tighten the 3 grub screws onto the motor shaft Add some silicone lubricant onto the gears Insert the 3 623 bearings into the planet gears Carrier gear assembly Step 2: Carrier gear assembly Insert 3 M3x8mm screws through the holes, tighten the M3 nuts and ensure the nuts are secure in the nut traps Insert the M3x25mm bolt into the hexagonal hole Tighten the spur gear onto the bolt. It should be exactly the width of a 608 bearing from the end of the screw Idler Step 3: Idler Insert the threaded rod through a 608 bearing and push into the cutout in the idler Top case Step 4: Top case Insert M3 nuts into all the nut traps on the side of the case Insert a 608 bearing into the depression on the bottom of the case lid Insert the idler into the hole. Screw the M3x25mm screw through the idler to act as the pivot Use pliers to put the spring between the 2 posts Planet carrier positioning Final assembly Step 5: Final assembly Screw the two halves together with 4 M3x12mm screws Screw the push fit connector into its thread with needle nosed pliers

With this file you will be able to print Saturn Extruder - A compact 3mm planetary geared bowden extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Saturn Extruder - A compact 3mm planetary geared bowden extruder.