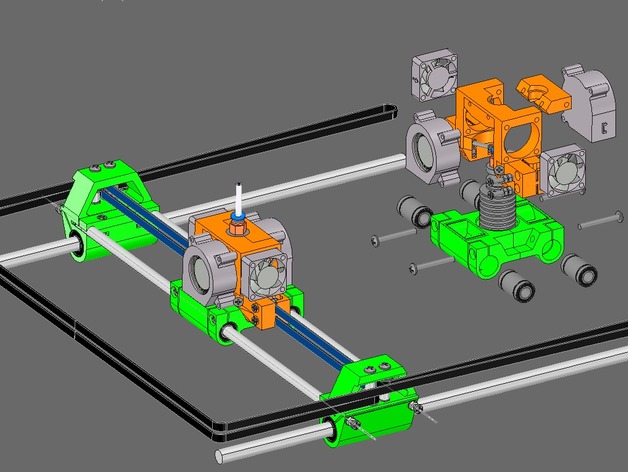

SCOUTcorexy XY_Stage XCarriage 8mm YCarriage 10mm HorizontalRods SingleHotend

thingiverse

NOTE: This version has a flaw, namely the airflow from the lateral axial fans doesn't reach the critical section of the hotend's heatsink, that is the first few fins closest to the heater block, unless you would design yourself a shroud that redirects the air to the lower fins. The 10mm designs overcome this flaw). NOTE: I am working on the 10mm version of the SCOUTcorexy 3D printer XY stage (http://www.thingiverse.com/thing:1606042) and the features of the XCarriage that have been developed for that one are quite incompatible dimensionally with the 8mm version. I can provide that XCarriage here with LM8UU holes instead of LM10UU but everything else will remain the same. Please follow the 10mm design, I will leave this here just for inspiration/reference. I have started designing an XCarriage for Bowden setups and Horizontal Rods that overcomes most of the static and dynamic errors that affect printing during the accelerations/jerks/etc of a 3D printer (discussion here: http://forums.reprap.org/read.php?1,668254). Here’s the Album with explanations added to each print screen where I am explaining the features of the design: https://is.gd/JQ5c0k Sketchfab 3D model with exploded view here: https://sketchfab.com/models/4ed5cc9d9e7b48cf8f739fa350ba49e5/embed DETAILS: X uses 8mm rods and LM8UU bearings Y uses 10mm rods and LM10UU bearings belt is gt2 Hotend is a clone of E3Dv6 axial fans are 30mm radial blowers are 4020 type all in all the XCarriage is very symmetrical and any forces applied during accelerations, jerks, etc, are evenly distributed so that the nozzle remains as fixed as possible. PRINTABLE Area: X -> 72% of YRod length (275mm for 350mm Rods) Y -> 78% of XRod length (275mm for 340mm Rods) Z -> 82% of ZRods length (270mm for 330mm Rods) Features: 60mm XCarriage (the Belt-Catchers go inside the YCarriages so they are not wasted space); Belts go in straight line and in the same plane from YCarriages towards the XCarriage; Belts can be tensioned with simple screws and dome-nuts pressing on the belt, forcing it into the niche designed for it; belts can be independently tensioned; Hotend supported both upside carriage and lower side by the 4 screws; Dual-30mm fans for coldend cooling; Dual-30mmfan (or squirrelcage blowers) for part cooling [still very undecided here]; Hotend Mount is quite easily detachable by unscrewing the bolts that clamp the bearings, and another tool can be swapped pretty quickly; TBD: 1) some way to remove wiggle/play from the linear bearings 2) design it for dual hotend [...] Cheers, Flo.

With this file you will be able to print SCOUTcorexy XY_Stage XCarriage 8mm YCarriage 10mm HorizontalRods SingleHotend with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on SCOUTcorexy XY_Stage XCarriage 8mm YCarriage 10mm HorizontalRods SingleHotend.