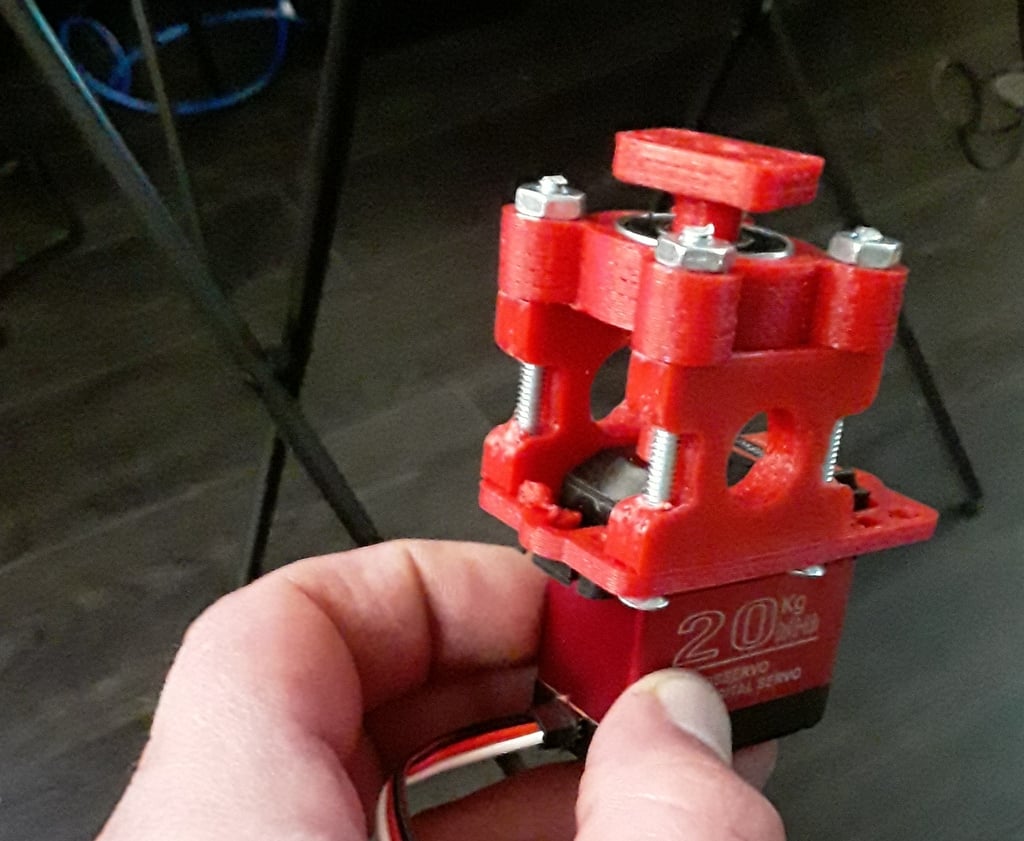

Servo Block 3d printed! Fits MG995/MG996R, other similar servos. 608 bearing required.

thingiverse

Work in progress. As per request, I'm uploading my current version of my attempt at saving $25-30 per servo for the aluminium parts that can be found on amazon, etc. ** The shaft may or may not work out for you, I had best results in PETG printed at a weird slanted angle, and with a m3 set screw shoved down into it, but even then I'm not happy with the strength. If you put any force on it and have printed the shafts in the easiest way (vertically) it WILL eventually fail. I will update with a more refined version of this experiment, but here ya go. I recommend 80% infill, PETG only, and the use of a drill bit to get the holes just right during assembly. You will need a 608 bearing for the part labeled as such. I used a vice to press the part in. The tolerance is pretty tight, so I would suggest plan on forcing it in, or printing with the bearing in after a few layers if you want to get creative. Again, totally a work in progress. Only failures in all kinds of stress tests were with the Shaft, so if someone finds a nifty way to get that thing to hold up after a while, please remix and let me know! / ** Non-3d-printed parts needed: -- 1x 608 bearing ( I've been using very cheap ones I salvaged from fidget spinners I found a good deal on) -- 4x aluminium screws - I'm guessing these are 0.5 mm dia but to be honest I just used what I had lying around and used a hacksaw to cut off the ends to size after screwing in, this maintains the overall shape factor and rigidness (I chose not to 3d print the entire thing so that it remains modular, just as the aluminium legit version of this servo accessory is) -- 4x Nuts to accompany the 4x screws -- Some sort of screw or bolt to hold the servo body to the plate. I've found that it holds up fine with just a couple zip-ties to be honest, as the rest of the assembly somehow holds everything together nicely regardless. ** Update 7-10-2019: The horn/arm will last longer if you print it horizontally, but I've since scrapped the whole 608 bearing for that particular portion, by gutting the bearing itself and keeping the outer ring. I'm almost done assembling the quadroped legs this thing was originally intended for, so once I have enough field tests with it I'll post my findings and modified files... So far the bracing and movement has been optimal on bench tests, so I'm optimistic that this was a wise decision, as the shaft can be printed much thicker and sturdier in PETG this way. However, I still would roll back to the original design with the in-tact 608 bearing by machining a shaft out of aluminum, I just currently do not have the resources to do such a thing with precision. I suppose the alternative would be to obtain larger inner diameter bearings, but to be honest the bracing effect seems to solve all of the play problems I made this thing to solve in the first place, as long as the printed shaft is ground and sanded finely.

With this file you will be able to print Servo Block 3d printed! Fits MG995/MG996R, other similar servos. 608 bearing required. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Servo Block 3d printed! Fits MG995/MG996R, other similar servos. 608 bearing required..