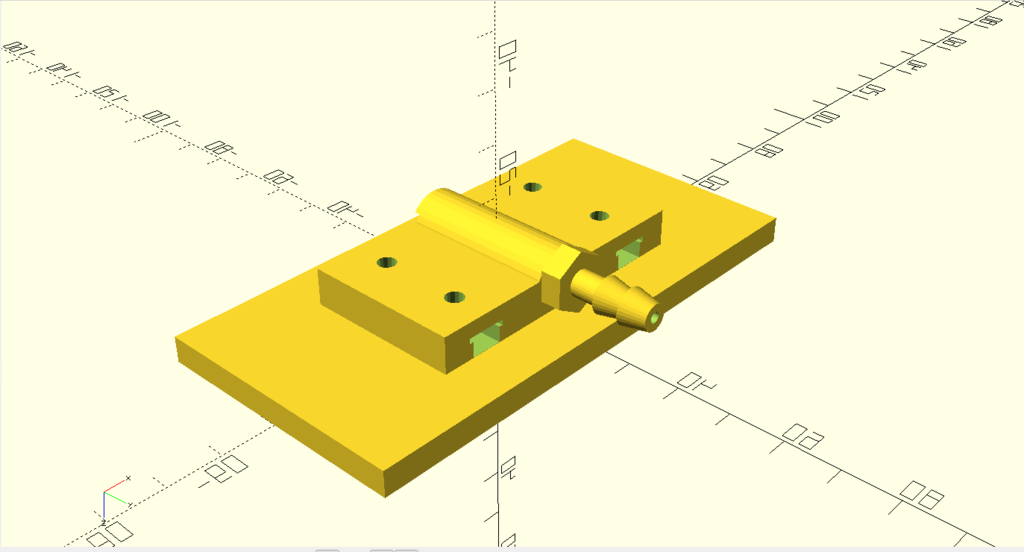

Slide printing build plate

thingiverse

This is an experimental an untested thing! OpenSCAD code will be released upon testing. You are playing with a pressure differential here, so be careful. Also, the exposed edges of the slide will be little vicious knives, hungry for blood and FEP. Long story short, by downloading this, you agree that my part in this is done. It's also released into the public domain, with or without attribution. I'd also like to say, again, that this is experimental and the printing geometry is likely going to be problematic. Still want to do this? Great! There are two major ways to deal with this, depending on if you have a printable gasket material that you want to use. If you want to print the gasket the stl is provided, but it's probably not worth it. The ideal has crush vanes, but OpenSCAD and I had a disagreement about generating them. Otherwise just cut a gasket from rubber and adhere it to the platform. Positioning is not critical so long as it is uniform. The check valve/barb is designed for a .177"/4.5mm/BB steel ball and a 4mm ID 6mm OD o-ring, similar to the 9262K102 from McMaster Carr.(I love them, but you can probably find much cheaper) This will allow for a 6mm tube attached to a vacuum source to pull a vacuum to hold the slide. I do not warrant that it will hold through a print . . . as I said this is experimental. I suggest a syringe, not a pump, as there is always the possibility of contamination. The release port is designed to be covered by a rubber flap, cut from any convenient source, and pinned with two <1mm pins (like 0.8mm paper clips, which are common enough) on one side. The vacuum should keep it closed and simply prying up the unpinned side will release the seal. The plate is designed to be mounted to the Easy Leveler (https://www.thingiverse.com/thing:3096818) and requires its use. In addition to the listed requirements, four M3 nuts and washers are required, and it is possible longer bolts than the stock Easy Leveler bolts would be required. Do not overtighten! I also **highly** recommend you install a stop on your Z-axis: https://www.reddit.com/r/AnycubicPhoton/comments/jbezkd/addition_of_zaxis_upper_limit_switch/ Specs: Slide Dimensions: 75mm x 25mm x 1mm Barb/Valve Sizes: M8 thread, 6mm tubing Gasket Thickness: 1mm This design is experimental and untested. Released into the public domain.

With this file you will be able to print Slide printing build plate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Slide printing build plate.