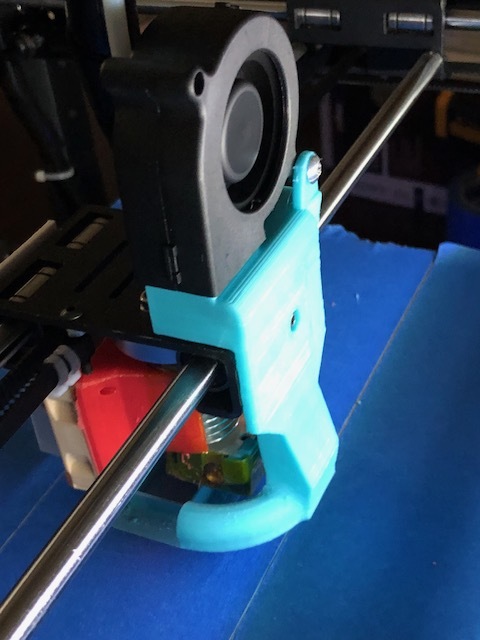

Semi-circular e3d/j-head fan duct cooler for Flying Bear P905

thingiverse

e3d/j-head v6 semi-circular 50x20mm blower fan duct This semi-circular 50x20mm blower fan duct is designed by re-mix two models - FlyingBear P905 Turbo Fan Cooling system and one of the semi-circular from Thingiverse. The top half is from "FlyingBear P905 Turbo Fan Cooling system" and the bottom half is from a semi-circular Anet style that I can't seem to find right now. This fan duct is designed to fit an e3d/j-head v6 hotend from this mod https://www.thingiverse.com/thing:2772682. Then, these modifications are applied: 1. Change the blower fan hole to fit a 50x20 mm blower fan 2. Increase the fan duct side by 1 mm to be a bit stronger 3. Increase the fan duct top part by 2 mm so that it is a bit simple to print the bottom layer 4. Increase the fan duct narrow areas to be a bit stiffer but all internal remains the same The fan is Sunon 50x20mm blower fan - https://www.digikey.com/product-detail/en/sunon-fans/GB1205PKV1-8AY.GN/259-1317-ND/1021167- and is a bit more quieter than those cheap 10 mm fan. I had tried to print with ABS so that it would be a bit more heat resistant. But due to the shrinkage of ABS, there is crack in the narrow areas and I don't want to increase the wall thickness. Therefore, printed with PLA and then spray heat resistant paint over it. Before you paint with heat resistant paint, adjust the fan duct as following: 1. Attach the print fan duct 2. Heat the bed to 80 degree 3. Lower the fan to as close as possible to the bed 4. Let it heat up the fan duct so that you can adjust lower blower part 5. Adjust the lower circular blower part of the fan duct until there is equal clearance on both side 6. Remove and paint with heat resistant paint. 7. After dried, re-attach and heat the bed again to 80 degree 8. Make sure it still has the same clearance 9. Let the bed heats the fan duct a bit so that it becomes more heat resistant. Then let it cool. You can repeat this a few time if you want to. After this, the fan duct shouldn't droop when you heat the bed to 80 or 100 degree. It seems like heat resistant paint needs some heat to cure and be stiff and strong. The image shows two bridge print tests with 100 and 50% fan setting. v4: The change in version 4 includes: 1. 2mm on the bottom of the top half to allow more layer 2. Extra thickness on the side next to the extruder. (After one year printing, it cracked.) 3. Increase the wall to 0.8 mm on the side With the above change, I can now print with eSUN ABS+. To print this with eSun ABS+, use setting as: Layer Height: 0.1mm Wall/Top/Bottom Thickness: 3mm Top/Bottom direction: [90, 0] Infill: 50% Temp: 235 Bed Temp: 110 Fan: 50% Support: Yes (Touching Buildplate) Brim: 10mm

With this file you will be able to print Semi-circular e3d/j-head fan duct cooler for Flying Bear P905 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Semi-circular e3d/j-head fan duct cooler for Flying Bear P905.