simplifyed modular Zero Gravity Extruder with Titan or Dual Drive (or any Nema17 mounted-extruder drive) Remote Direkt Geared Double Drive

thingiverse

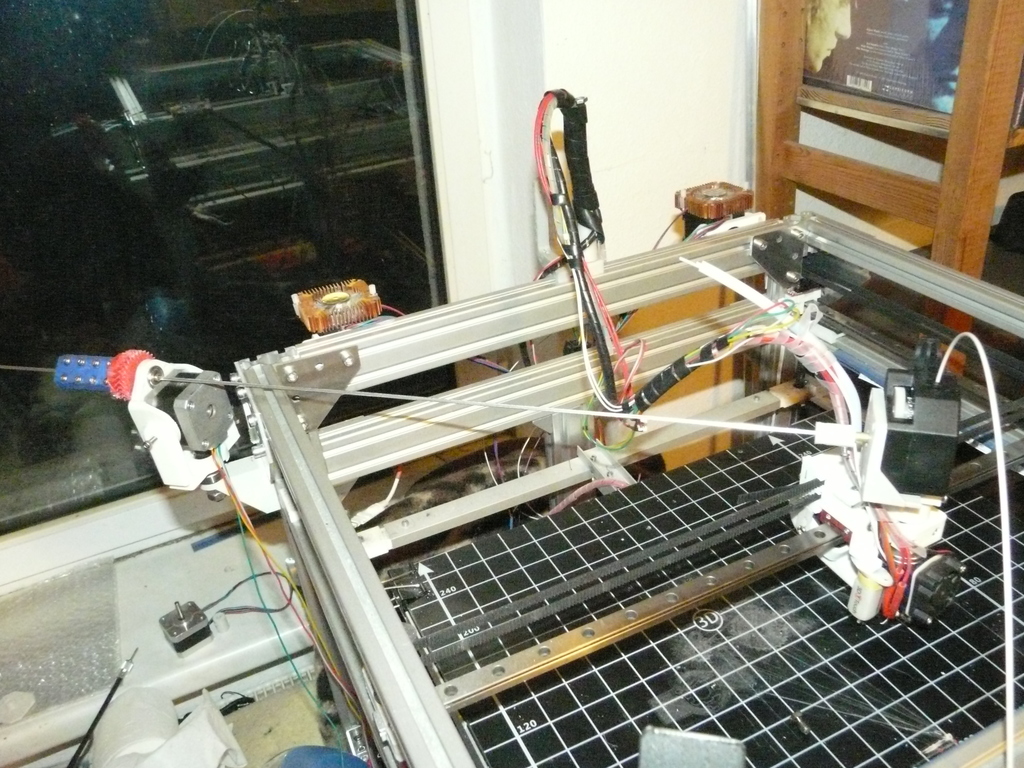

https://youtu.be/Msw1_5msjjo This project draws inspiration from https://www.thingiverse.com/thing:2348263, but offers a simpler approach by reversing the torsion spline's orientation: Gudo & Neotko stab the spline through the printhead, while this one stabs it through the motor. My design seems more modular. The advantages: -Working with the torsion spline fixed to the motor makes housing with a roof challenging, but still feasible. -This design can be applied to any printer, not just those specifically built for it (like flat-tops). -Fits better in printers with large build areas compared to their overall size. -Less mass is moved with the carriage since the skid is heavier than a fixed unit. -It doesn't come with an extruder drive design, but serves as a mount for your chosen driveblock. It's simply a matter of exchanging the Nema17 on the carriage for a lighter construction and a Nema besides the housing. -With luck, the only thing you'll need to build is the shoulder piece. The only things that need to be changed when switching to another extruder drive are the drive holder/head piece (and with luck, not even that). For example, the difference between the Titan holder and the Double Drive holder is just the position of the filament-exit. So it's easy to construct another one. -You can change back to your former bowdenextruder within the time you need to heat your nozzle. And that's no exaggeration, because all you have to do is remove 2 screws and put back your ptfe bowden tube. The disadvantages: -You'll need a lot more space in one direction and a bit more in another direction (check out the photo). -With a misplaced motor and without a spinner (not provided yet), your printer will try to drill-stab you and remove your eyes. The ugly truth: -Because of its concept, double extrusion with two motors and two nozzles would be too high and probably not possible. How this is meant and how to mount it: -Look at the 4th picture (advance to the sequence that fits against the text): A simple printhead with a bowden extruder. This is what you probably have before and what you'll have back after removing just two screws. The short ptfe will remain there, going all the way through to the extruder drive, giving it a well-guided filament's path (so it's still a bowden extruder, but so short that even flexible filament will work - still unproven, but it worked with a pipe just a little shorter). -So a piece called shoulders holds a bearing there (10mm bore bearing, 15mm diameter, 4 or 5mm width). -From the downside, a piece called throat is pressed into that bearing. On the upper side of the throat piece is a hole for a 3mm screw for mounting with the head. When this is mounted, you have a turnable, tight connection between the shoulder part and the head (which is the holder for your extruder drive) and the ptfe tube going all the way through. Last part is to mount the shoulder part against your carriage and we are done (last Foto). Ready already? Well we still have the motor section here: https://www.thingiverse.com/thing:3476085. And the mounting of the driveblock against the head-things (which should be done before the mounting with shoulders and stuff - I changed sequence in description because of the modular concept in it). For that, you need a 5mm bore bearing and a 5mm tube with 4mm bore, 40 to 50 mm long. The bearing is placed into the Driveblockholder (should fit tight), a brass tube is going through; onto this you mount the Gear of the driveblock usually sitting on the Nema17 axis. My brass tube fits so tight in the bearing that there is no need for another fixation. The outer end of the brasstube needs a little hole for the connection with the coupler-piece. Which is already forced onto that 2mmx2mm square spline. And that's it. Thing is still in testing. The Titan works ok (was the first try of forcing the bearing onto the brass tube and it bend a little; furthermore the concept of the titan - part of the pressing part is sort of *mounted* against the motor axis, and that does not work well with the brass tube. The DoubleDrive Bondtech Clone worked extremely well and smooth after I turned the Motor Gear with the wider side outward. Otherwise it fits to tight. Have still to undergo tests with flexible material.

With this file you will be able to print simplifyed modular Zero Gravity Extruder with Titan or Dual Drive (or any Nema17 mounted-extruder drive) Remote Direkt Geared Double Drive with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on simplifyed modular Zero Gravity Extruder with Titan or Dual Drive (or any Nema17 mounted-extruder drive) Remote Direkt Geared Double Drive.